Device and method for wet-process deacidification

A kind of equipment and deacidification technology, which is applied in the field of economical wet deacidification equipment and high efficiency, to avoid high-salt wastewater, low raw material cost, and reduce operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

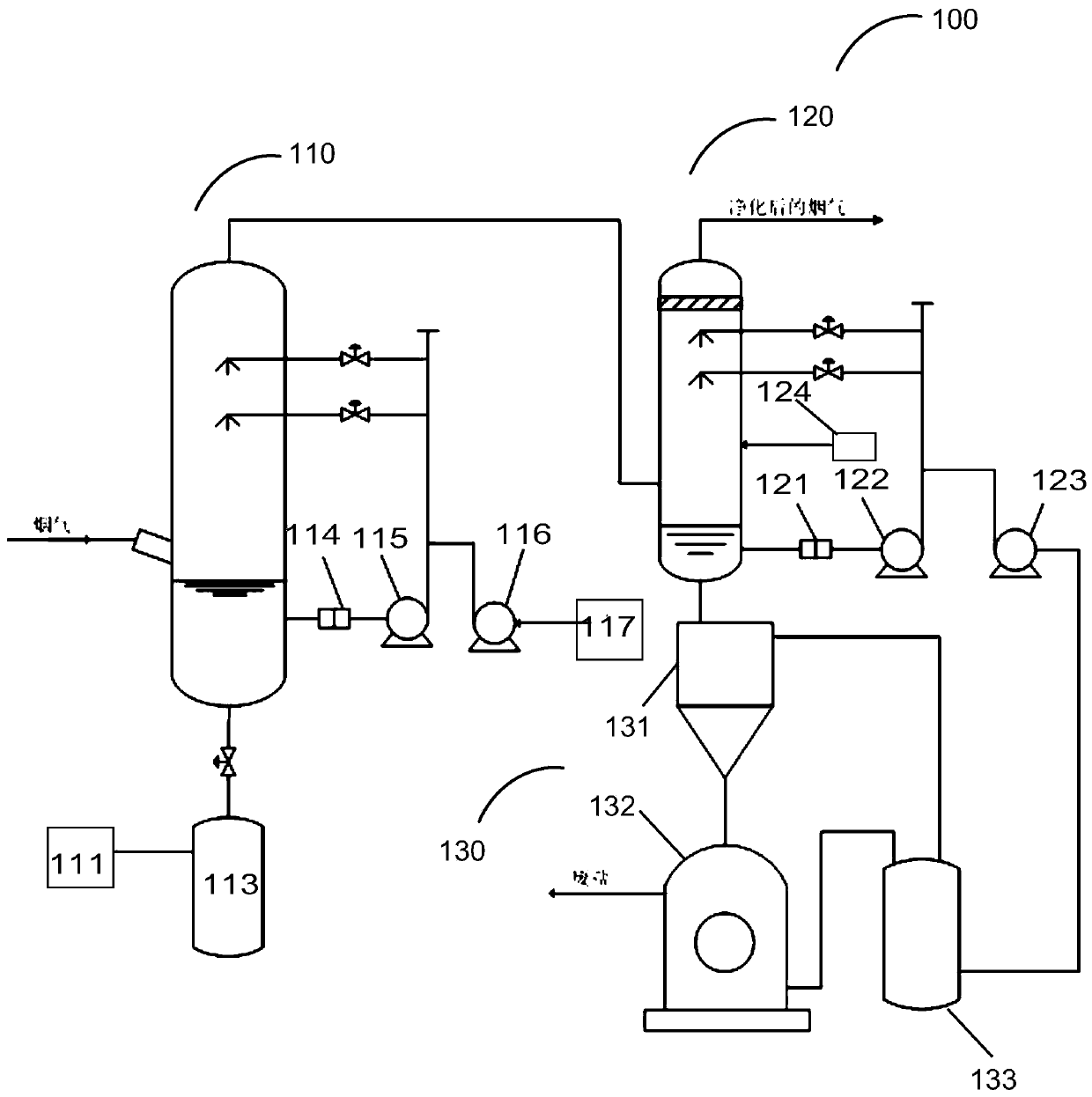

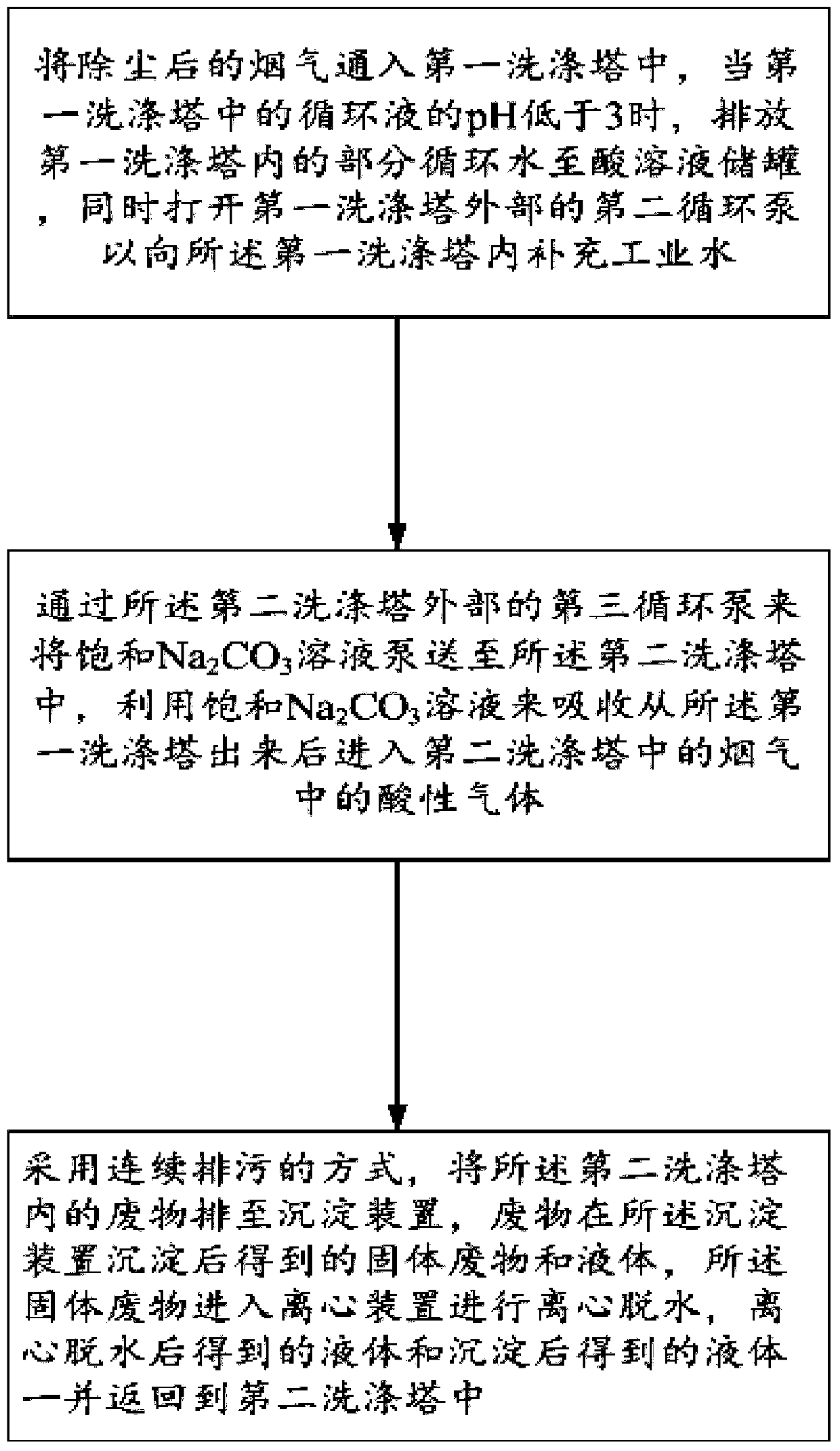

[0073] A flue gas after dedusting, the main acid gas composition is HCl content of 8000mg / Nm 3 , SO 2 The content is 2000mg / Nm 3 , enter the first washing tower 110, and the circulating liquid is pumped into the first washing tower 110 through the first filter 114 by the first circulating pump 115 to absorb the acid liquid; when the pH of the circulating liquid is lower than 3, the partial circulation in the discharge tower liquid to the acid solution storage tank 113 (spent acid storage tank), and simultaneously open the second circulation pump 116 to replenish industrial water. The acid solution storage tank 113 (spent acid storage tank) is used for sewage treatment or other facilities of the factory such as waste disposal production line for pH adjustment.

[0074] The flue gas washed by the first scrubber 110 enters the second scrubber 120 . The circulating liquid is pumped to the second washing tower 120 through the second filter 121 by the third circulating pump 122 t...

Embodiment 2

[0076] A flue gas after dedusting, the main acid gas composition is HCl content of 8000mg / Nm 3 , SO 2 The content is 12000mg / Nm 3 , enter the first washing tower 110, and the circulating liquid is pumped into the first washing tower 110 through the first filter 114 by the first circulating pump 115 to absorb the acid liquid; when the pH of the circulating liquid is lower than 3, the partial circulation in the discharge tower liquid to the acid solution storage tank 113 (spent acid storage tank), and simultaneously open the second circulation pump 116 to replenish industrial water. The acid solution storage tank 113 (spent acid storage tank) is used for sewage treatment or other facilities of the factory such as waste disposal production line for pH adjustment.

[0077] The flue gas washed by the first scrubber 110 enters the second scrubber 120 . The circulating liquid is pumped to the second washing tower 120 through the second filter 121 by the third circulating pump 122 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com