Contact type liquid nitrogen cryotherapy device

A technology of liquid nitrogen freezing and treatment equipment, applied in the field of skin disease treatment and beauty, can solve the problems of unclear freezing temperature, hypoxia and suffocation of patients, and the temperature that cannot reach liquid nitrogen, so as to avoid the battle between doctors and patients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

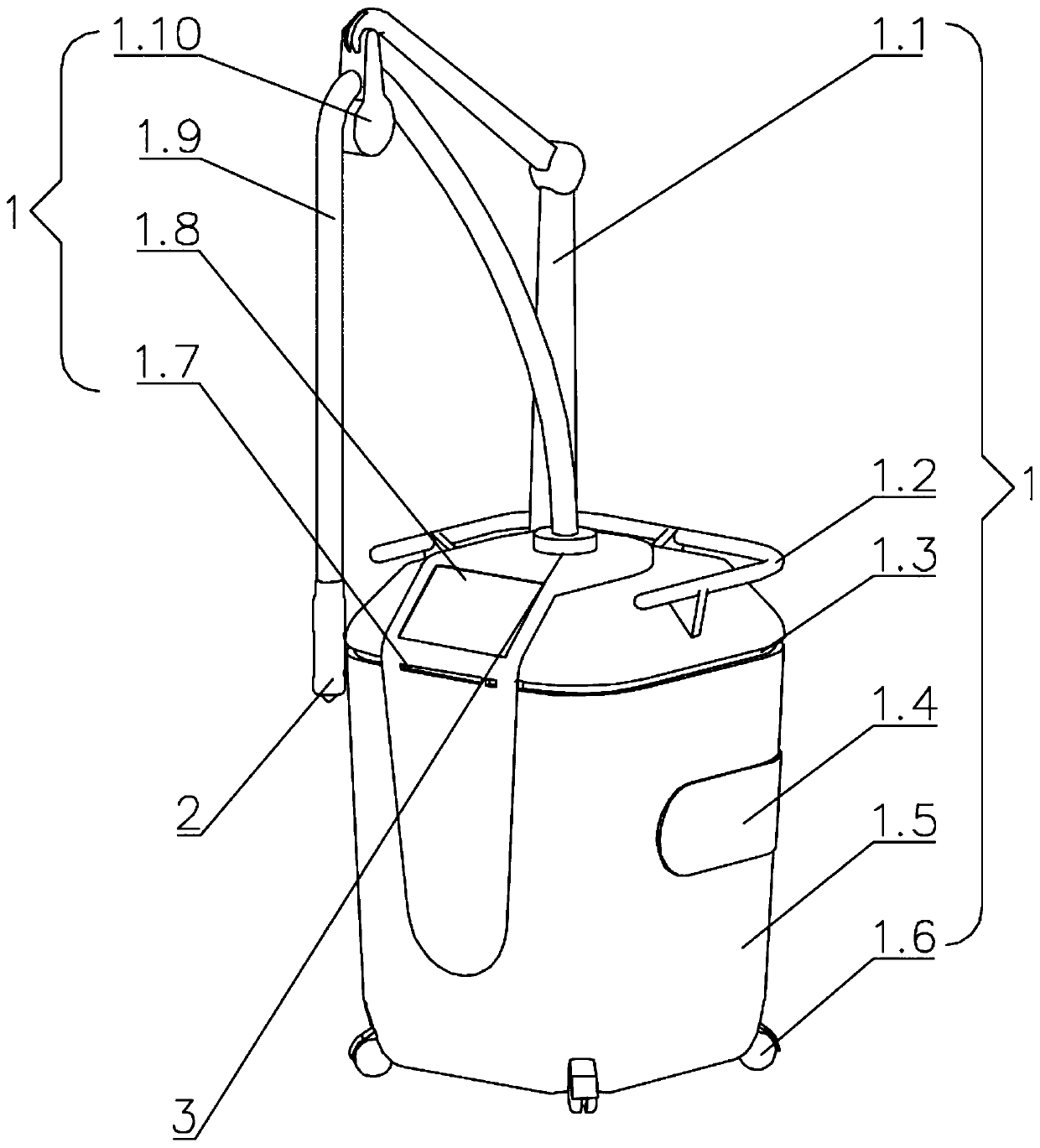

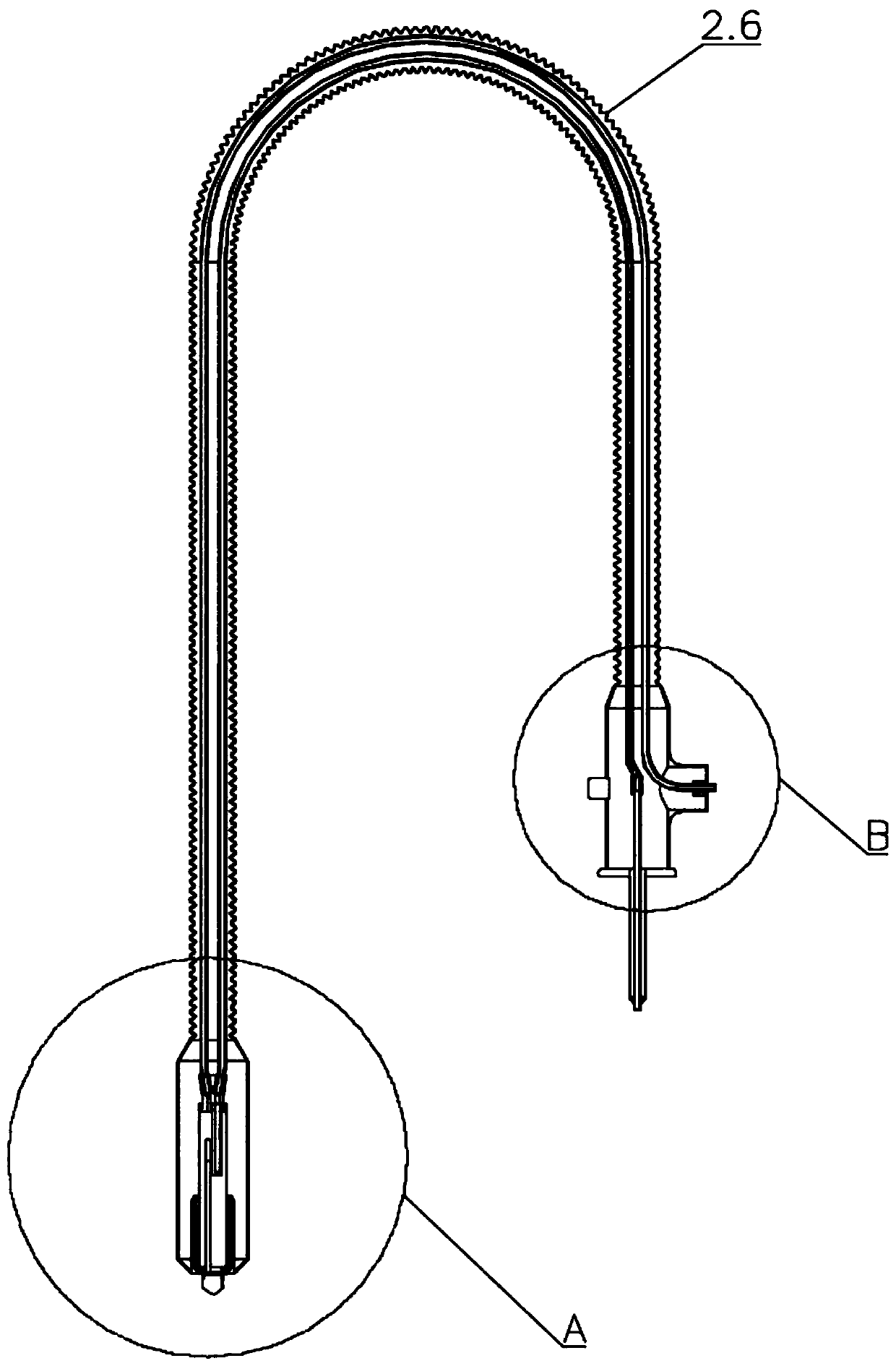

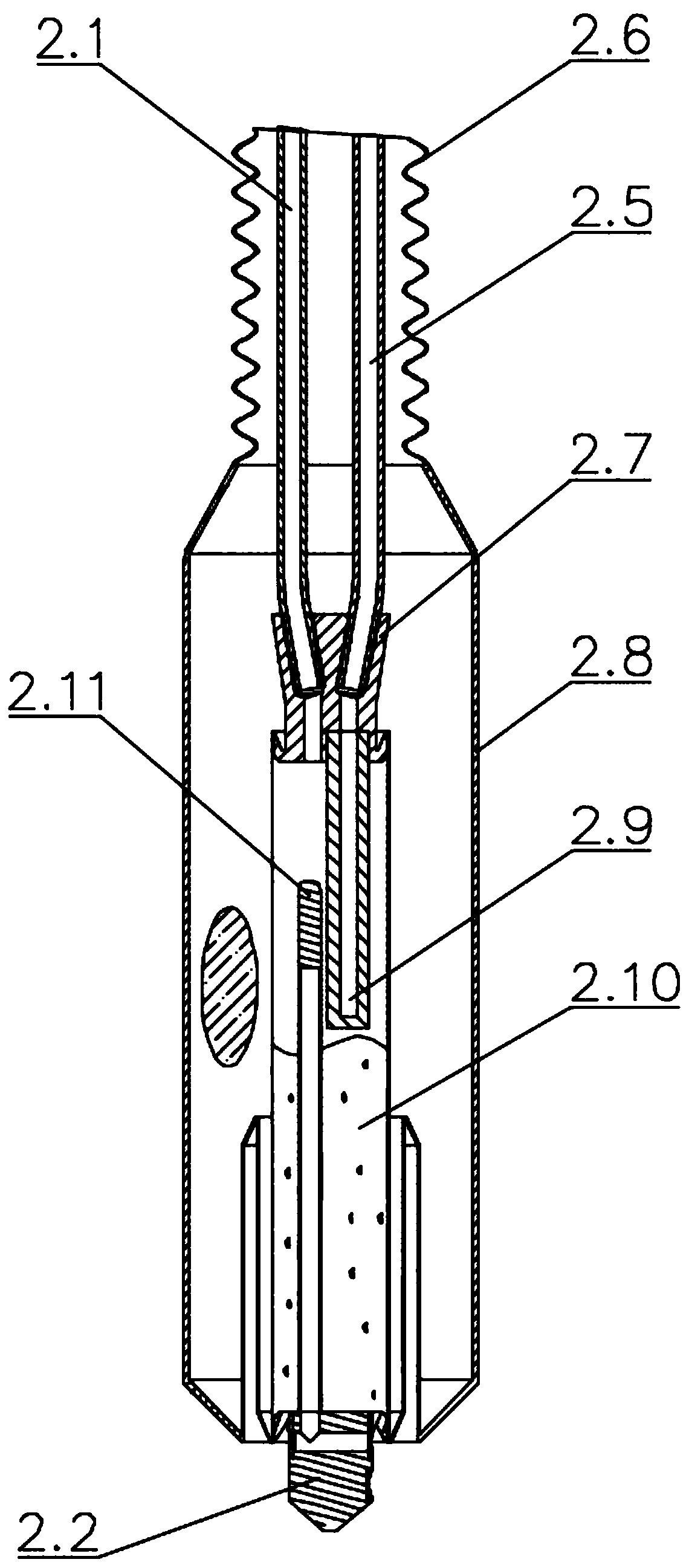

[0037] As shown in the figure, a contact type liquid nitrogen cryotherapy equipment includes an outer layer mechanism 1, an implementing mechanism 2, and an inner layer mechanism 3. The outer layer mechanism 1 is arranged outside the inner layer mechanism 3, and the implementing mechanism 2 is connected with the inner mechanism 3; the implementing mechanism 2 includes a gas phase tube 2.1, a frozen head 2.2, a vacuum male joint 2.3, a ferrule flange 2.4, a liquid phase tube 2.5, a stainless steel thin-walled tube 2.6, an inner tube seat 2.7, and an outer shell 2.8, phase separator 2.9, liquid effusion device 2.10, temperature probe 2.11, transition tube 2.12, vacuum interface 2.13, tee shell 2.14, the ends of the gas phase tube 2.1 and liquid phase tube 2.5 are inserted in the upper part of the shell 2.8, the The gas phase tube 2.1 and the liquid phase tube 2.5 are arranged in the stainless steel thin-walled tube 2.6, the end of the gas phase tube 2.1 and the end of the liquid ...

Embodiment 2

[0041] As shown in the figure, the ends of the liquid phase tube 2.5 and the gas phase tube 2.1 are processed with a section of external thread by a die, and the surface of the thread is coated with low-temperature glue and screwed into the internal thread of the inner pipe seat 2.7 made of stainless steel. Low-temperature glue is used for sealing; the bottom liquid nitrogen outlet of the inner pipe seat 2.7 is connected to the phase separator 2.9, and the liquid nitrogen injected through the liquid phase pipe 2.5 passes through the dense micropores in the phase separator 2.9. Nitrogen naturally gathers downwards in the lower half of the liquid accumulator 2.10, and the nitrogen is transported upward by the gas phase pipe 2.1 and discharged to the outside of the liquid nitrogen container 3.6 through the exhaust port 1.4; the temperature probe 2.11 is installed on the frozen head 2.2, and the probe It is located in the upper part of the liquid accumulator 2.10; the liquid nitrog...

Embodiment 3

[0043] As shown in the figure, the liquid nitrogen container 3.6 with high-vacuum multi-layer insulation is used to store liquid nitrogen, and the liquid nitrogen in the liquid nitrogen container 3.6 measures the pressure through the pressure sensor 3.8 and feeds the measured data back to the touch screen controller 1.8 , the controller judges the start / stop of the heater 3.11 according to the comparison between the measured value and the set value, the liquid nitrogen is vaporized by the heater 3.11 to increase the pressure in the container, and the pressure heater 3.11 does not start when the required pressure is reached, and the pressure exceeds When high, the safety valve 3.4 is opened to release the pressure; the pressure gauge 3.3 is mechanically used for pressure display when the power supply is not turned on, and the capacitance liquid level gauge 3.9 measures the height of the liquid nitrogen liquid level in the container. When the liquid level height is low When setti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com