Desulfurization absorption tower oxidation air delivery device for thermal power plant

A technology for oxidizing wind in thermal power plants and towers, applied in chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve problems such as low oxygen intake, insufficient oxygen in time, and influence on desulfurization reaction speed, etc., to achieve The effect of improving the uniformity and speeding up the desulfurization reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

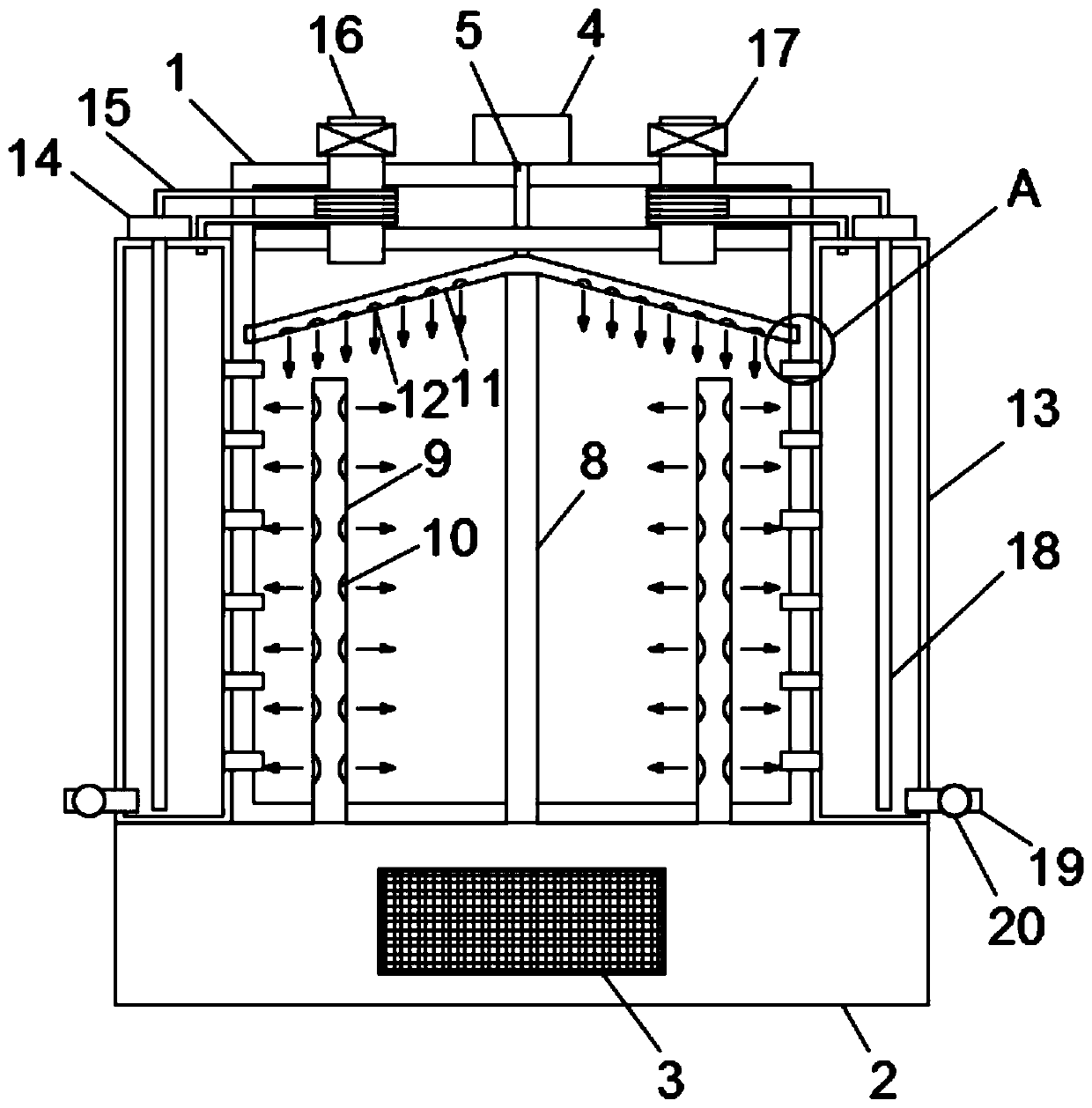

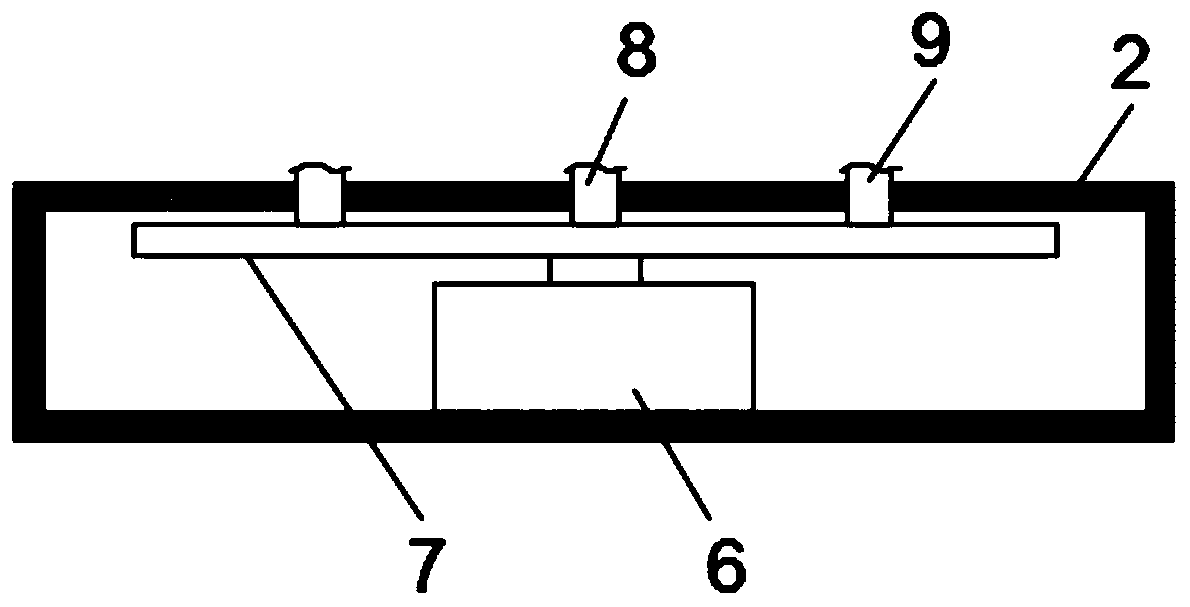

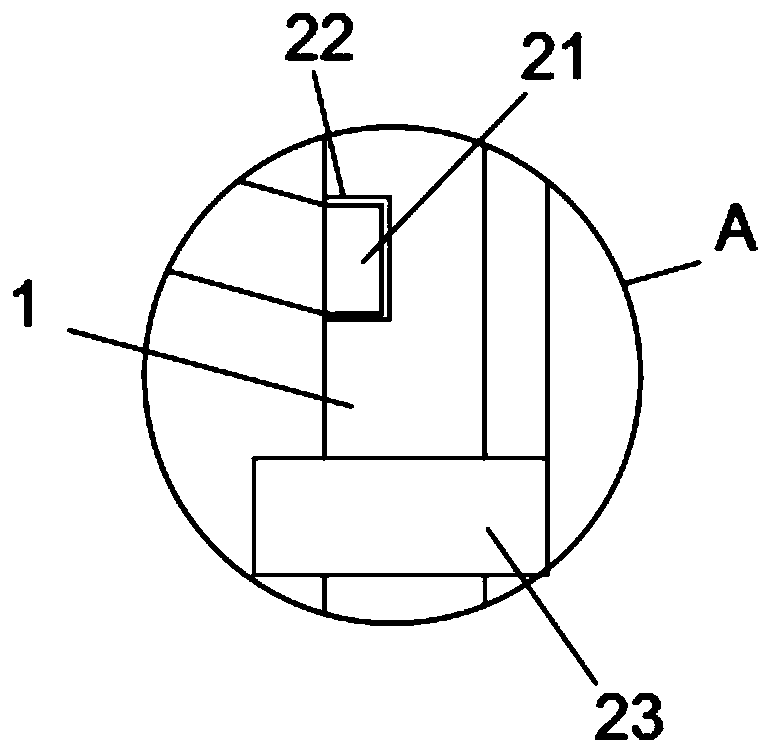

[0026] refer to Figure 1-3 , a desulfurization absorption tower oxidizing wind conveying device for a thermal power plant, comprising an absorption tower 1, the bottom side of the absorption tower 1 is fixedly connected with a blast chamber 2, and the blast chamber 2 is provided with a blast mechanism, and the blast mechanism includes a blower 6 , the blower 6 is fixedly installed in the blast chamber 2, the output end of the blower 6 is fixedly connected with a first splitter plate 7, a cavity is opened in the first splitter plate 7, and the bottom end of the first air delivery pipe 8 is rotatably connected to the first splitter plate 7. On a splitter plate 7, the bottom end of the second air delivery pipe 9 is fixedly connected to the first splitter plate 7, oxygen is transported through the blower 6, and the air flow is distributed to the first air delivery pipe after passing through the cavity of the first splitter plate 7 8 and the second air delivery pipe 9, and then ca...

Embodiment 2

[0032] refer to Figure 4 , a desulfurization absorption tower oxidizing wind conveying device for a thermal power plant, comprising an absorption tower 1, the bottom side of the absorption tower 1 is fixedly connected with a blast chamber 2, and the blast chamber 2 is provided with a blast mechanism, and the blast mechanism includes a blower 6 , the clapboard is rotatably connected with a rotating shaft 24, the rotating shaft 24 is fixedly connected with a fan blade 25, the rotating shaft 24 is fixedly connected with the first air delivery pipe 8, and the gas delivery end of the blower 6 is rotatably connected with an air delivery pipe, and the air delivery pipe extends to the absorption tower One end of 1 is fixedly connected with a second splitter plate 26 , and both the first air delivery pipe 8 and the second air delivery pipe 9 are fixedly connected with the second splitter plate 26 .

[0033] The absorption tower 1 is fixedly connected with an exhaust pipe 16 symmetrica...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap