Turret-type die bonder

A crystal-bonding machine and turret-type technology, which is applied in the direction of conveyor objects, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of high price, restricting the development of small and medium-sized enterprises, repeated positioning material rate and reliability to be improved, etc. , to achieve the effect of high reliability manufacturing process requirements and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

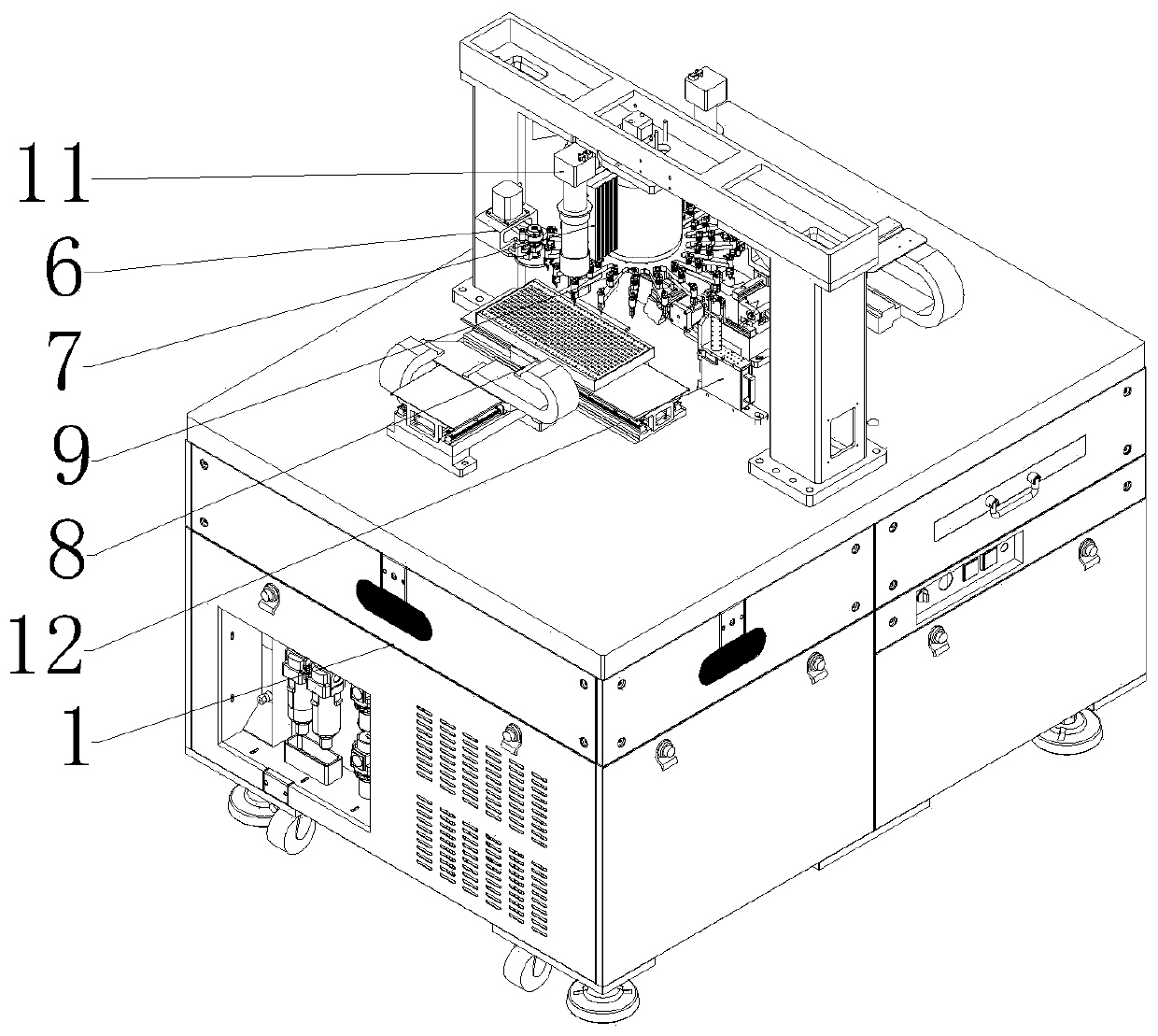

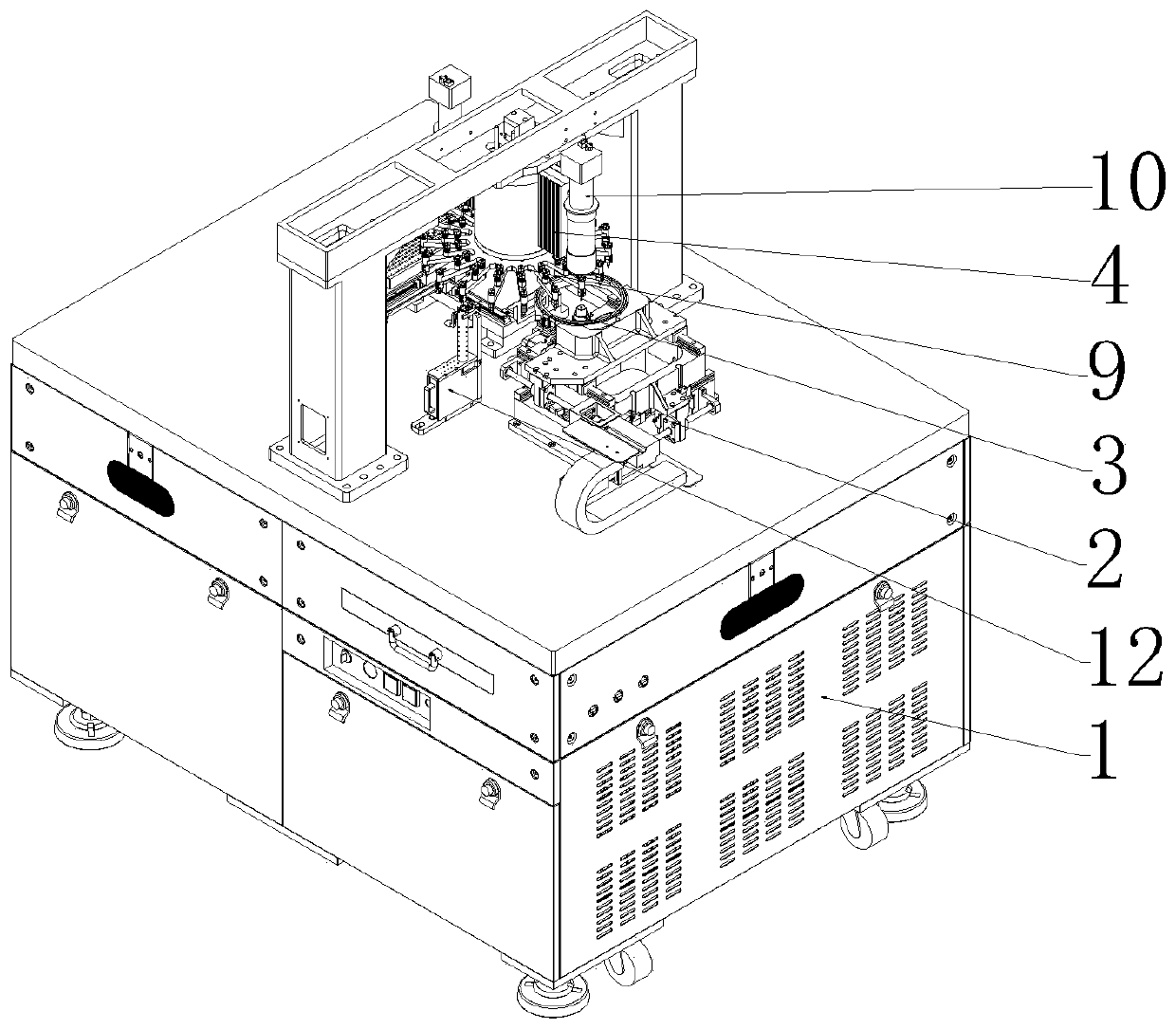

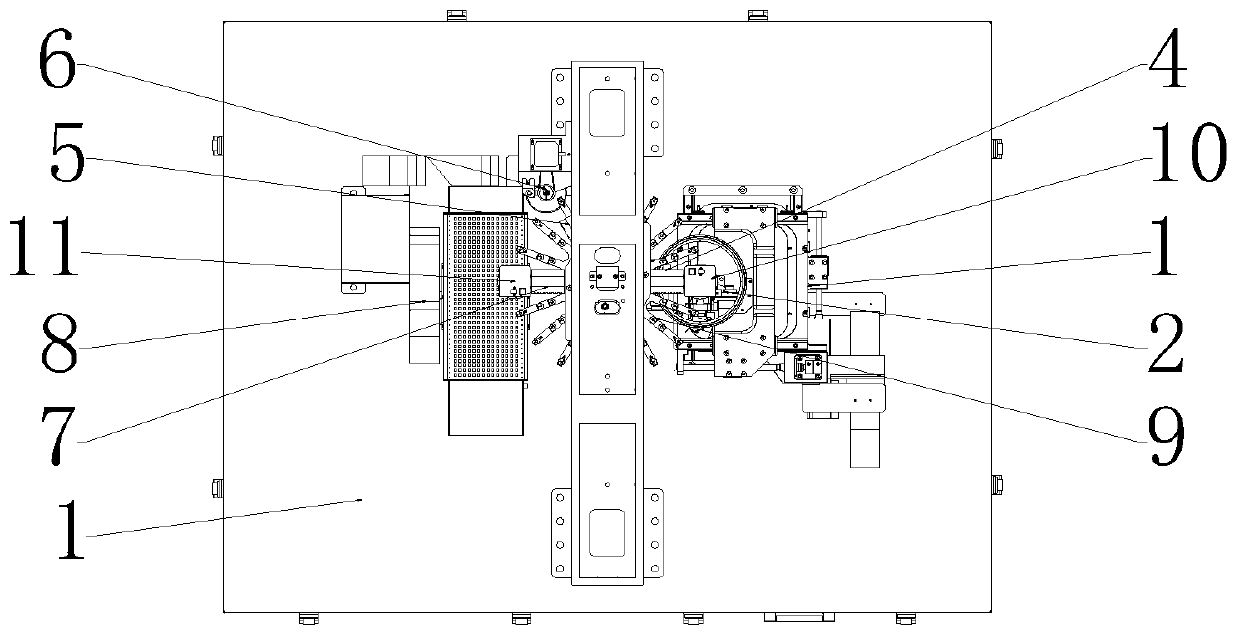

[0045] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific embodiments.

[0046]As an embodiment, the present invention proposes a turret-type crystal bonding machine, including a correction compensation system, a crystal extraction system, a glue dispensing system, a crystal bonding system, a turret system, and a detection system;

[0047] Wherein, the correction compensation system is used for fine-tuning the position of the chip on the wafer on which the chip is loaded;

[0048] The crystal picking system is used to pick up the chips on the wafer;

[0049] The glue dispensing system is used to dispens glue on the lead frame where the chip is placed after the crystal is taken;

[0050] The crystal-bonding system is used for performing a crystal-bonding operation on the chip on the lead frame after dispensing;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com