Electric-magnetic field synergetic enhancement high-power pulse magnetron sputtering deposition device and method

A high-power pulse, magnetron sputtering technology, applied in the field of coating, can solve the problems of low electron utilization rate and deposition rate ion ionization rate, and achieve the effect of improving electron utilization efficiency, increasing deposition rate and realizing simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

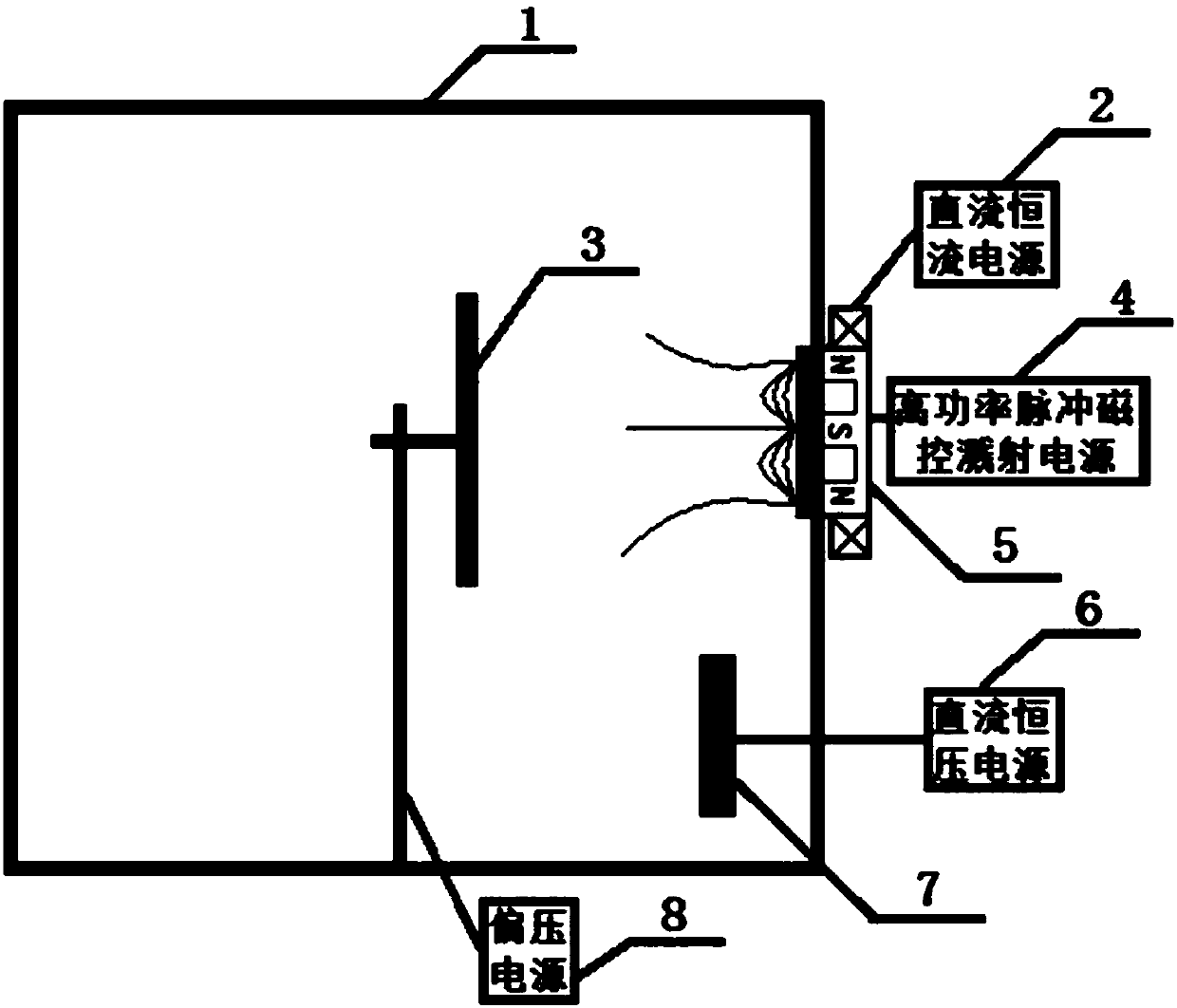

[0023] Specific implementation mode one: combine figure 1 Describe this embodiment, the electric-magnetic field synergistically enhanced high-power pulse magnetron sputtering deposition device described in this embodiment, the deposition device includes a vacuum chamber 1, a workpiece frame 3, a high-power pulse magnetron sputtering power supply 4, a cathode Magnetron target 5 and bias power supply 8; Bias power supply 8 provides bias voltage for workpiece holder 3 in vacuum chamber 1, and high-power pulse magnetron sputtering power supply 4 supplies power for cathode magnetron target 5, and the cathode magnetron target 5 provides a permanent magnetic field for the vacuum chamber 1;

[0024] It is characterized in that the deposition device also includes a DC constant current power supply 2, a DC constant voltage power supply 6, an auxiliary anode 7 and an excitation coil; the excitation coil is wound on the outside of the cathode magnetron target 5, and the DC constant curren...

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment is the deposition method of the electric-magnetic field synergistically enhanced high-power pulse magnetron sputtering deposition device described in Embodiment 1. The deposition method includes the following steps:

[0026] Step 1 and Step 2 are performed separately, and then Step 3 is performed:

[0027] Step 1: Build electric field enhanced high power pulsed magnetron discharge:

[0028] The high-power pulse magnetron sputtering power supply 4 and the bias power supply 8 work. By adjusting the position of the auxiliary anode in the vacuum chamber 1 and controlling the output voltage of the DC constant voltage power supply 6, the trajectory of the electrons is changed so that the electrons reach the deposition area. Thereby determine the magnitude of the voltage output by the DC constant voltage power supply 6 and the position of the auxiliary anode in the vacuum chamber 1;

[0029] In this step, when the high-power pulse magnetron sputt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com