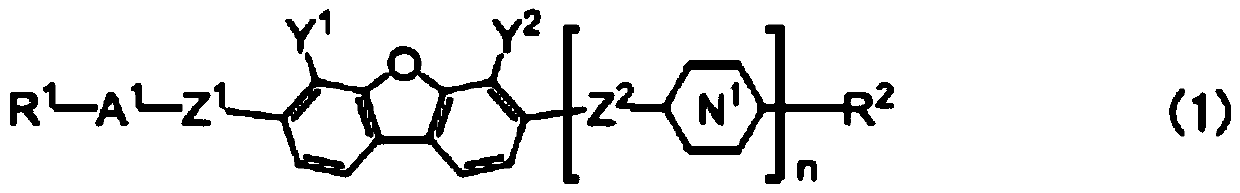

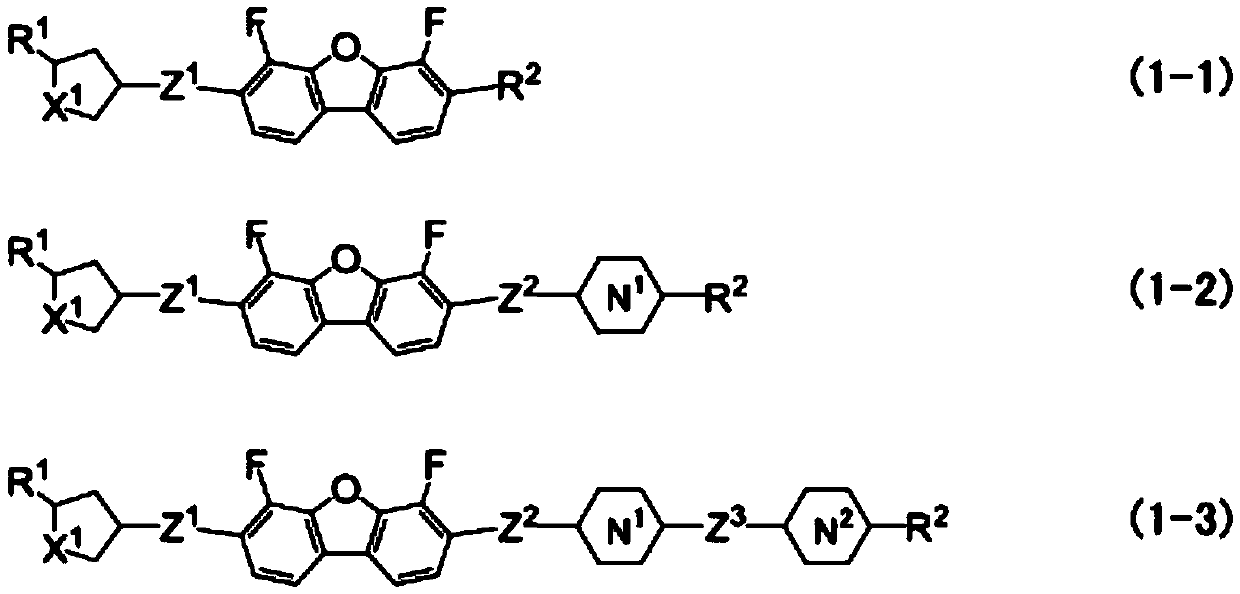

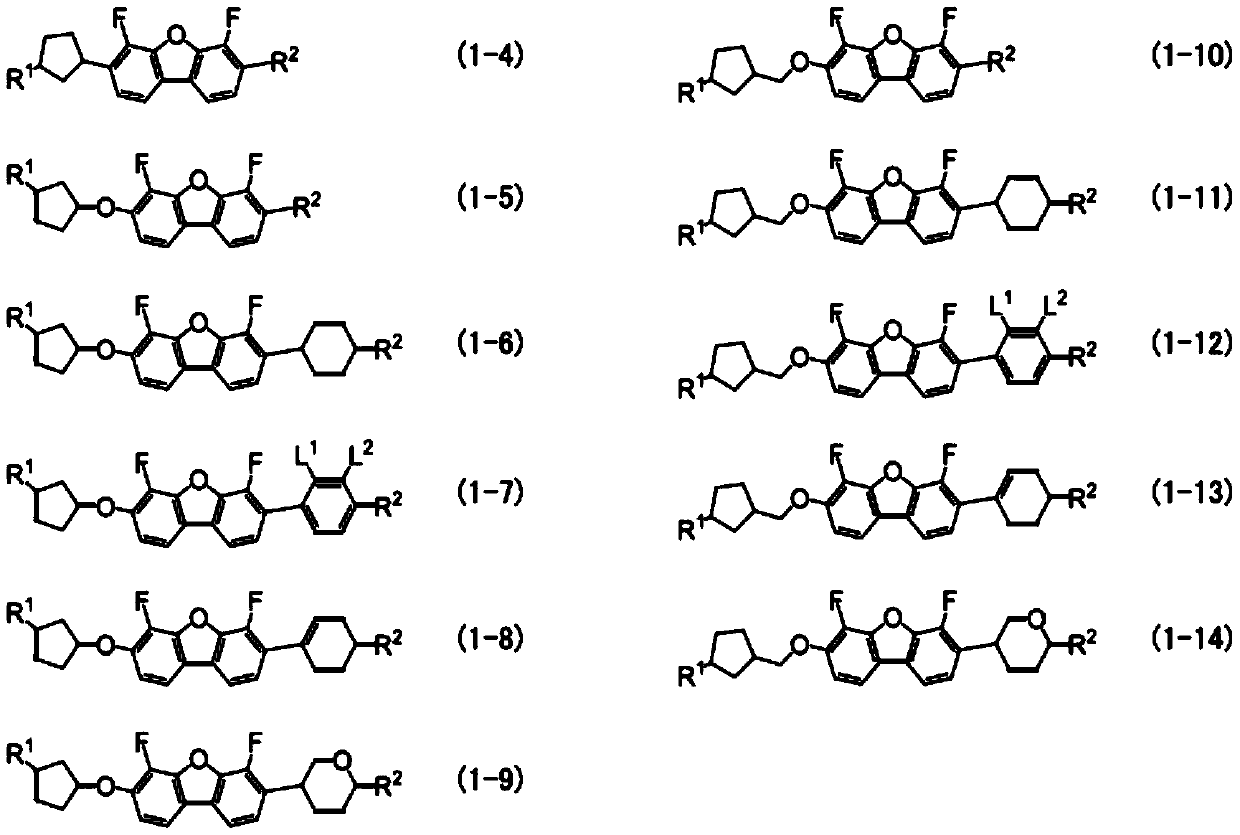

Compound having dibenzofuran ring, liquid crystal composition, and liquid crystal display element

A compound and group technology, used in organic chemistry, liquid crystal materials, chemical instruments and methods, etc., can solve problems such as insufficient compatibility, and achieve the effects of short response time, wide temperature range, and low threshold voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0245] 1. Examples of compound (1)

[0246] The present invention is illustrated in more detail by way of examples. The Examples are typical examples, and therefore the present invention is not limited by the Examples. Compound (1) was synthesized by the following procedure. The synthesized compound was identified by nuclear magnetic resonance (Nuclear Magnetic Resonance, NMR) analysis and other methods. The physical properties of the compound or composition, and the characteristics of the device were measured by the following methods.

[0247] NMR analysis: DRX-500 manufactured by Bruker BioSpin was used for measurement. exist 1 In the measurement of H-NMR, the sample is dissolved in CDCl 3 and other deuterated solvents, and measured at room temperature, 500 MHz, and accumulated times 16 times. Tetramethylsilane was used as an internal standard. exist 19 In the determination of F-NMR, the CFCl 3 It was used as an internal standard, and it carried out by accumulating ...

Synthetic example 1

[0286] Synthesis of Compound (No.26)

[0287]

[0288] Step 1: Synthesis of compound (T-2)

[0289] Under nitrogen atmosphere, compound (T-1) (16.0g), cyclopentylmethanol (8.39g), triphenylphosphine (26.4g), and tetrahydrofuran (Tetrahydrofuran, THF) (150mL) are put into reactor , cooled on an ice bath. Diethyl azodicarboxylate (DEAD (azodicarboxylic acid diethyl), 2.2M; toluene solution; 45.7 ml) was added, and stirred at room temperature for 8 hours. After the reaction, the reaction mixture was poured into water, and the water layer was extracted with toluene. The combined organic layers were washed with brine, dried over anhydrous magnesium sulfate, and concentrated under reduced pressure. Compound (T-2) (19.8 g; 86%) was obtained by purifying the residue by silica gel chromatography (volume ratio, toluene:heptane=1:4).

[0290] Step 2: Synthesis of compound (T-3)

[0291]Under a nitrogen atmosphere, compound (T-2) (19.8 g) and tetrahydrofuran (THF, 200 mL) were put...

Synthetic example 2

[0299] Synthesis of compound (No.3)

[0300]

[0301] Step 1: Synthesis of compound (T-7)

[0302] Under a nitrogen atmosphere, compound (T-6) (60.0 g) and tetrahydrofuran (500 ml) were put into a reactor, and cooled to -70°C. Thereto, n-butyl lithium (1.64M; n-hexane solution; 127.7 ml) was slowly added, followed by stirring for 1 hour. Then, a solution of cyclopentanone (17.6 g) in tetrahydrofuran (50.0 ml) was slowly added, and the mixture was returned to room temperature and stirred for 12 hours. The reaction mixture was poured into water, and the aqueous layer was extracted with toluene. The mixed organic layers were washed with brine, and dried over anhydrous magnesium sulfate. The solution was concentrated under reduced pressure, and purified by silica gel chromatography (volume ratio, ethyl acetate:heptane=1:8), thereby obtaining Compound (T-7) (31.9 g; 57%).

[0303] Step 2: Synthesis of compound (T-8)

[0304] Under a nitrogen atmosphere, compound (T-7) (31.9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com