Preparation method of lipid rich in sphingomyelin

A sphingomyelin and lipid technology, applied in the field of lipid preparation, can solve problems such as inability to be widely used in food, and achieve the effects of ensuring food safety and improving enrichment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] In a specific embodiment of the present invention, there is provided a method for preparing lipids rich in sphingomyelin, the preparation method comprising the following steps:

[0015] In order to solve the above-mentioned technical problems, the present invention provides a method for preparing sphingomyelin-rich lipids, the preparation method comprising the following steps:

[0016] Step 1): Heat the ethanol solution to 55°C to 80°C. After the temperature is stable, use a constant flow pump to inject the dairy products into the ethanol solution at a constant speed through a 1ml needle at a constant speed, wherein the concentration of the ethanol solution is 50%. ~80%, the volume ratio of dairy product to ethanol solution is 1:4~1:6, and the speed of the constant flow pump is 5rpm~15rpm.

[0017] Step 2): centrifuge the reaction product obtained in step 1) at a speed of 7500-9000 rpm / s in a centrifuge, and collect the supernatant;

[0018] Step 3): drying and concent...

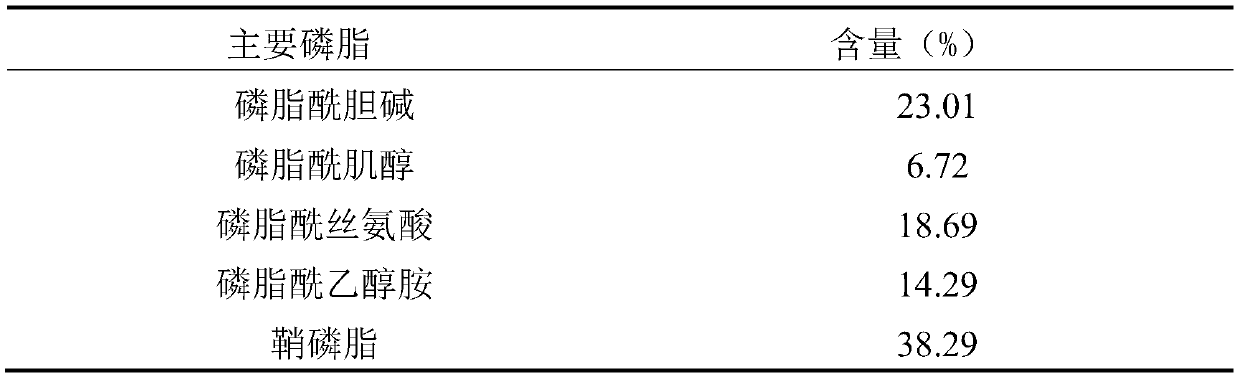

Embodiment 1

[0021] The method for preparing the lipid rich in sphingomyelin of embodiment 1 comprises the following steps:

[0022] Step 1): Heat the ethanol solution to 80°C. After the temperature is stable, use a constant flow pump to inject the skimmed milk powder solution through a 1ml needle into the ethanol solution at a constant speed at a constant speed, and react for 30 minutes. The concentration of the ethanol solution is 50 %, the volume ratio of skimmed milk powder solution to ethanol solution is 1:6, and the constant flow pump speed is 5rpm;

[0023] Step 2): centrifuge the reaction product obtained in step 1) at 7500rpm / s for 30min in a centrifuge, and collect the supernatant;

[0024] Step 3): Transfer the upper layer liquid collected in step 2) to a rotary evaporator, and evaporate to dryness at a water temperature of 55°C. After the upper layer liquid is evaporated to 1ml, collect the concentrated upper layer liquid; transfer the obtained concentrated upper layer liquid t...

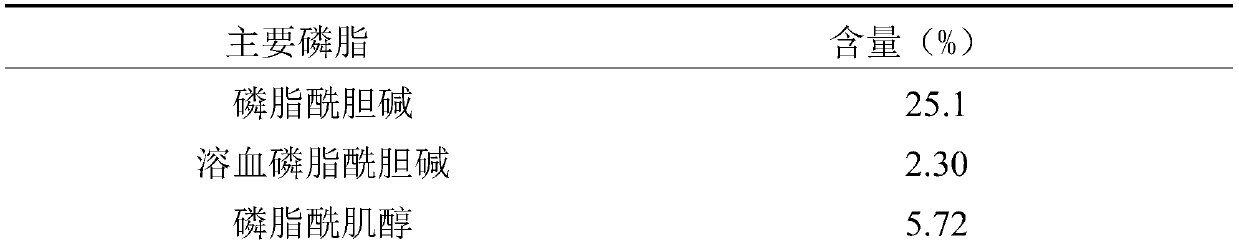

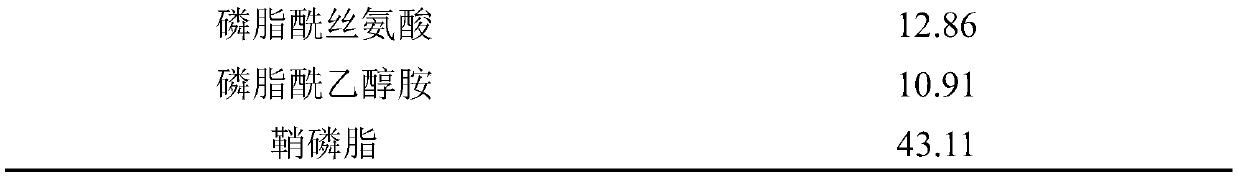

Embodiment 2

[0029] The method for preparing the lipid rich in sphingomyelin of embodiment 2 comprises the following steps:

[0030] Step 1): Heat the ethanol solution to 55° C., and after the temperature stabilizes, inject milk into the ethanol solution through a 1ml needle at a constant speed with a constant speed pump, and react for 30 minutes, wherein the concentration of the ethanol solution is 60%. The volume ratio of milk volume to ethanol solution is 1:4, and the constant flow pump speed is 15rpm;

[0031] Step 2): centrifuge the reaction product obtained in step 1) at a speed of 9000 rpm / s for 30 minutes in a centrifuge, and collect the supernatant;

[0032] Step 3): Transfer the upper layer liquid collected in step 2) to a rotary evaporator, and evaporate to dryness at a water temperature of 55°C. After the upper layer liquid is evaporated to 1ml, collect the concentrated upper layer liquid; transfer the obtained concentrated upper layer liquid to vacuum drying box, vacuum-dried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com