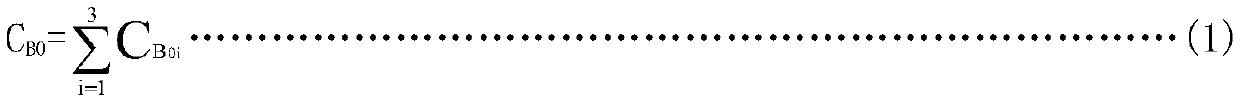

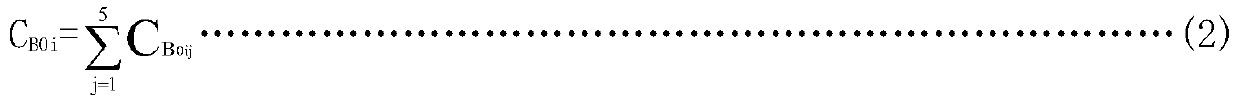

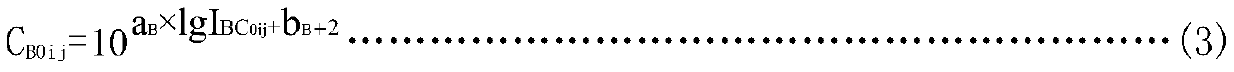

Method for detecting mold resisting properties of electrical household appliances by ATP biofluorescence lgC-lgI standard curve method

A technology for household appliances and detection methods, which is applied in the field of antibacterial function detection of household appliances, can solve the problems of inaccurate counting of mycelia, impossibility of quantitative testing, and large impact, so as to improve scientificity and versatility, break through the limitations of qualitative analysis, The effect of reducing the influence of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0139] The present invention will be described in detail below in conjunction with preferred embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0140] In this embodiment, the antifungal performance test of a sample of the same material as a refrigerator liner prepared by adding a nano-silver antibacterial agent is taken as an example for illustration.

[0141] The specific detection method is carried out according to the following steps:

[0142] (1) Sample preparation and pretreatment

[0143] 1.1 Control sample: injection molded from sanitary high-density polyethylene (HDPE), the size is (50±2)mm × (50±2)mm, and the thickness is not greater than 5mm; each strain test uses 6 groups of samples, of which 0h Three groups were used for the contact and 48h incubation tests, with 5 samples in each group.

[0144] 1.2 Antib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com