Water making engineering structure based on modular filter layer

A modular and filter layer technology, which is applied in water conservancy projects, sea area projects, buildings, etc., can solve the problems of ecological environment damage, diversion channel blockage, and inability to be directly used, so as to facilitate disassembly, maintenance or replacement, reduce construction steps, The effect of reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

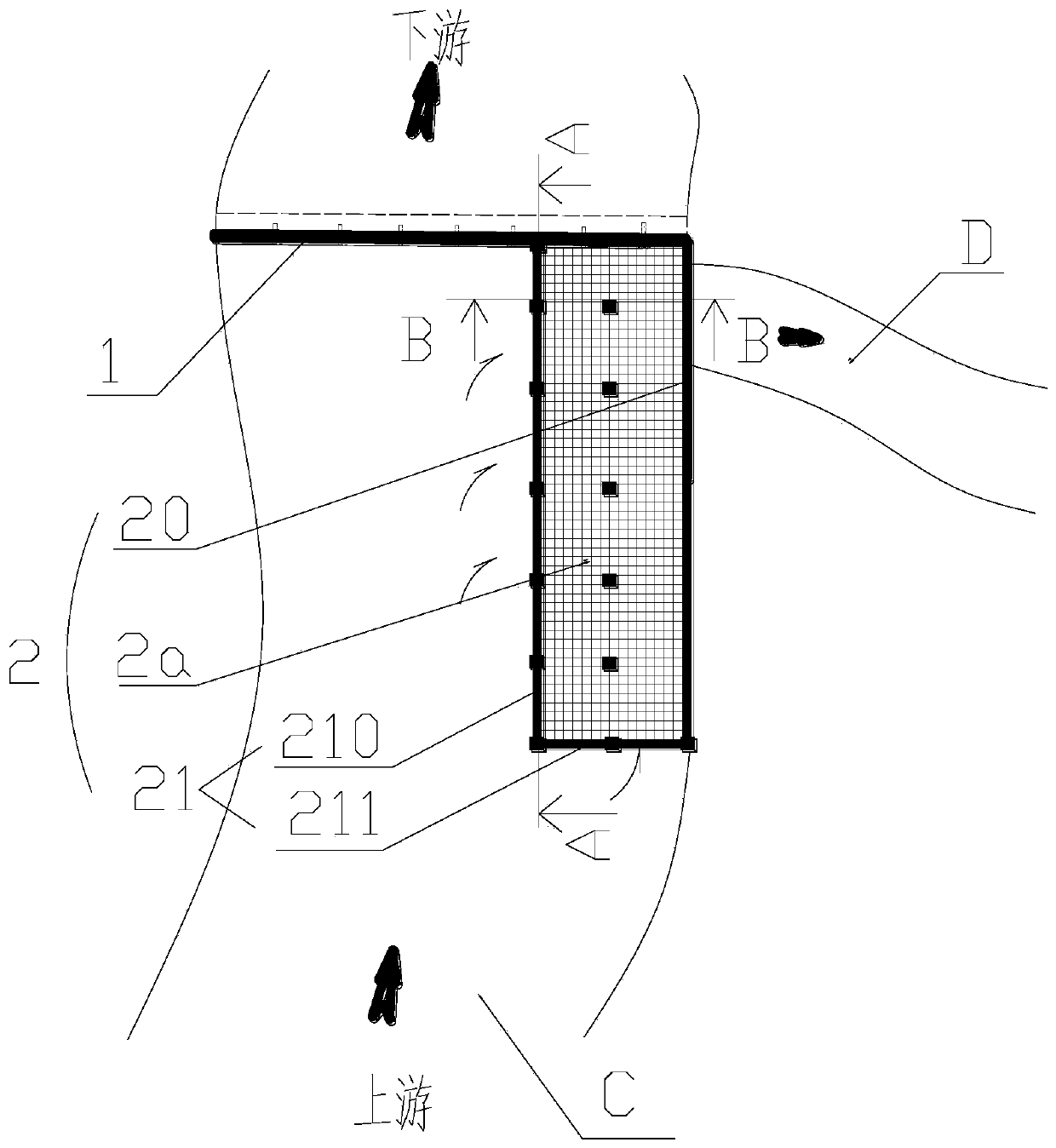

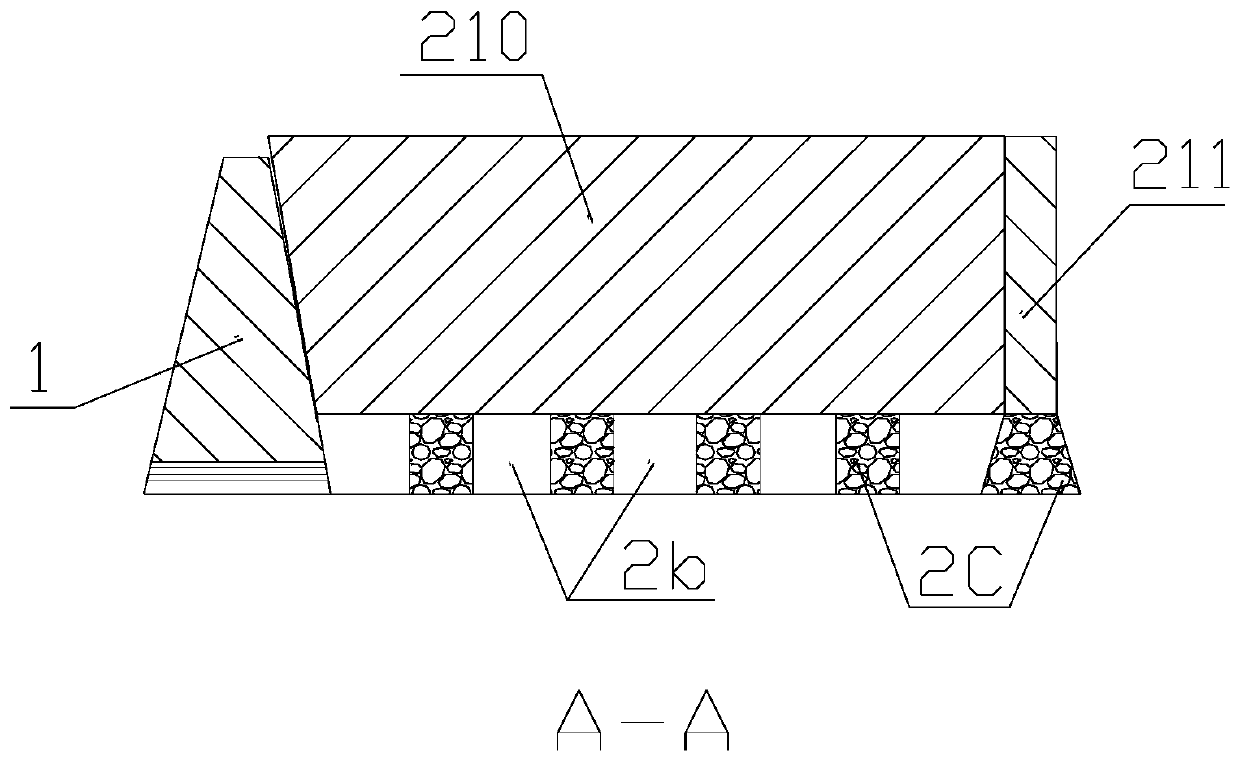

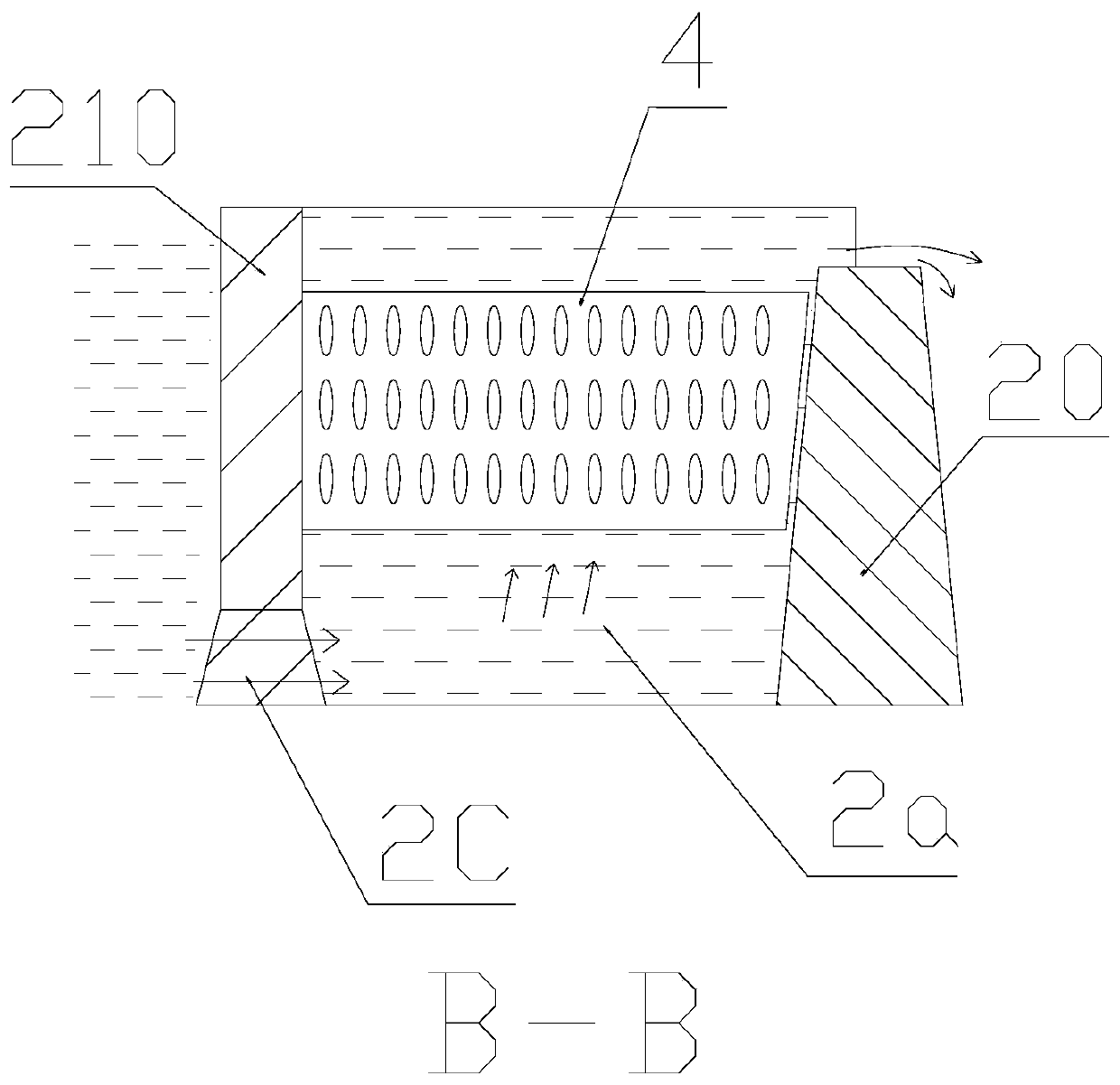

[0031] refer to Figure 1 to Figure 11 The shown water control engineering construction based on the modular filter layer of the present invention mainly includes the mainstream channel C, and the guide channel D or / and water collection structure arranged on the side of the mainstream channel C, and the guide channel D mainly plays the role of The drainage function is usually connected with the mainstream channel C, and the water collection structure mainly plays the role of storing clean water, and is usually relatively independent from the mainstream channel C. There is a barrage 1 for raising the water level in the mainstream channel C, and the main channel C A water purification plant 2 is provided. In this application, the water purification plant 2 is designed on the basis of the barrage 1 and the topographical conditions of the river bank, which can re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com