Processing technology of high-pressure-resistant polyethylene water storage and drainage board

A processing technology, polyethylene technology, applied in soil protection, infrastructure engineering, objects with hollow walls, etc., can solve the problems of easy silver wire, unstable compressive performance, unsatisfactory tensile and compressive performance, etc. , to achieve the effect of preventing silver wire and floating line, improving the anti-deformation ability, and improving the anti-indentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

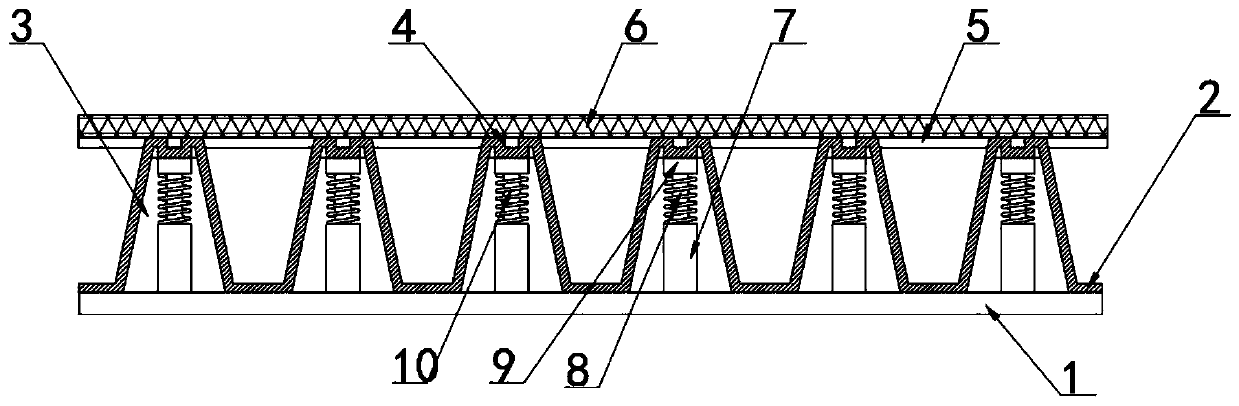

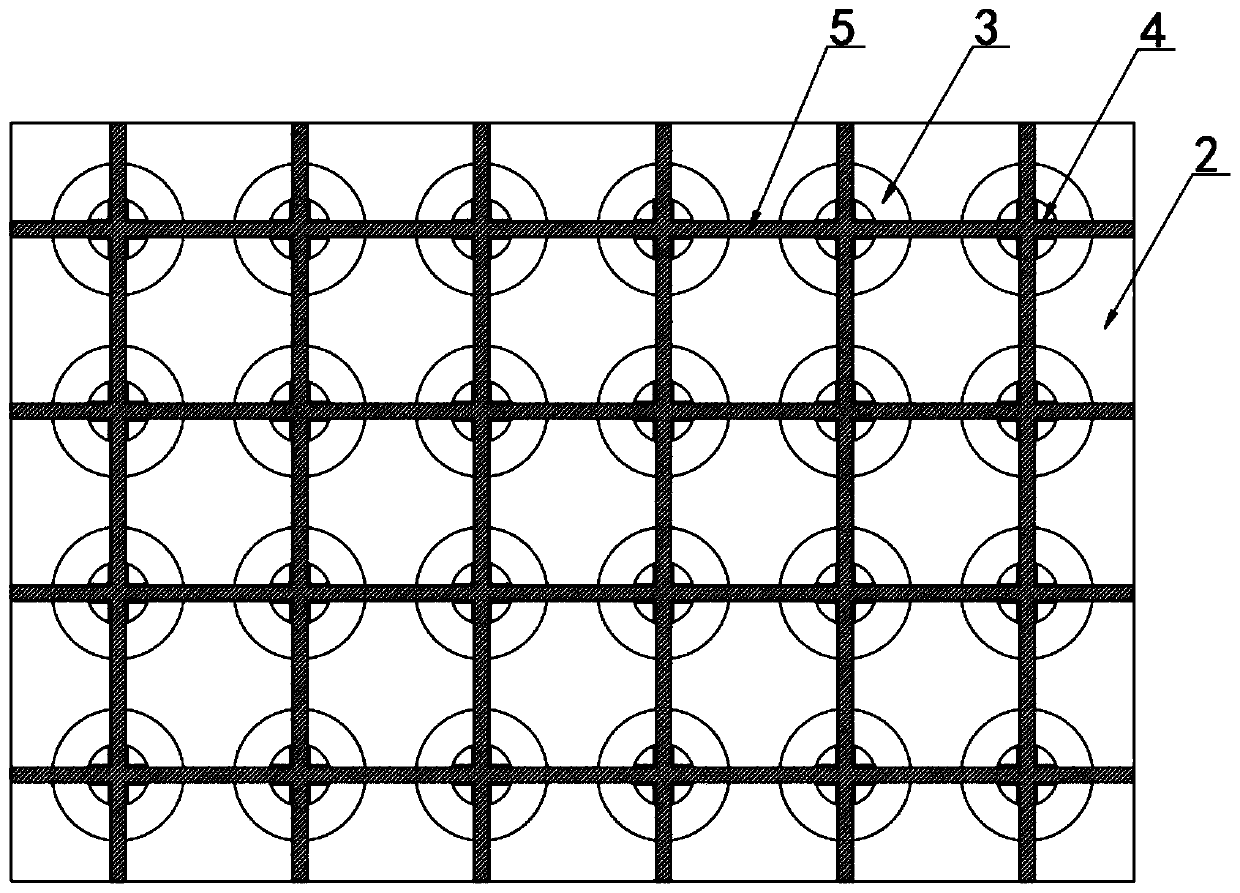

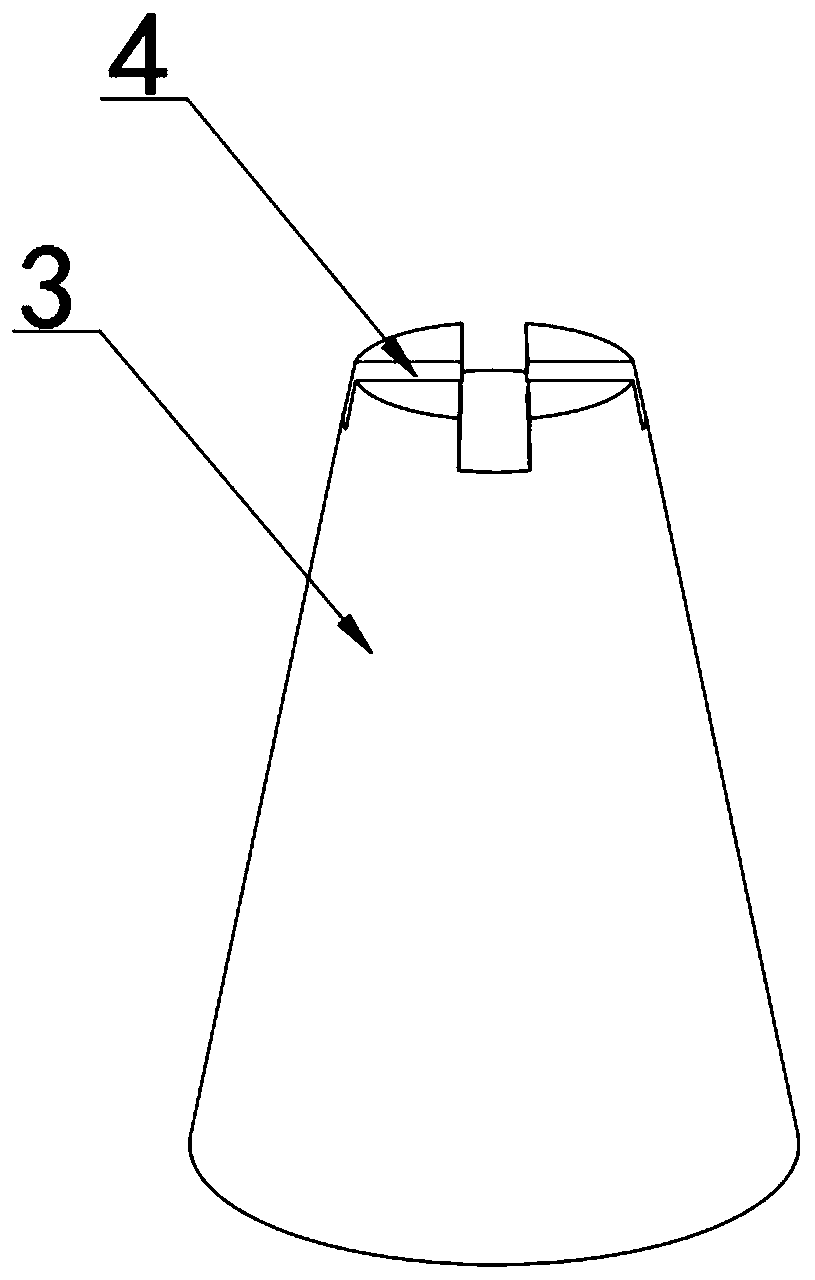

[0029] according to Figure 1-6 The processing technology of a high-compression-resistant polyethylene water storage and drainage board is shown, including a base plate 1, a support plate 2 is arranged on the top of the base plate 1, a supporting circular platform 3 is provided on the surface of the supporting plate 2, and the top of the supporting circular platform 3 is The first fixing groove 4 is provided, the top of the first fixing groove 4 is provided with a support frame 5, the top of the support frame 5 is provided with a top plate 6, and the inside of the supporting round platform 3 is provided with a support column 7, and the support column 7 The top is provided with a support rod 8, the top of the support rod 8 is provided with a support head 9, a spring 10 is arranged between the support column 7 and the support head 9, and the top of the support head 9 is provided with a second fixing groove 11;

[0030] Specifically include the following steps:

[0031] S1: Prod...

Embodiment 2

[0041] Different from Example 1, during the preparation of support plate 2:

[0042] (1) In terms of parts by mass, weigh the following components to prepare raw materials: 85 parts of polyethylene, 7 parts of phenolic resin, 10 parts of sodium fluoroborate glass powder, 15 parts of resin lens scraps, 8 parts of quartz sand, and 30 parts of silicone resin , 25 parts of wood flour, 7 parts of toughening agent, 1.1 parts of hyperbranched flow modifier and 8 parts of glass fiber;

[0043] (2) According to the mass ratio of the above-mentioned raw materials, polyethylene, phenolic resin, sodium fluoroborate glass powder, resin lens scraps, quartz sand, silicone resin and wood flour are put into the mixer in turn, and the linear speed is 15- Under the condition of 18m / s, stir and mix at high speed for 30-50min to obtain mixture A, and transfer the obtained mixture A to a hydrothermal reaction kettle, then add toughening agent and hyperbranched flow modifier and mix with mixture A s...

Embodiment 3

[0045] All different from Embodiment 1 and Embodiment 2, in the process of preparing support plate 2:

[0046] (1) In terms of parts by mass, weigh the following components to prepare raw materials: 85 parts of polyethylene, 10 parts of phenolic resin, 17 parts of sodium fluoroborate glass powder, 20 parts of resin lens scraps, 10 parts of quartz sand, and 35 parts of silicone resin , 30 parts of wood powder, 10 parts of toughening agent, 2 parts of hyperbranched flow modifier and 15 parts of glass fiber;

[0047] (2) According to the mass ratio of the above-mentioned raw materials, polyethylene, phenolic resin, sodium fluoroborate glass powder, resin lens scraps, quartz sand, silicone resin and wood flour are put into the mixer in turn, and the linear speed is 15- Under the condition of 18m / s, stir and mix at high speed for 30-50min to obtain mixture A, and transfer the obtained mixture A to a hydrothermal reaction kettle, then add toughening agent and hyperbranched flow modi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com