Adhesive and preparation method thereof

An adhesive, polyvinyl butyral resin technology, applied in the direction of adhesives, adhesive types, non-polymer adhesive additives, etc., can solve the problems of affecting application, harsh production environment, affecting the health of production workers, etc. , to achieve the effect of low cost, simple and easy preparation method and moderate viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

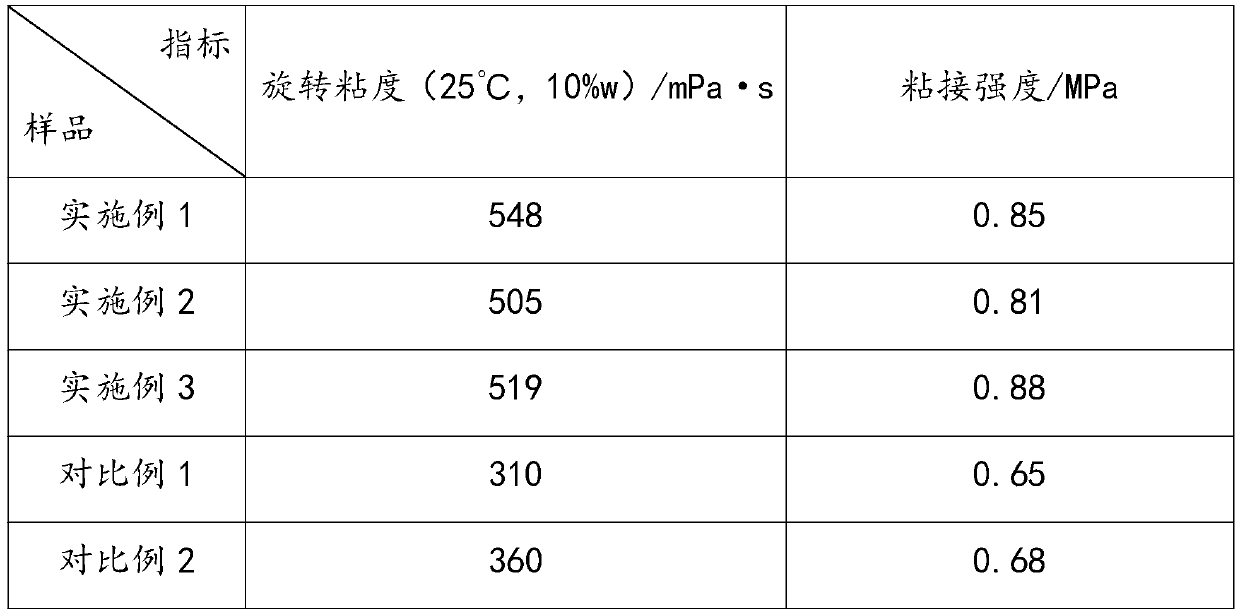

Examples

Embodiment 1

[0018] A, polyvinyl butyral resin 20kg, aldehyde and ketone resin 9kg, ethanol 80kg, n-butanol 18kg, formaldehyde solution 8kg, melamine 4kg and dibutyl phthalate 24kg, the massfraction of formaldehyde solution is 40%, poly The rotational viscosity of vinyl butyral resin in 10% ethanol solution at 25°C is 85mPa·s;

[0019] B. Mix the formaldehyde aqueous solution and melamine, adjust the pH value to 8, then heat to 80°C and react for 50 minutes, then add dibutyl phthalate, and stir and cool to room temperature to obtain a curing agent;

[0020] C. Mix polyvinyl butyral resin, aldehyde and ketone resin, ethanol and n-butanol until completely dissolved to obtain the adhesive stock solution;

[0021] D. Slowly add the curing agent obtained in step B to the adhesive stock solution obtained in step C to obtain the adhesive.

Embodiment 2

[0023] A, polyvinyl butyral resin 22kg, aldehyde and ketone resin 9kg, ethanol 78kg, n-butanol 19kg, formaldehyde solution 10kg, melamine 5kg and dibutyl phthalate 22kg, the massfraction of formaldehyde solution is 42%, poly The rotational viscosity of vinyl butyral resin in 10% ethanol solution at 25°C is 90mPa·s;

[0024] B. Mix the formaldehyde aqueous solution and melamine, adjust the pH value to 8, then heat to 80°C and react for 60 minutes, then add dibutyl phthalate, and stir and cool to room temperature to obtain a curing agent;

[0025] C. Mix polyvinyl butyral resin, aldehyde and ketone resin, ethanol and n-butanol until completely dissolved to obtain the adhesive stock solution;

[0026] D. Slowly add the curing agent obtained in step B to the adhesive stock solution obtained in step C to obtain the adhesive.

Embodiment 3

[0028] A, polyvinyl butyral resin 20kg, aldehyde and ketone resin 8kg, ethanol 82kg, n-butanol 18kg, formaldehyde solution 8kg, melamine 5kg and dibutyl phthalate 22kg, the massfraction of formaldehyde solution is 42%, poly The rotational viscosity of vinyl butyral resin in 10% ethanol solution at 25°C is 90mPa·s;

[0029] B. Mix the formaldehyde aqueous solution and melamine, adjust the pH value to 8, then heat to 80°C and react for 60 minutes, then add dibutyl phthalate, and stir and cool to room temperature to obtain a curing agent;

[0030] C. Mix polyvinyl butyral resin, aldehyde and ketone resin, ethanol and n-butanol until completely dissolved to obtain the adhesive stock solution;

[0031] D. Slowly add the curing agent obtained in step B to the adhesive stock solution obtained in step C to obtain the adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotational viscosity | aaaaa | aaaaa |

| Rotational viscosity | aaaaa | aaaaa |

| Rotational viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com