Material washing method for industrial-grade glycine crude product

A glycine, industrial-grade technology, applied in non-aqueous solvents to produce qualified products of glycine, washing materials of industrial-grade crude glycine, can solve the problems of low conversion rate of glycine, non-recycling, high equipment operation and maintenance costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

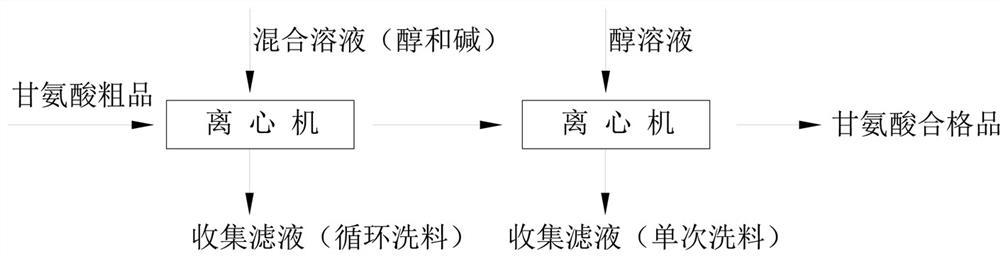

Method used

Image

Examples

Embodiment 1

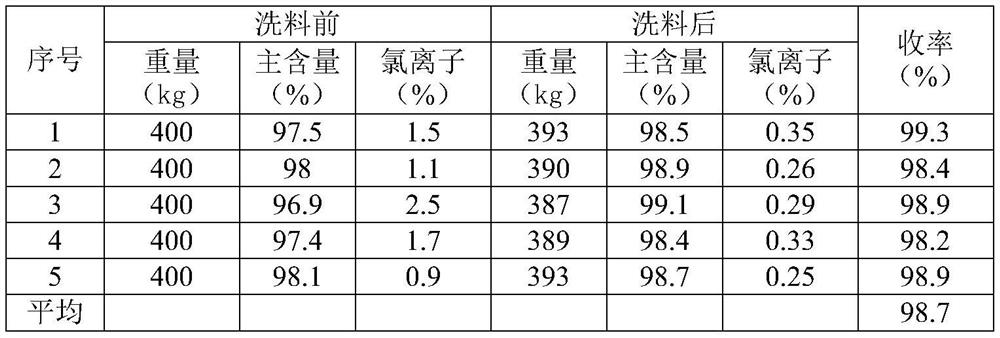

[0020] The industrial-grade glycine washing centrifuge adopts the L(P)LGZ-1600 flat-plate automatic bag-pull scraper bottom discharge centrifuge from Jiangsu Saideli Pharmaceutical Machinery Manufacturing Co., Ltd. Glycine crude product produced by any new glycine technology enters the centrifuge, after conventional feeding and centrifugation (solid material has been evenly distributed on the filter cloth of the centrifuge and there is no collapse, 400kg, the main content of glycine is 96.9-98.1%) , chloride ion content 0.9-2.5%), adopt this method to carry out washing treatment: (1) earlier the triethylamine 100L of the ethanol 500L of 99% mass fraction (the same below) and 99% content are configured into mixed solution for the first time , use a special washing tank for storage, and use a pump to connect the feed inlet of the centrifuge and the filtrate outlet to the washing tank to form a circulating washing circuit. (2) The first washing: adjust the washing speed of the ce...

Embodiment 2

[0023] The method and steps are the same as in Example 1, except that step (1) is as follows: 500 L of ethanol with a mass fraction of 99% and 150 L of dimethylamine with a content of 99% are configured to form the mixed solution for the first time, and stored in a special washing tank. At the same time, a pump is used to connect the feed inlet of the centrifuge and the outlet of the filtrate to the washing tank to form a circulation washing circuit. After the moisture content of glycine is dried by a 90°C tray dryer, the granules are better. Repeat the above operation 5 times, and the dry weight, product quality and yield after washing (the same below) are shown in Table 2 below.

[0024]

[0025]

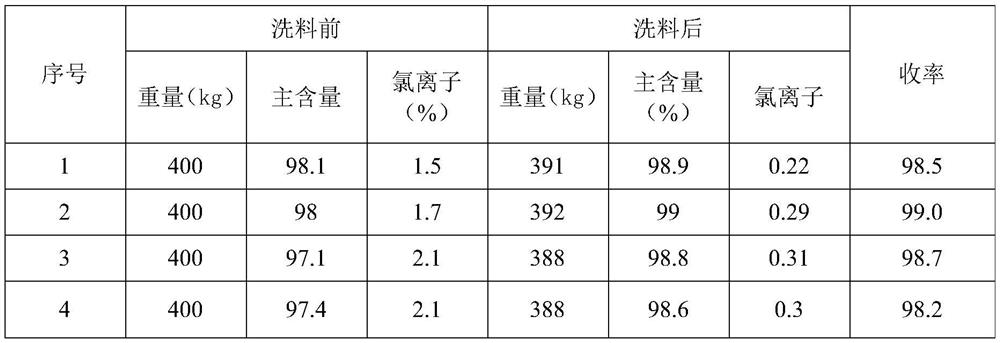

Embodiment 3

[0027] The method and steps are the same as in Example 1, only step (1) is: first configure 500 L of ethanol with a mass fraction of 99% and caustic soda 10 kg into the mixed solution for the first time, store it in a special washing tank, and simultaneously use a pump to centrifugally The feed port of the machine and the filtrate outlet are connected with the washing tank to form a circulating washing circuit. After the moisture content of glycine is dried by a 90°C tray dryer, the granules are better. After the moisture content of glycine is dried by a 90°C tray dryer, the granules are better. Repeat the above operation 5 times, and the dry weight, product quality and yield after washing (the same below) are shown in Table 3 below.

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com