Device and method for treating low-temperature methanol-washing hydrocarbon-containing exhaust gas

A low-temperature methanol washing and gas discharge technology, applied in the field of coal chemical industry, achieves the effect of realizing reuse, reducing equipment investment cost and operating cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

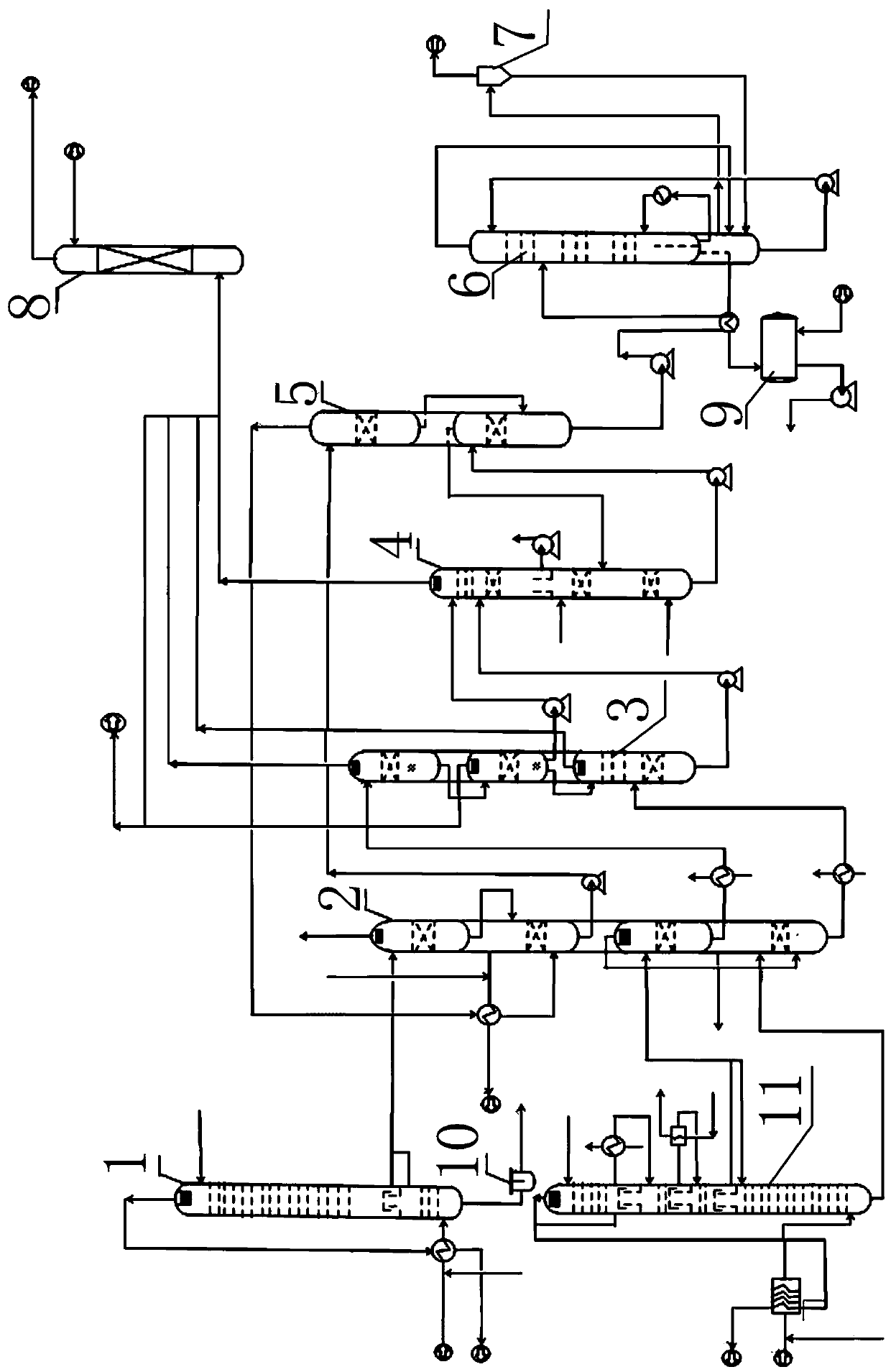

[0022] Such as figure 1 A device for treating low-temperature methanol washing hydrocarbon-containing exhaust gas is shown, including a coke oven gas absorption tower 1, a shift gas absorption tower 11, a flash tower 2, a carbon dioxide product tower 3, a hydrogen sulfide concentration tower 4, and a nitrogen stripping tower 5. Thermal regeneration tower 6, acid gas separator 7, tail gas washing tower 8, buffer tank 9; the flash tower 2 is divided into four sections from top to bottom, the upper two sections are coke oven gas treatment sections, and the lower two sections are The section is a shift gas treatment section; the lower drain pipe of the coke oven gas absorption tower 1 is connected to the upper coke oven gas treatment section of the flash tower 2, and the coke oven gas treatment section is connected to the nitrogen stripping tower 5; the shift gas absorption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com