Bisphenol-containing self-healing thermally-reversible cross-linked polyurethane and production method thereof

A technology for cross-linking polyurethane and bisphenol, applied in the field of polyurethane, can solve the problems of difficult recycling and reuse of chemically cross-linked polyurethane, and achieve the effects of broadening the performance adjustment method, solving environmental problems, and restoring the strength completely.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

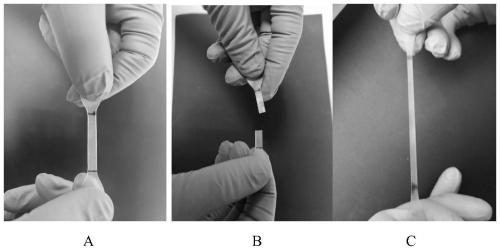

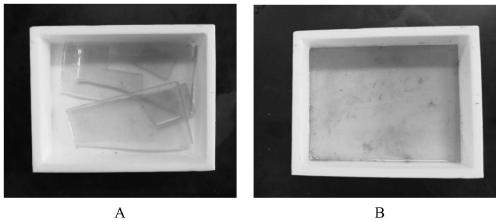

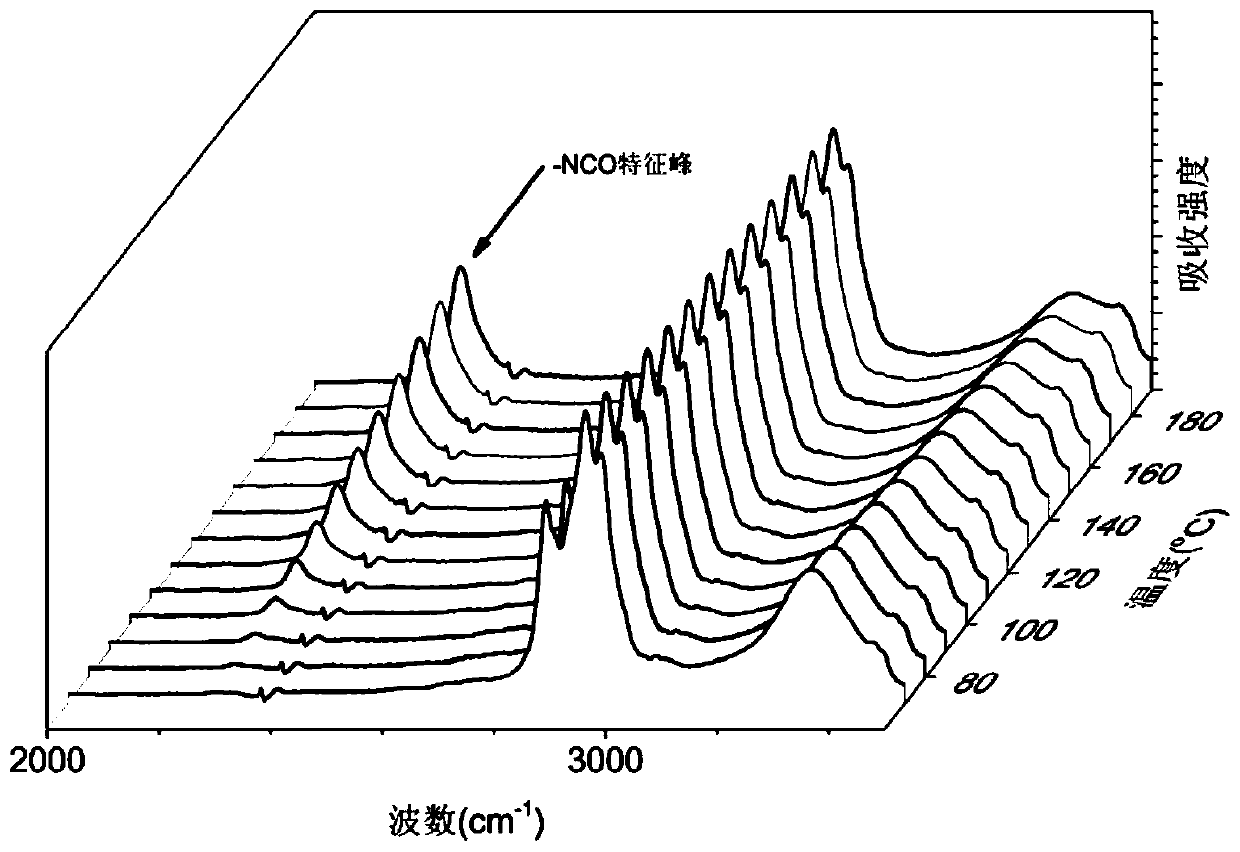

[0033] React polyethylene glycol, bisphenol S, hexamethylene diisocyanate, and hexamethylene diisocyanate trimer at a molar ratio of functional alcoholic hydroxyl, phenolic hydroxyl, and isocyanate groups of 1:1:2, and the added mass is Triethylenediamine with 0.5% of the total mass of the above-mentioned reactants is used as a catalyst, and it is stirred evenly at 80°C; after the mixture is clarified, pour the mixture into a mold, control the temperature at 60°C, and cure for 12 hours to obtain a reproducible . Self-healing thermally reversible crosslinking polyurethane, the thermally reversible crosslinking temperature of which is above 70°C.

Embodiment 2

[0035] Bisphenol AF, castor oil, and isophorone diisocyanate are reacted at a molar ratio of phenolic hydroxyl group, alcoholic hydroxyl group, and isocyanate group at a molar ratio of 1:1:2.1, and the added mass is 0.5% of the total mass of the above reactants. Use 0.2% dibutyltin dilaurate as a catalyst, add tetrahydrofuran to accelerate dissolution, and stir evenly; after the mixture is clarified, pour the mixture into a mold, control the temperature at 50°C, and cure for 7 hours to obtain reproducible, self-repairing Thermally reversible crosslinking polyurethane, its thermally reversible crosslinking temperature is above 90°C.

Embodiment 3

[0037]The molar ratio of bisphenol A, polybutylene adipate diol, isophorone diisocyanate, and hexamethylene diisocyanate to functional group phenolic hydroxyl, alcoholic hydroxyl, and isocyanate groups is 1:1:1.9 Reaction, adding 0.5% triethylenediamine and 0.1% dibutyltin dilaurate as a catalyst in the total mass of the above-mentioned reactants, stirring evenly at 90°C; after the mixture is clarified, pour the mixture into a mold, and control the temperature to 90°C, curing for 3 hours, you can get reproducible, self-healing thermally reversible crosslinked polyurethane, and its thermally reversible crosslinking temperature is above 120°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com