A two-way mixing method for making bottom-expanding powder-sprayed piles using alkali slag

A technology of two-way mixing and base powder expansion, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problems of poor integrity, poor economy, and high cost, so as to improve the integrity of the pile body, improve the overall bearing capacity, improve the The effect of end resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Level the site, put the two-way mixing pile driver in place, ensure that the shaft of the pile driver remains vertical, and the inclination of the drill pipe of the drilling rig is less than 1.0%;

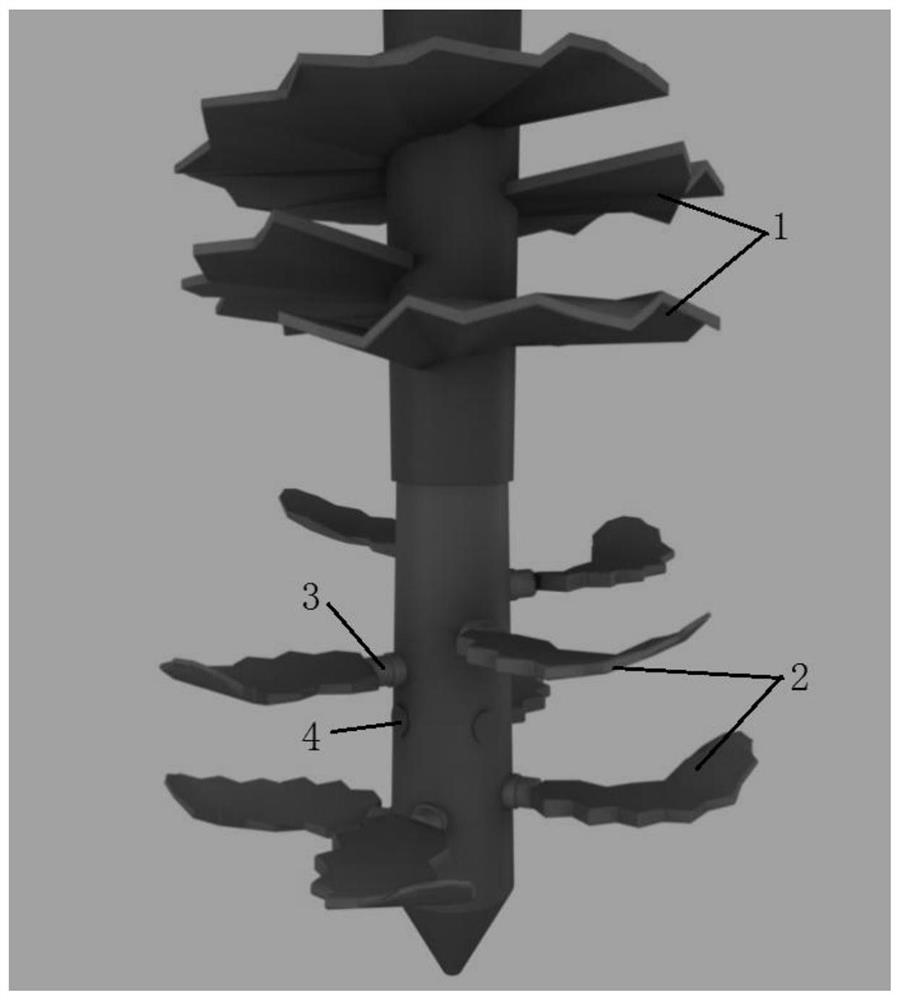

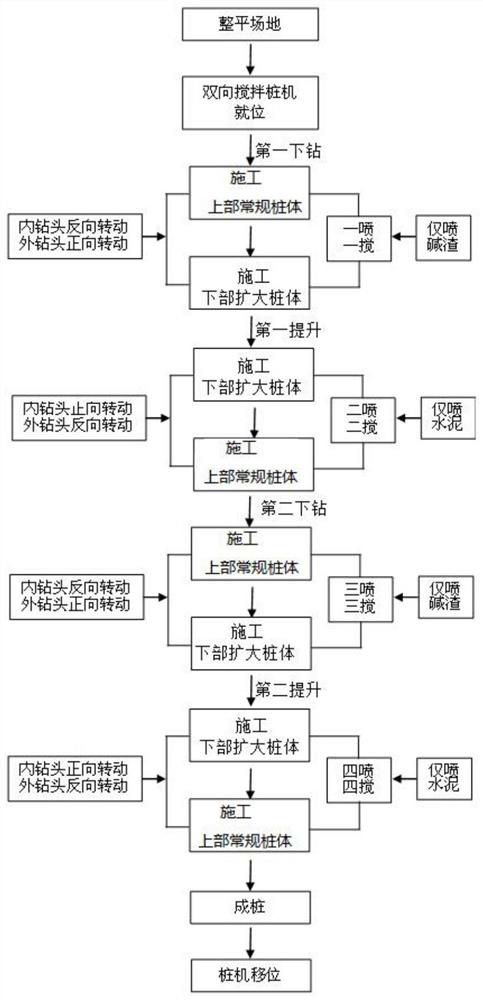

[0053] (2) Adjust the working radius of the stirring blade of the inner drill bit according to the diameter of the conventional pile body, control the connecting rod of the blade to shrink and rotate, and perform the first drilling (the drilling speed is 0.8m / min), the first ash spraying (alkali spraying) The amount of slag is 100kg / m) and the first stirring, construction conventional pile body, the diameter of the pile body is 500mm, after drilling to the top surface design elevation of the enlarged pile body; adjust the working radius of the inner drill bit stirring blade according to the diameter of the enlarged pile body, Control the extension of the connecting rod of the blade, continue the first drilling, the first ash spraying (the amount of alkali spraying slag is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com