Addition-curable silicone composition, cured silicone and optical semiconductor device

A technology of optical semiconductor devices and silicone compositions, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as poor light transmission, achieve good crack resistance, excellent transparency and heat discoloration resistance, and hardness changes and weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0111] Hereinafter, the present invention will be specifically described using synthesis examples, examples, and comparative examples, but the present invention is not limited thereto.

[0112] In the following examples, the symbols indicating the composition of silicone oil or silicone resin are as follows.

[0113] M: (CH 3 ) 3 SiO 1 / 2

[0114] m Vi :(CH 2 =CH)(CH 3 ) 2 SiO 1 / 2

[0115] D. H :(CH 3 )HSiO 2 / 2

[0116] D:(CH 3 ) 2 SiO 2 / 2

[0117] D. Vi :(CH 2 =CH)(CH 3 ) SiO 2 / 2

Synthetic example 1

[0119] (D) Preparation of ingredients

[0120] 10 parts by mass (the amount of cerium is 0.55 parts) of turpentine oil solution (rare earth element content is 6 mass %) and 2.1 mass parts of n-butyl tetratitanate ( The mass of titanium is 0.3 times the mass of cerium in the 2-ethylhexanoate), and the mixture is fully stirred and added to 100 parts by mass of trimethylsiloxy-terminated trimethylsiloxy at both ends with a viscosity of 100 mPa·s. In dimethylpolysiloxane, a yellow-white dispersion liquid was obtained. A small amount of nitrogen gas was passed through it while heating to make the turpentine flow out, and then heated at 300° C. for 1 hour to obtain a thick reddish-brown transparent polyorganometallic siloxane.

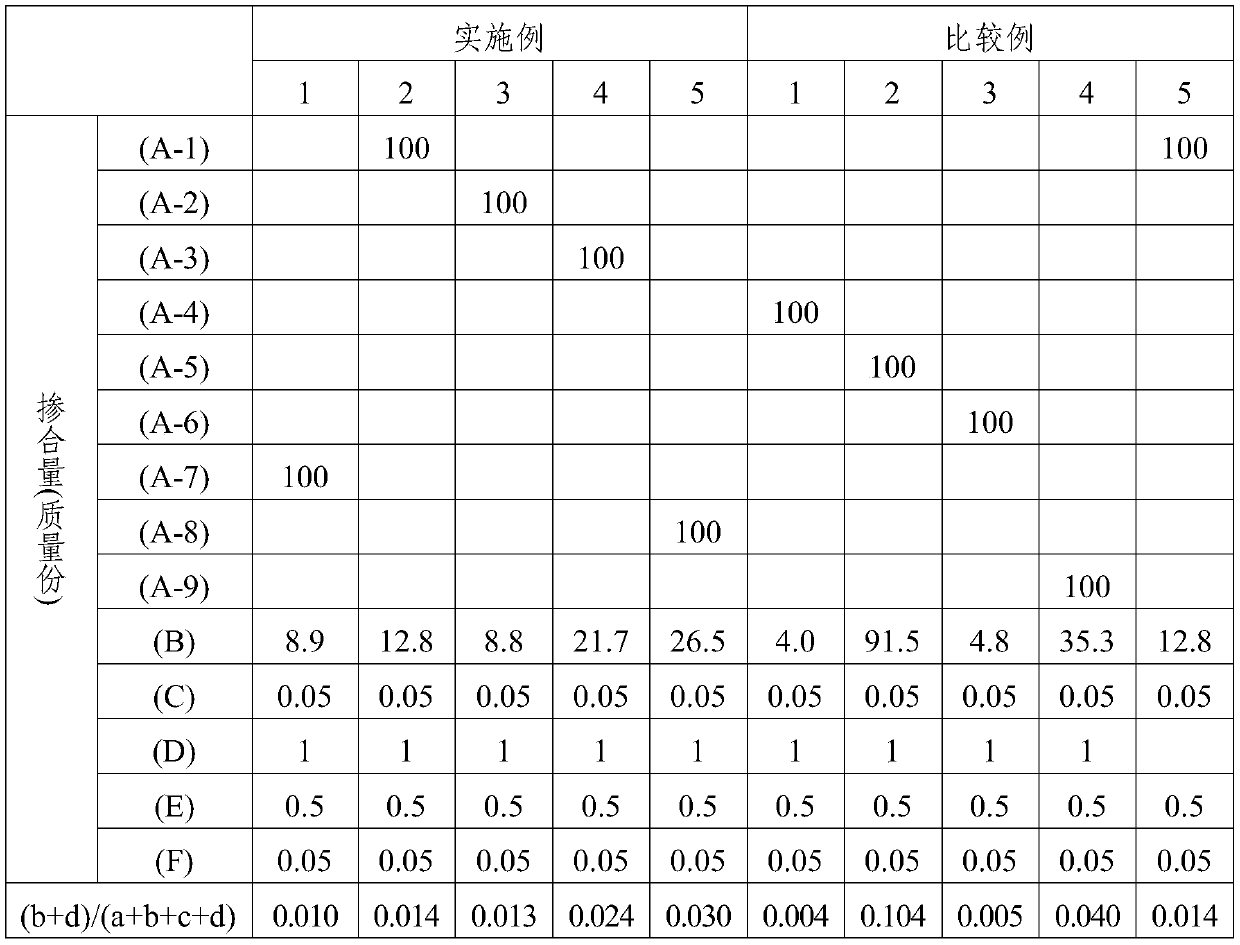

Embodiment 1~5、 comparative example 1~5

[0122] The following components were blended in the blending amounts (unit: parts by mass) shown in Table 1 to obtain an addition-curable silicone composition.

[0123] (A-1) Average composition formula M Vi 2 D. 445 D. Vi 4.5 (Vinyl: 0.19 mmol / g) organopolysiloxane with a viscosity of 5.0 Pa·s

[0124] (A-2) Average composition formula M 2 D. 550 D. Vi 5.5 Organopolysiloxane represented by (vinyl: 0.13 mmol / g) with a viscosity of 10.0 Pa·s

[0125] (A-3) Average composition formula M Vi 2 D. 440 D. Vi 9 (Vinyl: 0.33 mmol / g) organopolysiloxane with a viscosity of 5.0 Pa·s

[0126] (A-4) Average composition formula M Vi 2 D. 450 (Vinyl: 0.06 mmol / g) organopolysiloxane with a viscosity of 5.0 Pa·s

[0127] (A-5) Average composition formula M Vi 2 D. 405 D. Vi 45 Organopolysiloxane represented by (vinyl: 1.38 mmol / g) with a viscosity of 5.0 Pa·s

[0128] (A-6) Average composition formula M Vi 2 D. 550 D. Vi 1 (Vinyl: 0.07 mmol / g) organopolysiloxane wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com