Elastic yarn, and manufacturing method and fabric thereof

A manufacturing method and technology of elastic yarn, applied in the direction of fabric, yarn, textile, etc., can solve the problems of high shrinkage rate, easy wrinkling, high production cost, and achieve high elastic recovery rate, excellent shape retention, and excellent elasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

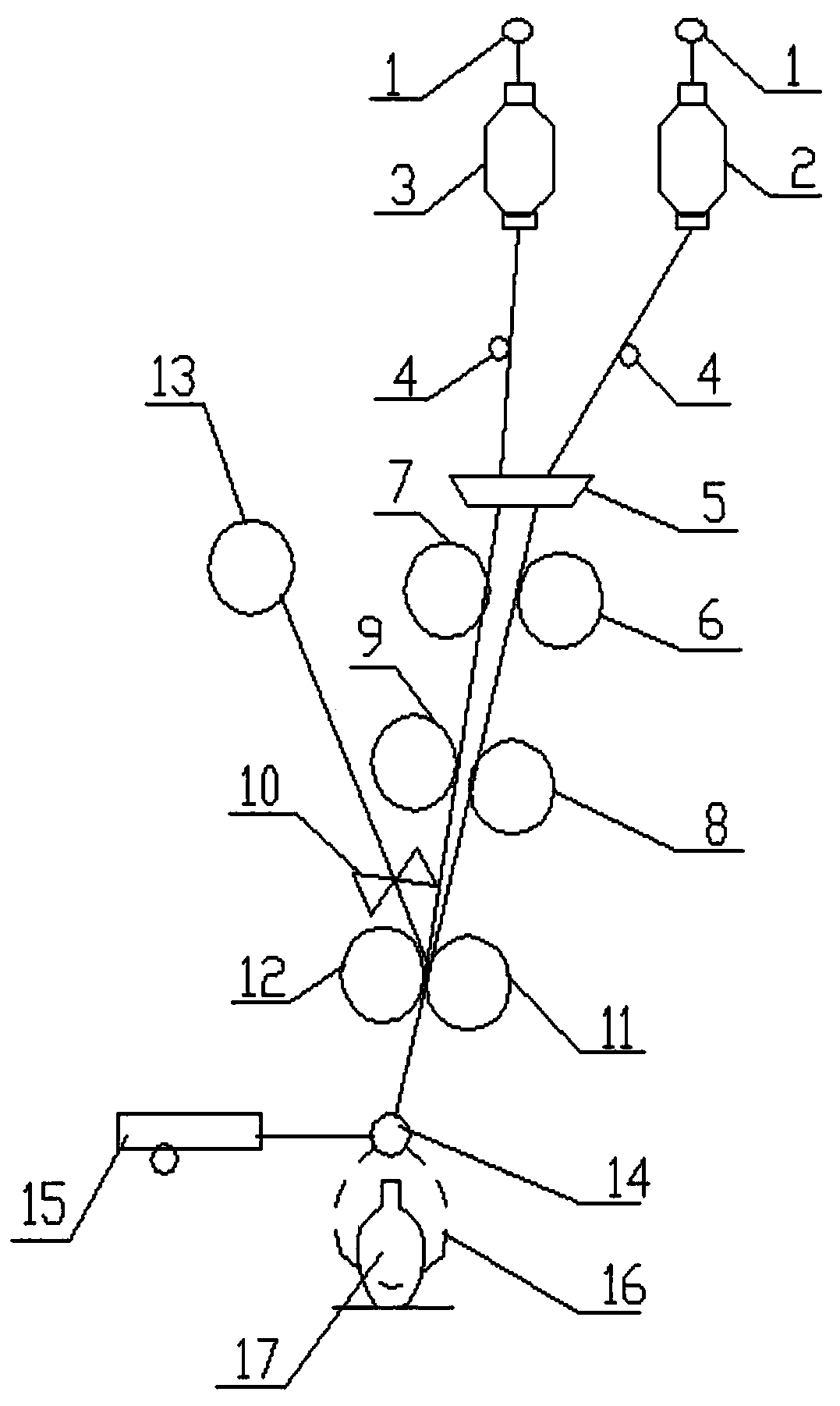

[0032] figure 1 It is the preparation process diagram of the elastic yarn of the present invention, wherein, 1-spinning frame hanging spindle, 2, 3-roving, 4-yarn guide hook, 5-bell mouth, 6, 7-back roller, 8,9-middle roller , 10-wire guide device, 11-front roller, 12-front top roller, 13-elastic core fiber, 14-yarn guide hook, 15-leaf plate, 16-spinning balloon, 17-elastic yarn.

[0033] Depend on figure 1 It can be seen that the present invention divides the rovings spun from short fibers into two groups and puts them on the spindles of the spinning frame. Between, form the short cotton fiber bundle; Then the elastic core fiber is unwound and drafted through the guide wire device, and the elastic core fiber after drafting is merged with the short cotton fiber bundle at the front roller; after passing through the front roller output, Cooperate with the leaf plate through the yarn guide hook, twist and wind the bobbin on the spinning balloon to obtain the elastic yarn.

[0...

Embodiment 1

[0039] Cotton staple fiber is spun into roving, and described roving is divided into two groups and placed on the spindle of spinning machine; The average length of roving fiber is 30mm, roving quantitative 5.6g / 10m, design twist 4.87;

[0040] After the two groups of rovings pass through the guide hook, the bell mouth, the back roller and the middle roller in sequence, they enter between the front roller and the front top roller to form short cotton fiber bundles; wherein the bell mouth specification is 2.5mm*6mm;

[0041] The elastic core fiber Lycra is unwound and drafted through the guide wire device, and the draft ratio is 2.0, and the elastic core fiber after drafting is merged with the cotton staple fiber bundle at the front roller, and the elastic core fiber is placed on the cotton staple fiber. the middle of the whiskers;

[0042] After being output by the front roller, it is twisted and wound into bobbins on the spinning balloon through the yarn guide hook and leaf p...

Embodiment 2

[0044] Cotton staple fiber is spun into roving, and described roving is divided into two groups and placed on spinning frame hanging spindle; The average length of roving fiber is 30mm, roving quantitative 5.6g / 10m, design twist 48.7;

[0045] After the two groups of rovings pass through the guide hook, the bell mouth, the back roller and the middle roller in sequence, they enter between the front roller and the front top roller to form short cotton fiber bundles; wherein the bell mouth specification is 2.5mm*6mm;

[0046] The elastic core fiber Lycra is unwound and drafted through the guide wire device, and the draft ratio is 2.0, and the elastic core fiber after drafting is merged with the cotton staple fiber bundle at the front roller, and the elastic core fiber is placed on the cotton staple fiber. the middle of the whiskers;

[0047] After being output by the front roller, it is twisted and wound into bobbins on the spinning balloon through the yarn guide hook and leaf pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com