A device and process for washing crude glycine by alcohol phase method

A technology of glycine and alcohol phase method, which is applied in the fields of chemical instruments and methods, preparation of organic compounds, organic chemistry, etc. It can solve the problems that environmental risks cannot be completely eliminated, high production costs, and high ammonium chloride content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

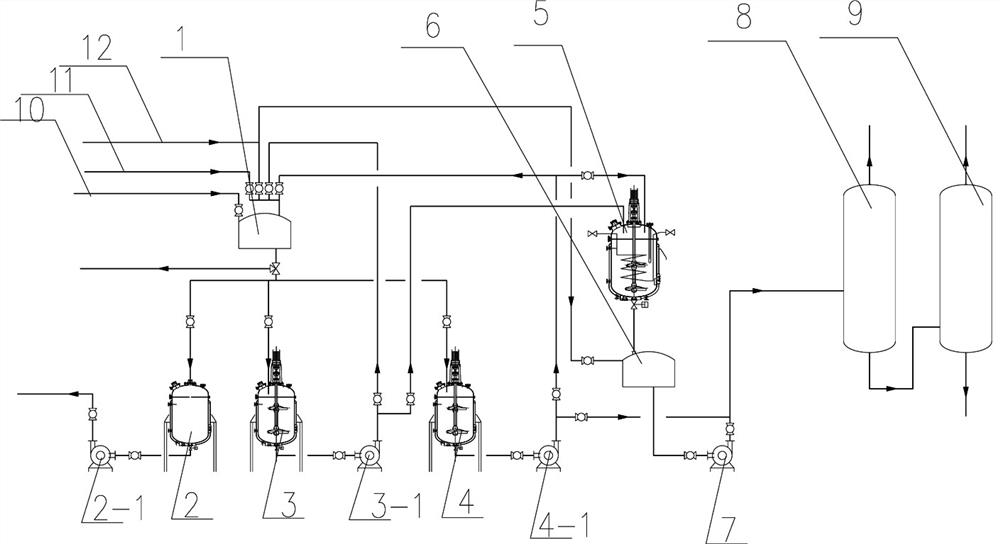

[0028] A device for washing crude glycine by an alcohol phase method, the crude glycine pipeline 10, the first methanol pipeline 11, and the second methanol pipeline 12 are connected to a glycine centrifuge;

[0029] The washing liquid of the glycine centrifuge is divided into three routes, one is connected with the concentrated methanol washing tank, and the concentrated methanol washing tank is connected with the glycine synthesis kettle through the concentrated methanol pump; the other is connected with the dilute methanol washing tank, and the dilute methanol washing tank is passed through the di The methanol pump is connected with the glycine extraction kettle and the glycine centrifuge; one path is connected with the washing water tank, and the washing water tank is connected with the glycine centrifuge through the washing water pump.

[0030] The glycine extraction kettle is divided into three paths, one path is connected to the dilute methanol washing tank through the d...

Embodiment 2

[0036]The glycine washing centrifuge adopts the L(P) LGZ-1600 flat-plate automatic bag-pull scraper discharge centrifuge from Jiangsu Saideli Pharmaceutical Machinery Manufacturing Co., Ltd. Take 300kg of crude glycine from the first batch, wash it 3 times with 600L99.7% concentrated methanol (temperature 26.7℃), centrifuge washing speed 200rpm / min, drying speed 800rpm / min, drying time for the first 2 times 5min, the third time The first drying time is 10min. Then use 600L 92% methanol to wash circularly for 10 minutes, the washing speed of centrifuge is 200rpm / min, the drying speed is 800rpm / min, and the drying time is 10min. Then wash with 600L water circulation for 10 minutes, the washing speed of the centrifuge is 200 rpm / min, the drying speed is 800 rpm / min, and the drying time is 10 minutes. Finally, rinse with 300L92% methanol for 3 times, centrifuge washing speed 200rpm / min, drying speed 850rpm / min, drying time 15min, sampling analysis main content 99.18%, chlorine co...

Embodiment 3

[0038] The glycine washing centrifuge adopts the L(P) LGZ-1600 flat-plate automatic bag-pull scraper discharge centrifuge from Jiangsu Saideli Pharmaceutical Machinery Manufacturing Co., Ltd. Take 300kg of crude glycine, wash 3 times with 900L99.7% concentrated methanol (temperature 26.7°C), centrifuge washing speed 200rpm / min, spin-drying speed 800rpm / min, the drying time of the first 2 times is 5min, and the drying time of the third time 10min. Then wash with 900L 92% methanol in a circular manner for 10 minutes, the washing speed of the centrifuge is 200 rpm / min, the drying speed is 800 rpm / min, and the drying time is 10 minutes. Then use 900L water to circulate and wash for 10 minutes, the centrifuge washing speed is 200rpm / min, the drying speed is 800rpm / min, and the drying time is 10min. Finally, rinse with 300L92% methanol for 3 times, centrifuge washing speed 200rpm / min, drying speed 850rpm / min, drying time 15min, sampling and analysis main content 98.98%, chlorine co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com