Pre-sulfurization method of fresh natural latex and latex product

A natural rubber latex and pre-vulcanization technology, which is applied in the field of natural rubber processing, can solve the problems of increasing the production cost and price of pre-vulcanized natural rubber latex, and cannot meet the production requirements of extruded products, etc., and achieve the effect of maintaining a stable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

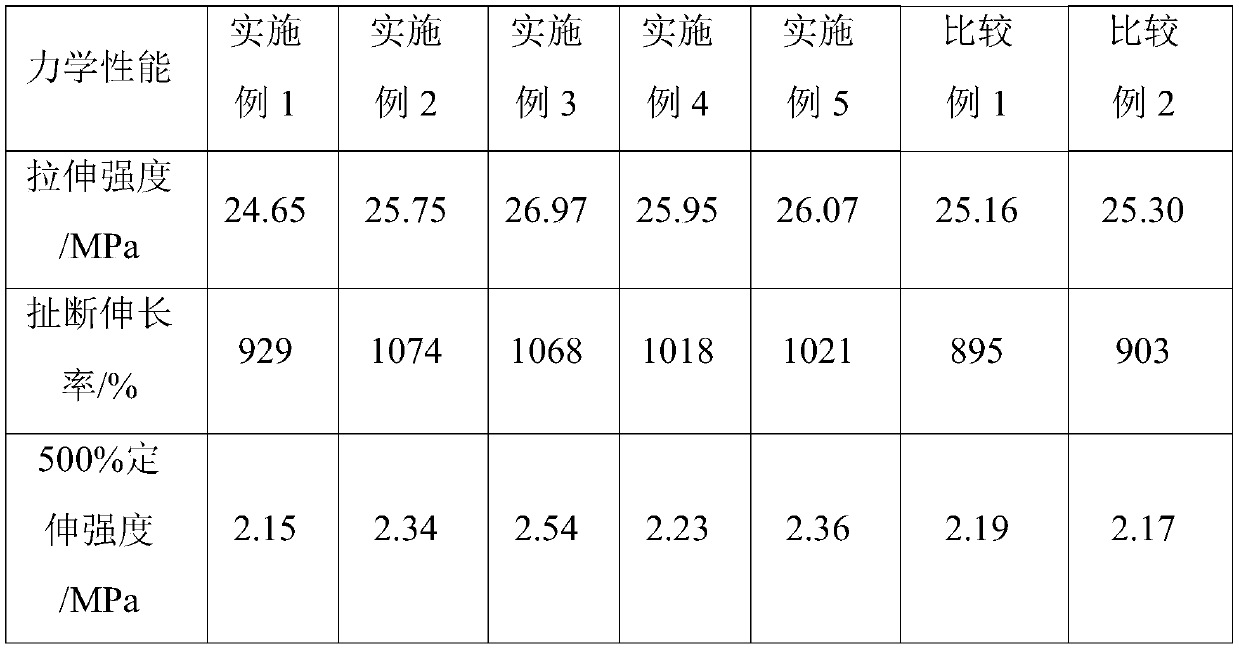

Embodiment 1

[0044] Take by weighing 37.5 parts of diallyl monosulfide, add water and be mixed with the emulsified solution that the mass fraction is 20%; Take by weighing 180 parts of the ammonia solution that the mass fraction is 25%; Take by weighing 7.5 parts of potassium hydroxide, be mixed with the mass fraction of 20% potassium hydroxide aqueous solution; weigh 7.5 parts of Pingping plus "O" to prepare a 20% Pingping plus "O" aqueous solution; weigh 60 parts of sulfur, grind and add water to prepare a 50% mass fraction of sulfur suspension ; Take by weighing 40 parts of zinc oxide, grind, add water and be mixed with mass fraction and be 50% zinc oxide suspension; Take by weighing 7.5 parts of phospholipids, be mixed with the aqueous solution that mass fraction is 20%; Weigh 190 parts of mass fraction and be 25% ammonia aqueous solution.

[0045] Weigh 15000 parts of fresh natural rubber latex (equivalent to 4500 parts by dry weight), add diallyl monosulfide emulsified solution and 1...

Embodiment 2

[0049] Take by weighing 75 parts of diallyl disulfide, add water and be mixed with the emulsification solution that the mass fraction is 20%; Take by weighing 180 parts of the ammonia solution that the mass fraction is 25%; Take by weighing 7.5 parts of potassium hydroxide, be mixed with the mass fraction of 20% potassium hydroxide aqueous solution; Weigh 7.5 parts of Pingping plus "O" to prepare a 20% Pingping plus "O" aqueous solution; Weigh 70 parts of sulfur, grind, add water to prepare a 50% mass fraction of sulfur suspension ; Take by weighing 43 parts of zinc oxide, grind, add water and be mixed with mass fraction and be 50% zinc oxide suspension; Take by weighing 7.5 parts of phospholipids, be mixed with the aqueous solution that mass fraction is 20%; Take by weighing 190 parts of mass fraction and be 25% ammonia aqueous solution.

[0050] Weigh 15000 parts of fresh natural rubber latex (equivalent to 4500 parts by dry weight), add diallyl disulfide emulsified solution...

Embodiment 3

[0054] Take by weighing 112.5 parts of diallyl disulfide, add water and be mixed with the emulsification solution that mass fraction is 20%; Take by weighing 180 parts of ammonia solution that the mass fraction is 25%; Take by weighing 7.5 parts of potassium hydroxide, be mixed with the mass fraction of 20% potassium hydroxide aqueous solution; Weigh 7.5 parts of Pingping plus "O" to prepare a 20% Pingping plus "O" aqueous solution; Weigh 80 parts of sulfur, grind, add water to prepare a 50% mass fraction of sulfur suspension ; Take by weighing 50 parts of zinc oxide, grind, add water and be mixed with mass fraction and be 50% zinc oxide suspension; Take by weighing 7.5 parts of phospholipids, be mixed with the aqueous solution that mass fraction is 20%; Take by weighing 190 parts of mass fraction and be 25% ammonia aqueous solution.

[0055] Weigh 15000 parts of fresh natural rubber latex (equivalent to 4500 parts by dry weight), add diallyl disulfide emulsified solution and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com