A mim waveguide structure based on hybrid high quality factor

A waveguide structure, high-quality technology, applied in light guides, instruments, optics, etc., can solve problems such as Q factor instability, achieve stable Q factor, high sensitivity, and improve Q factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

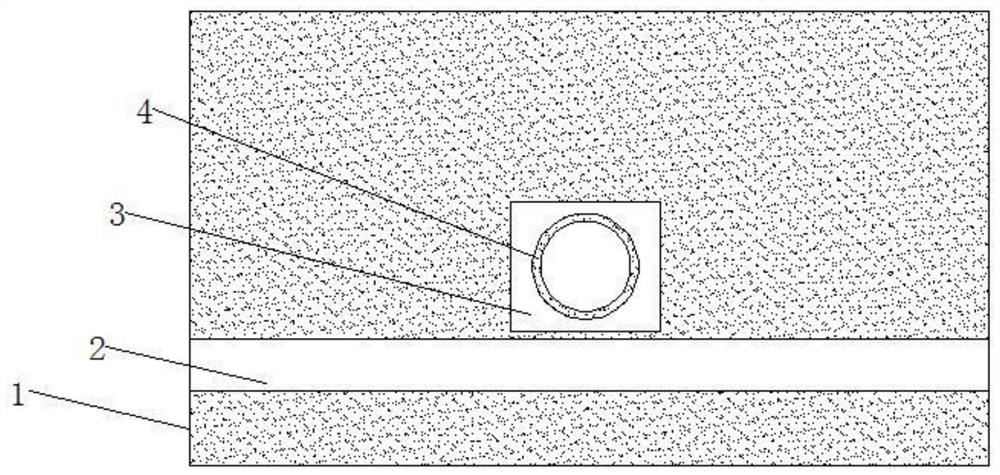

[0029] In order to solve the defect that the Q factor is unstable when the optical waveguide device of the existing waveguide optical system performs waveguide coupling. This embodiment provides a figure 1 The MIM waveguide structure based on the hybrid high quality factor shown includes a main body 1, an optical channel 2 is arranged above the main body 1; a first resonant cavity 3 is arranged above the optical channel 2; the first resonant A first resonant ring 4 is set in the cavity 3; when light enters the optical channel 2 from the entrance at the left end, surface plasmons will be excited in the optical channel 2, and are connected with the first resonant cavity 3 above, the first The resonant ring 4 is coupled, and the first resonant cavity 3 and the first resonant ring 4 each generate different plasmon resonances, and the different plasmon resonances are combined to form a hybrid plasmon resonance, so that the The MIM waveguide structure has a high Q factor, and the M...

Embodiment 2

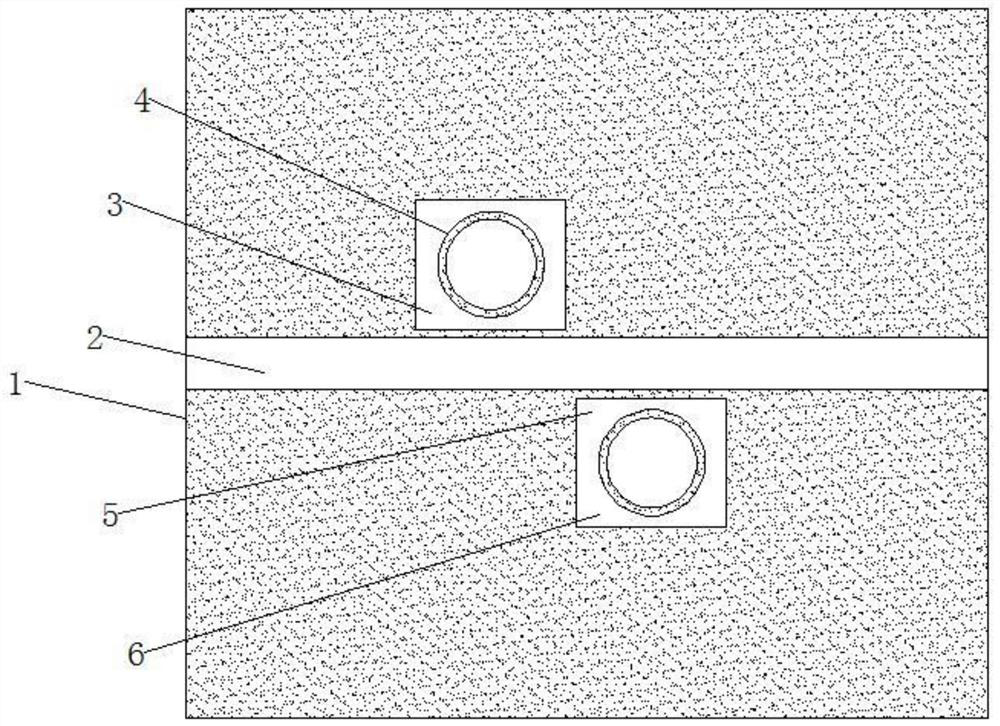

[0036] The embodiment provides a method such as figure 2 The MIM waveguide structure based on the hybrid high quality factor shown includes a main body 1, an optical channel 2 is arranged above the main body 1; a first resonant cavity 3 is arranged above the optical channel 2; the first resonant A first resonant ring 4 is provided in the cavity 3; a second resonant cavity 5 is provided below the optical channel 2; a second resonant ring 6 is provided in the second resonant cavity 5; the first resonant ring 4 and The axes of the second resonant ring 6 are parallel. When the light enters the optical channel 2 from the entrance at the left end, the surface plasmons will be excited in the optical channel 2, and will interact with the first resonant cavity 3 above, the first resonant ring 4, and the second resonant cavity 5 above. , the second resonant ring 6 are coupled, and the first resonant cavity 3, the first resonant ring 4, the second resonant cavity 5, and the second reso...

Embodiment 3

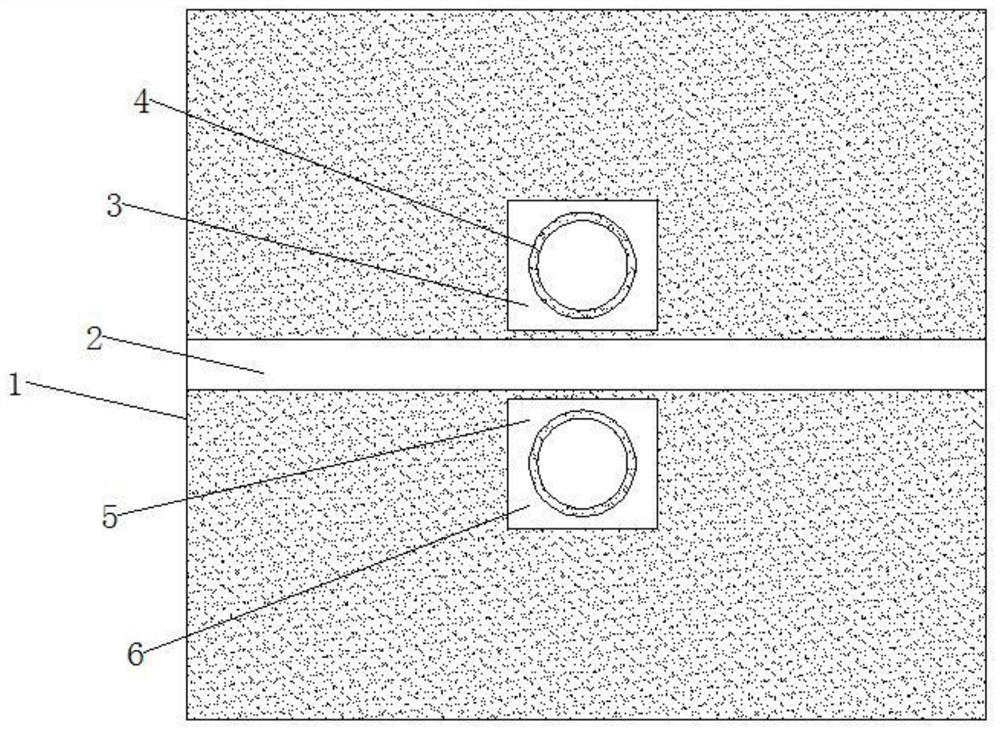

[0040] On the basis of Example 2, such as image 3 As shown, the first resonant cavity 3 and the second resonant cavity 5 are asymmetrically arranged with the optical channel 2 as an asymmetrical axis, the resonance modes of the two resonant cavities are superimposed on each other, and the phase is adjusted by the distance to form a more complex Fano resonance, which has a good effect on refraction rate changes are more sensitive; if Figure 7 Shown is the transmission spectrum of the MIM waveguide structure based on the hybrid high quality factor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com