A control device for changing the position of the stagnation point of the flow field and its use

A control device and stagnation point technology, applied in streamlined body, transportation and packaging, aerodynamic improvement, etc., can solve the problems of increased resistance, increased surface resistance of the car, and damage to the aerodynamic shape, etc., to achieve good sealing and electromagnetic driving force Large, responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

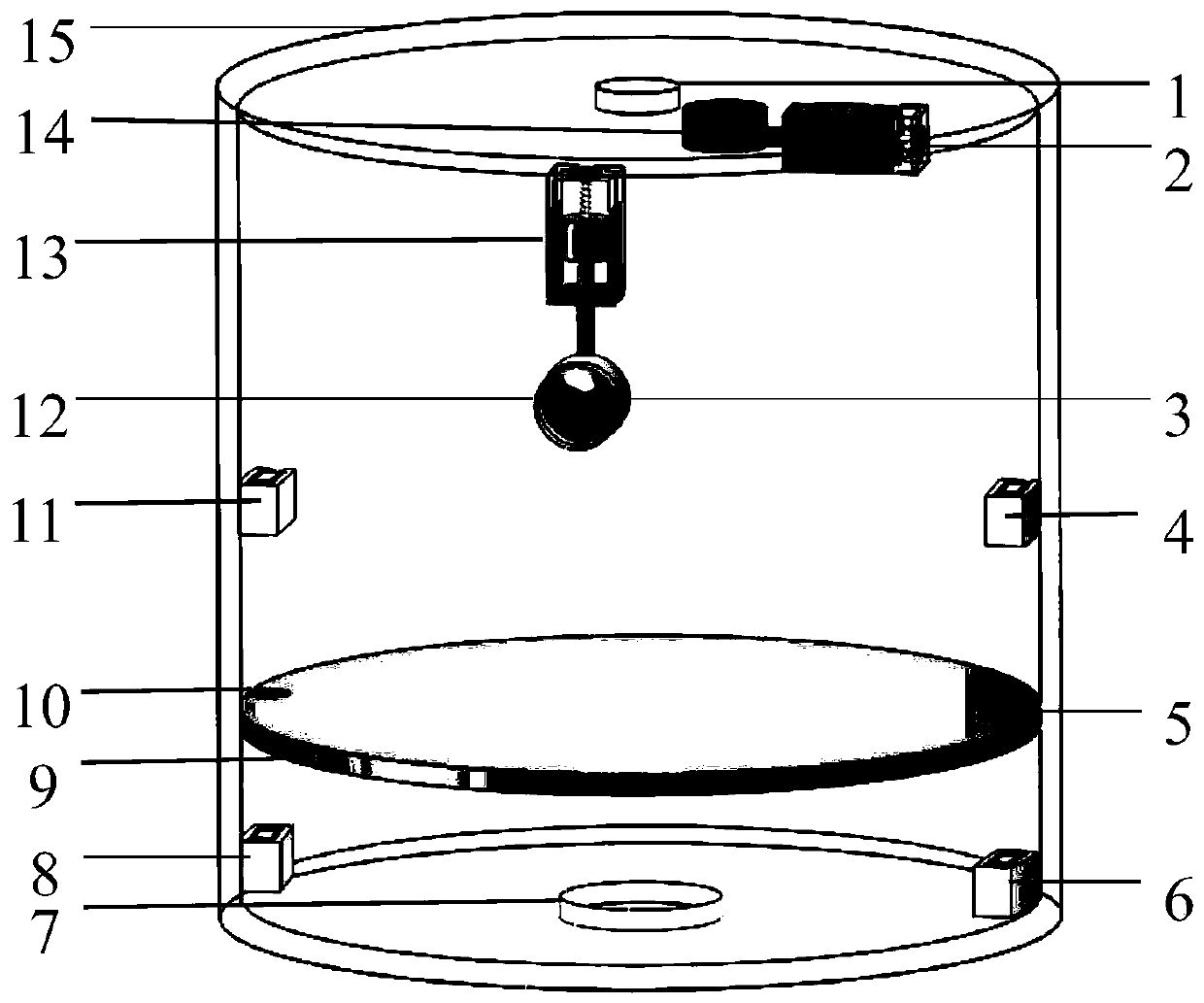

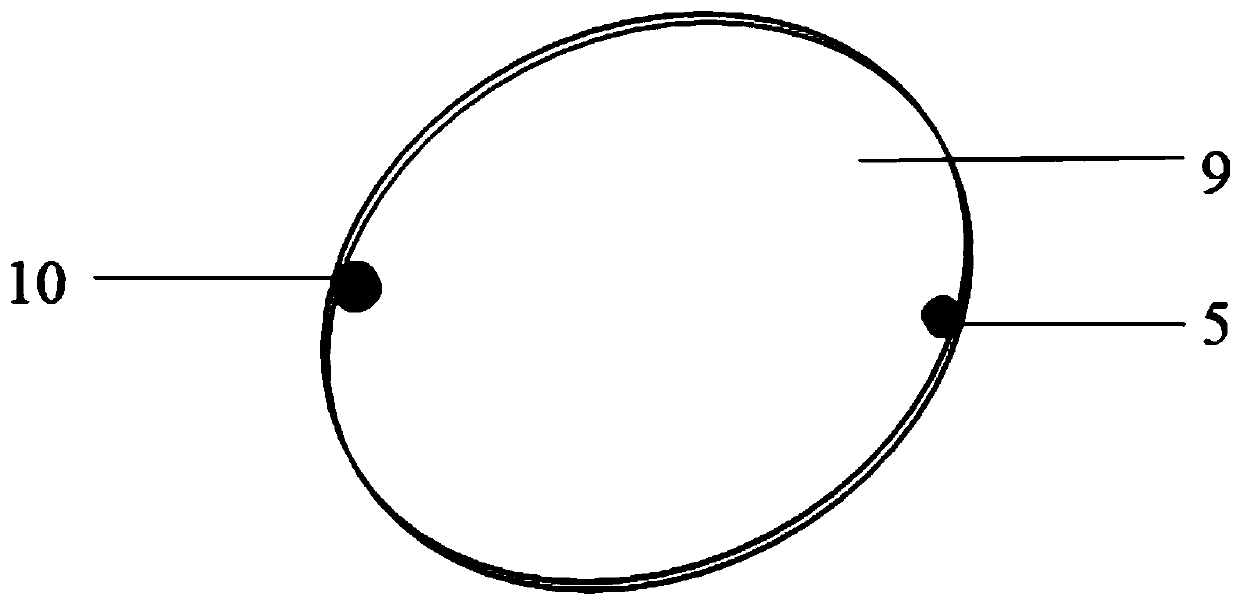

[0020] Such as figure 1 As shown, it is a structural schematic diagram of a control device for changing the stagnation point position of the flow field according to the present invention. The control device mainly includes: a first proportional electromagnet 2, a second plug 3, a first electromagnet A 4, Armature A 5, second electromagnet A6, second electromagnet B 8, rubber piston 9, armature B 10, second electromagnet B 11, second proportional electromagnet 13, first plug 14, housing 15.

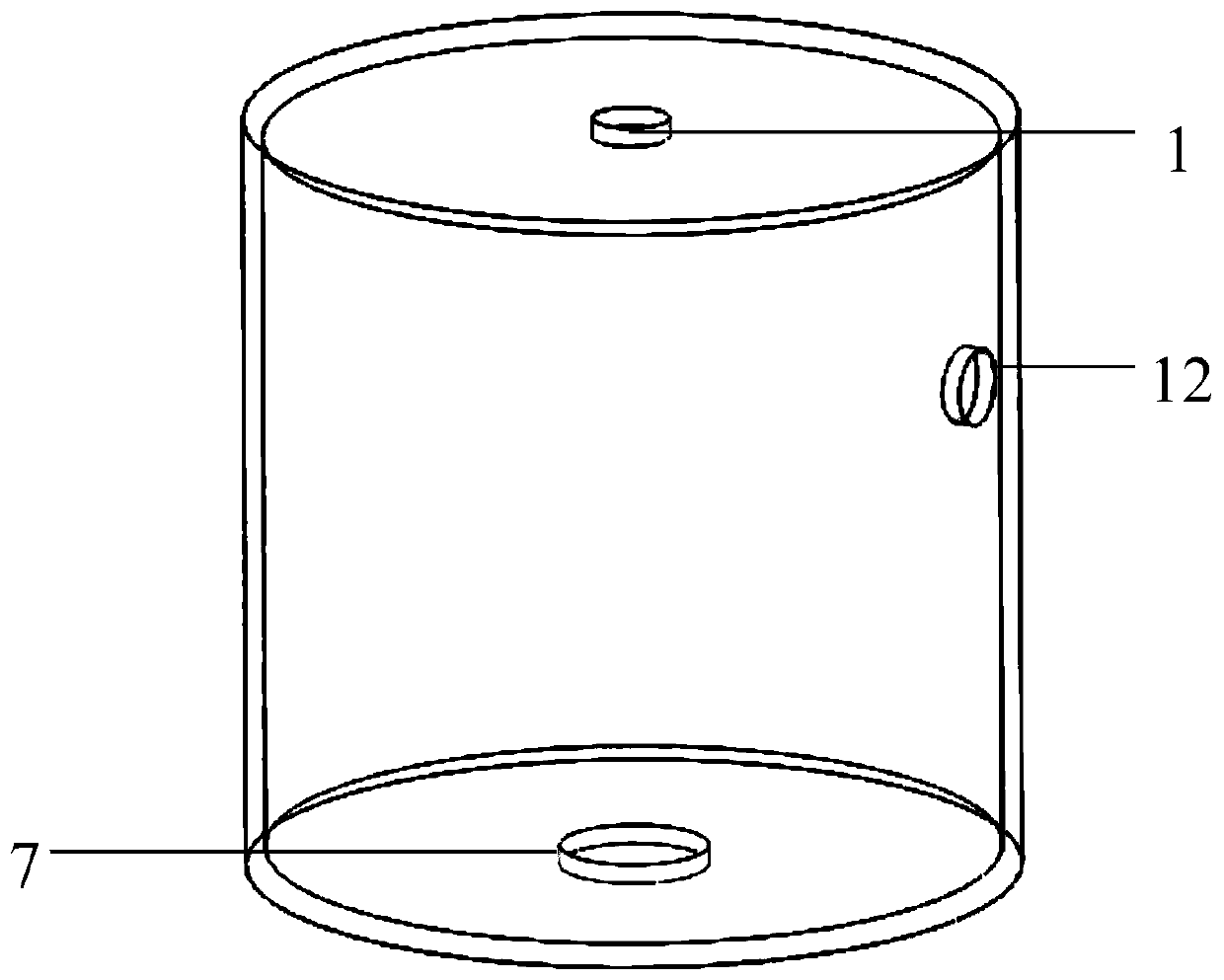

[0021] Such as figure 2 As shown, the housing 15 is cylindrical with a top surface and a bottom surface, a jet port 1 is opened on the top surface, and at least one opening 12 is provided on the side wall of the housing 15, figure 2 In the example shown, only one opening 12 is provided. In order to ensure air pressure balance in the housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com