High-flatness metal surface electrochemistry jet flow modification processing device and method

A metal surface and processing device technology, applied in electrochemical processing equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

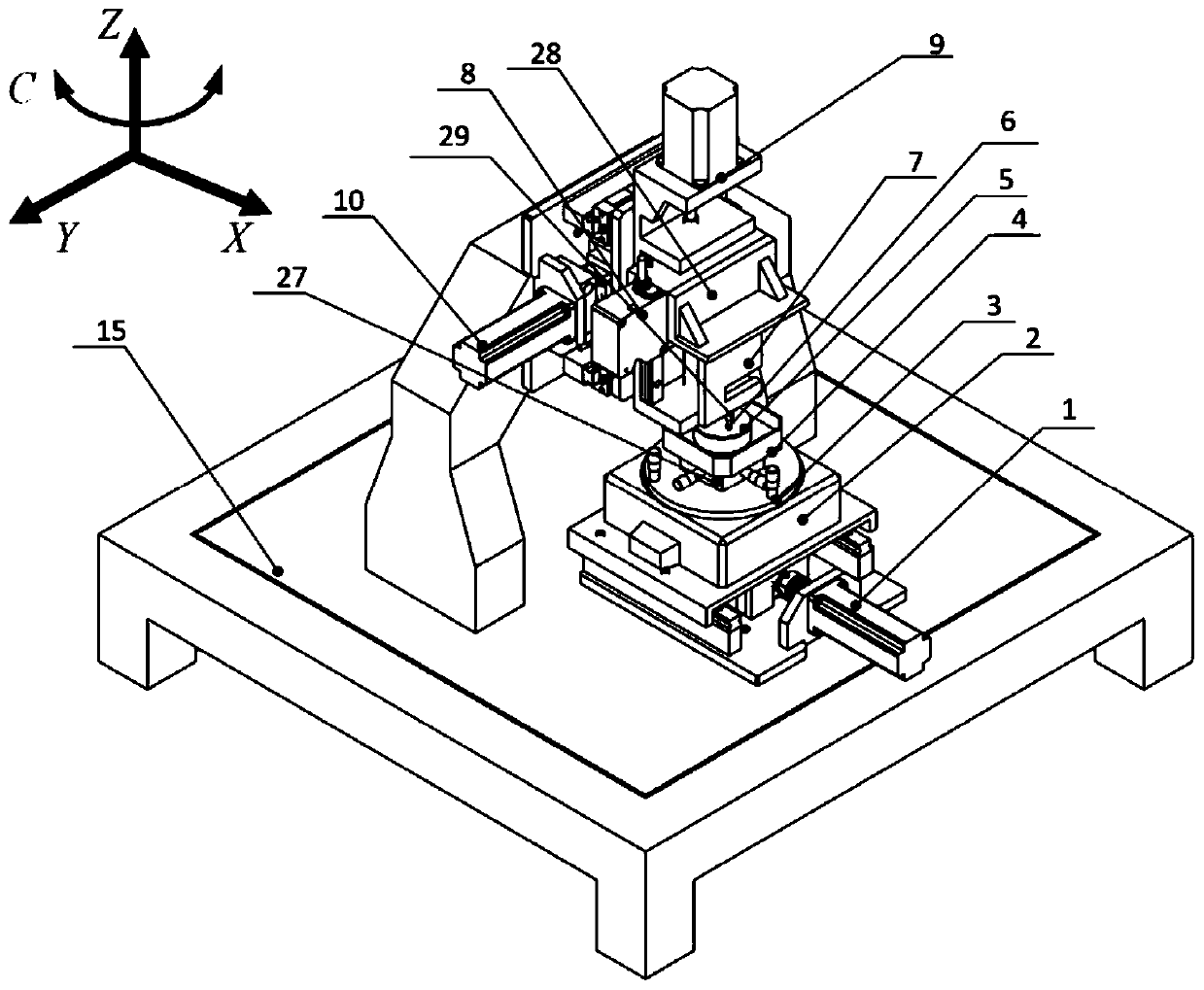

[0069] The invention provides a high-flatness metal surface electrochemical jet modification processing method and device. The invention is mainly aimed at the modification processing of the metal workpiece surface, and can realize the shape prediction and high flatness modification processing of the metal surface material after processing . The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

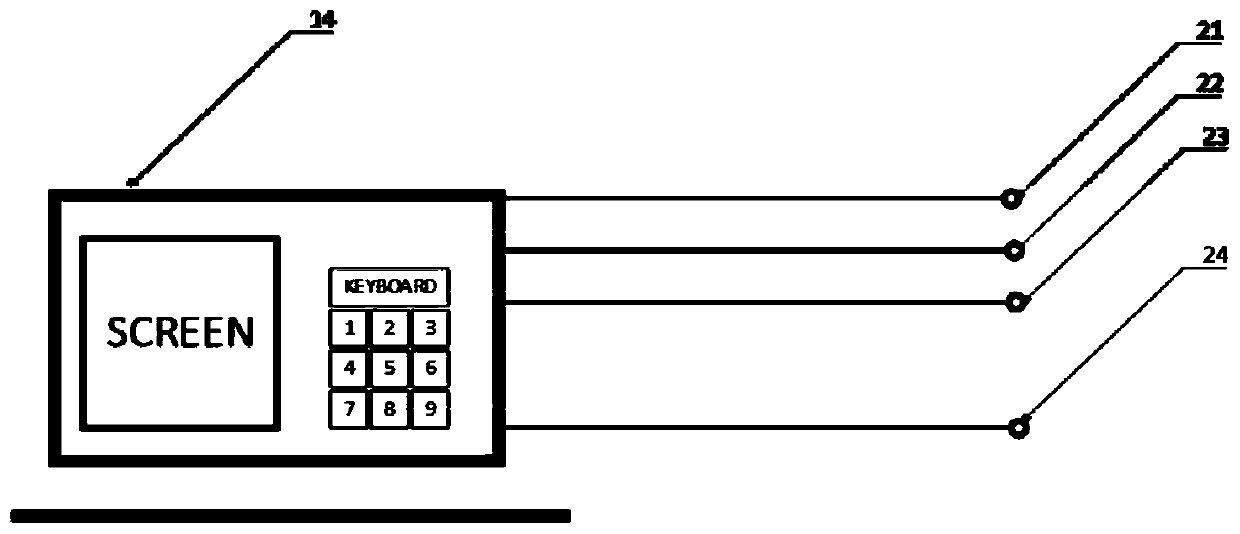

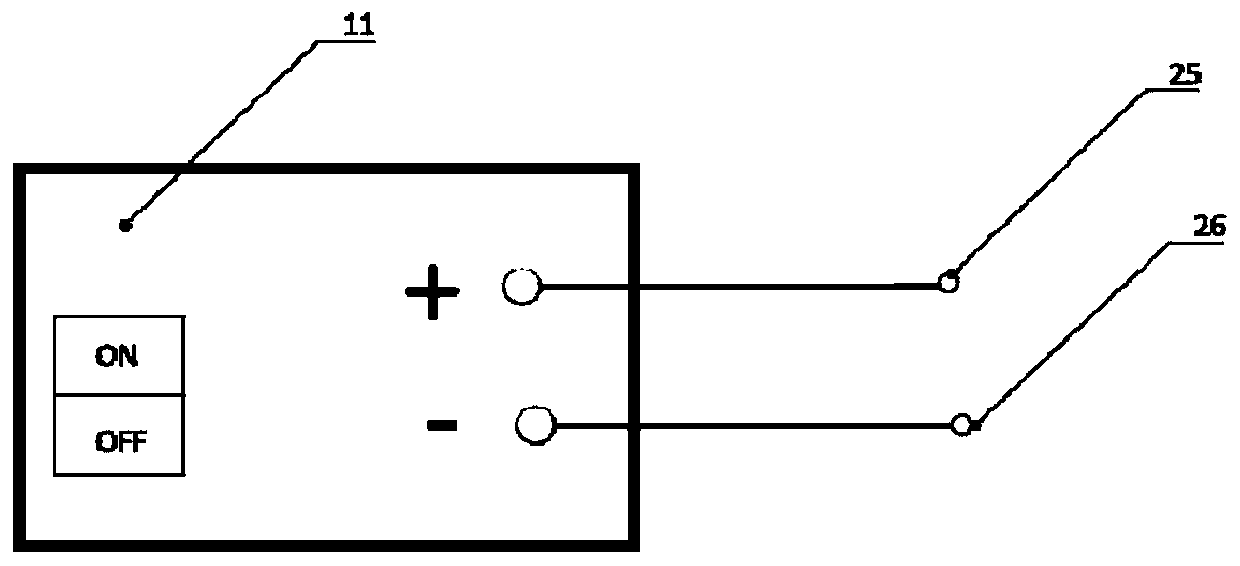

[0070] A high-flatness metal surface electrochemical jet modification processing device, including an X-direction linear guide mechanism 1, a C-direction turntable 2, a leveling device 3, an adapter plate 27, an electrolytic cell 4, an electrode 6, a force sensor 7, and a laser Displacement sensor 8, Z-direction linear guide mechanism 9, Y-direction linear guide mechanism 10, pulse power supply 11, electrolyte hydraulic circulation system 13, motion controller 14, optical platform 15, control line inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com