Brushless synchronous generator salient pole exciter stator and manufacturing method thereof

A synchronous generator, salient-pole technology, applied in the manufacture of motor generators, stator/rotor bodies, magnetic circuits, etc., can solve the problem of cumbersome process, not much improvement, increase in size and weight of generators, etc. problem, to achieve the effect of obvious downward trend, improved response speed, and improved dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and the embodiments of the 50kW / 400V brushless synchronous generator.

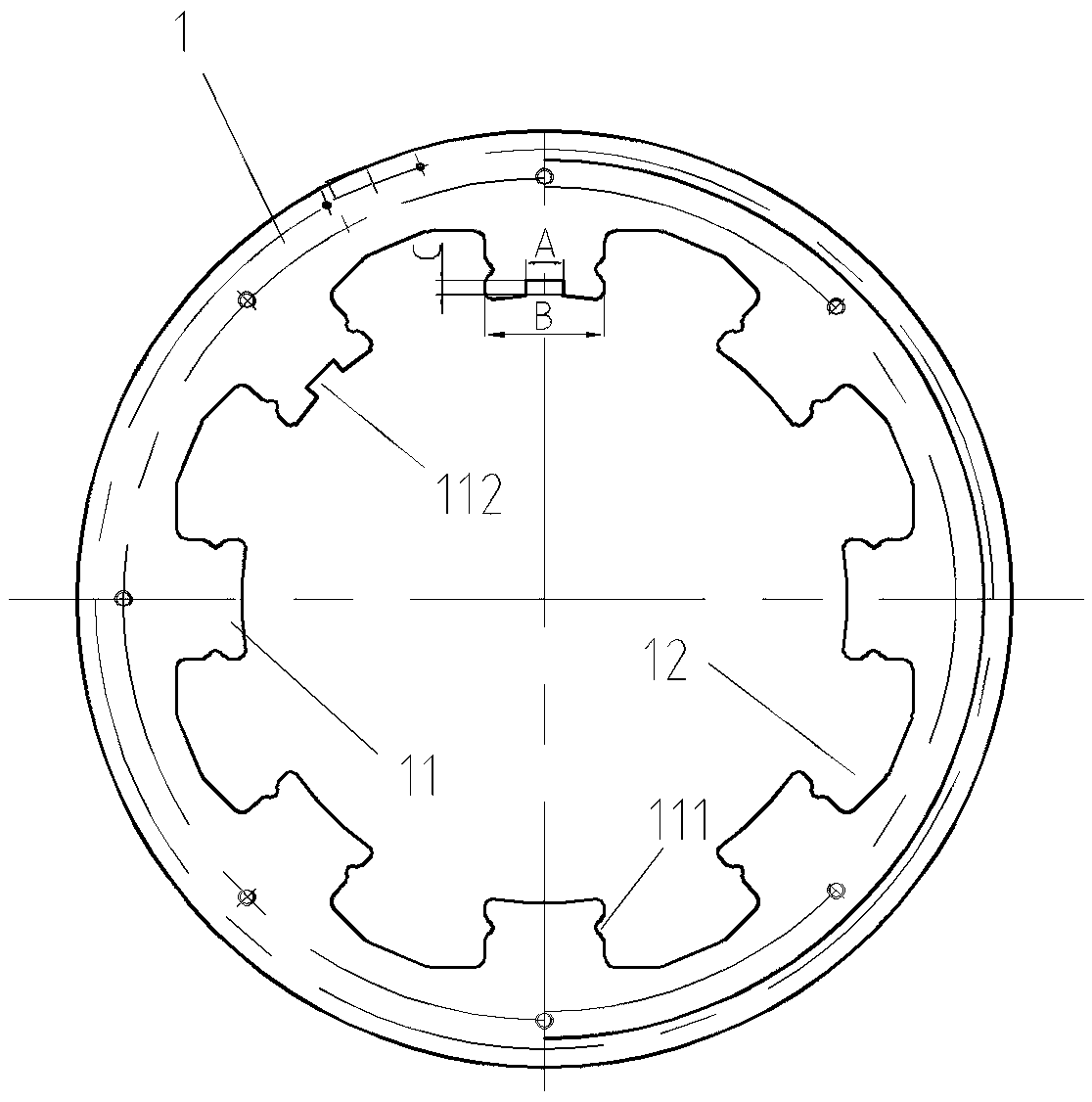

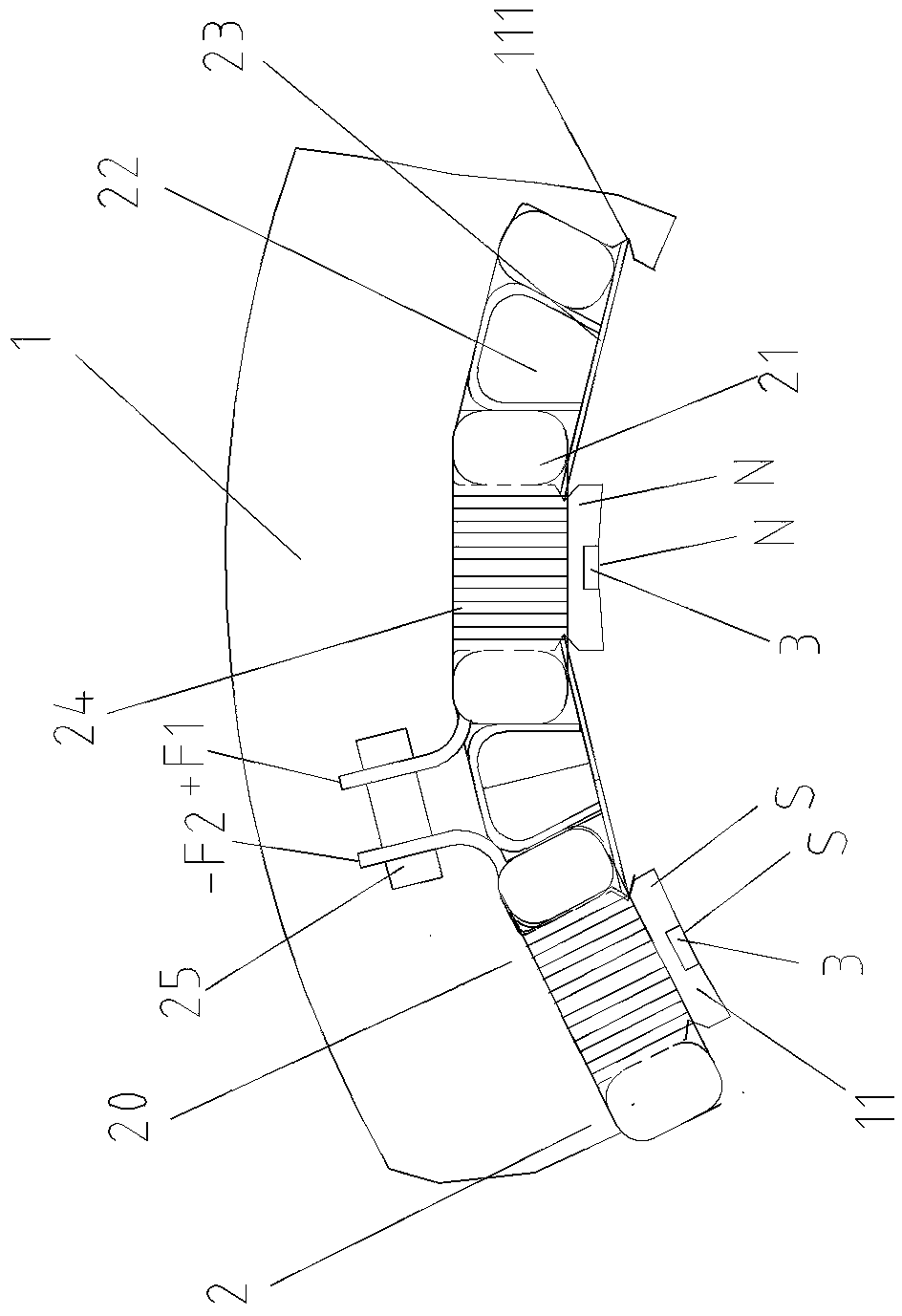

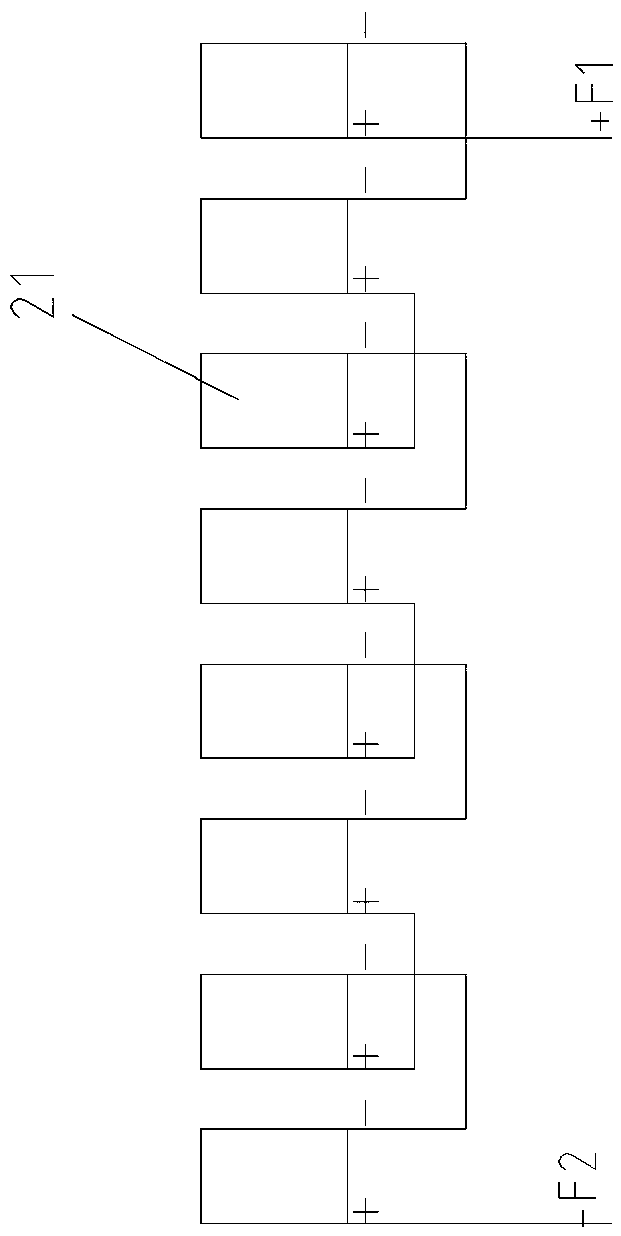

[0035] Such as figure 1 with figure 2 As shown, this embodiment includes a magnetic pole yoke ring 1 and 8 magnetic pole windings 2. The magnetic pole winding 2 includes a coil 21, a slot wedge 22 and a fixing plate 23. The inner holes of the circular magnetic pole yoke ring 1 are evenly distributed with 8 holes facing the pole yoke. The salient poles 11 extending radially from the center of the inner hole of the ring, and the wound coils 21 are respectively sleeved on the salient poles 11 covered with an insulating layer, and the two ends of each coil 21 are respectively connected with adjacent coils 21 to form a coil group 20 . Coils 21 are radially spaced with a plurality of binding bands 24 binding the cross section of the coils. Slot wedges 22 are embedded and fixed between two adjacent coils 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com