Zinc air button cell and preparation method thereof

A button battery and zinc-air technology, which is applied in fuel cells, battery electrodes, battery covers/end covers, etc., can solve the problems of easy oxidation and discoloration of the negative electrode cover, low battery discharge capacity, etc., and increase the amount of negative electrode materials and improve Discharge capacity, effect of suppressing hydrogen generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of above-mentioned zinc-air button battery comprises the following steps:

[0035] S1. Preparation of positive electrode powder for catalytic layer: Weigh 30 parts of activated carbon, 15 parts of carbon black, 35 parts of activated manganese dioxide, and 23 parts of polytetrafluoroethylene, and add them to the stirring container in sequence. Stir evenly under the condition of 60% RH to obtain the catalyst layer cathode powder;

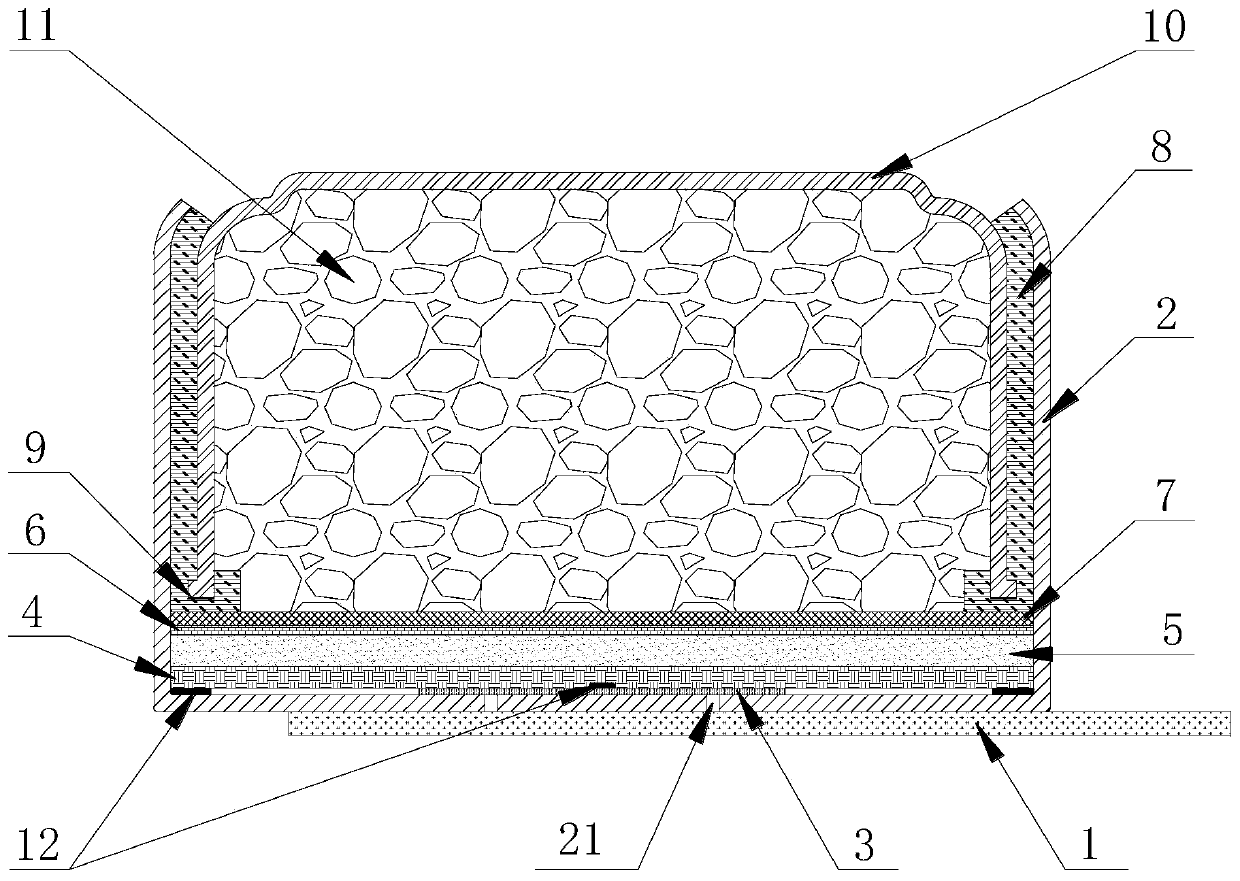

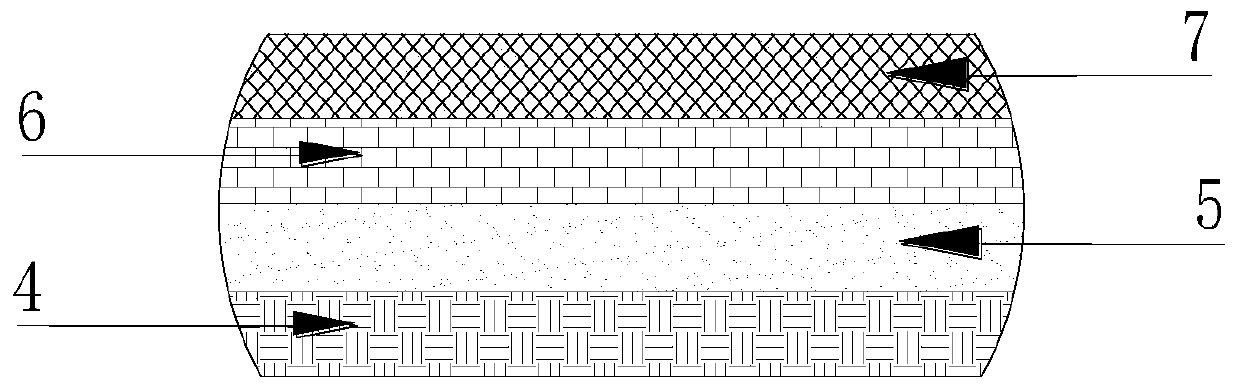

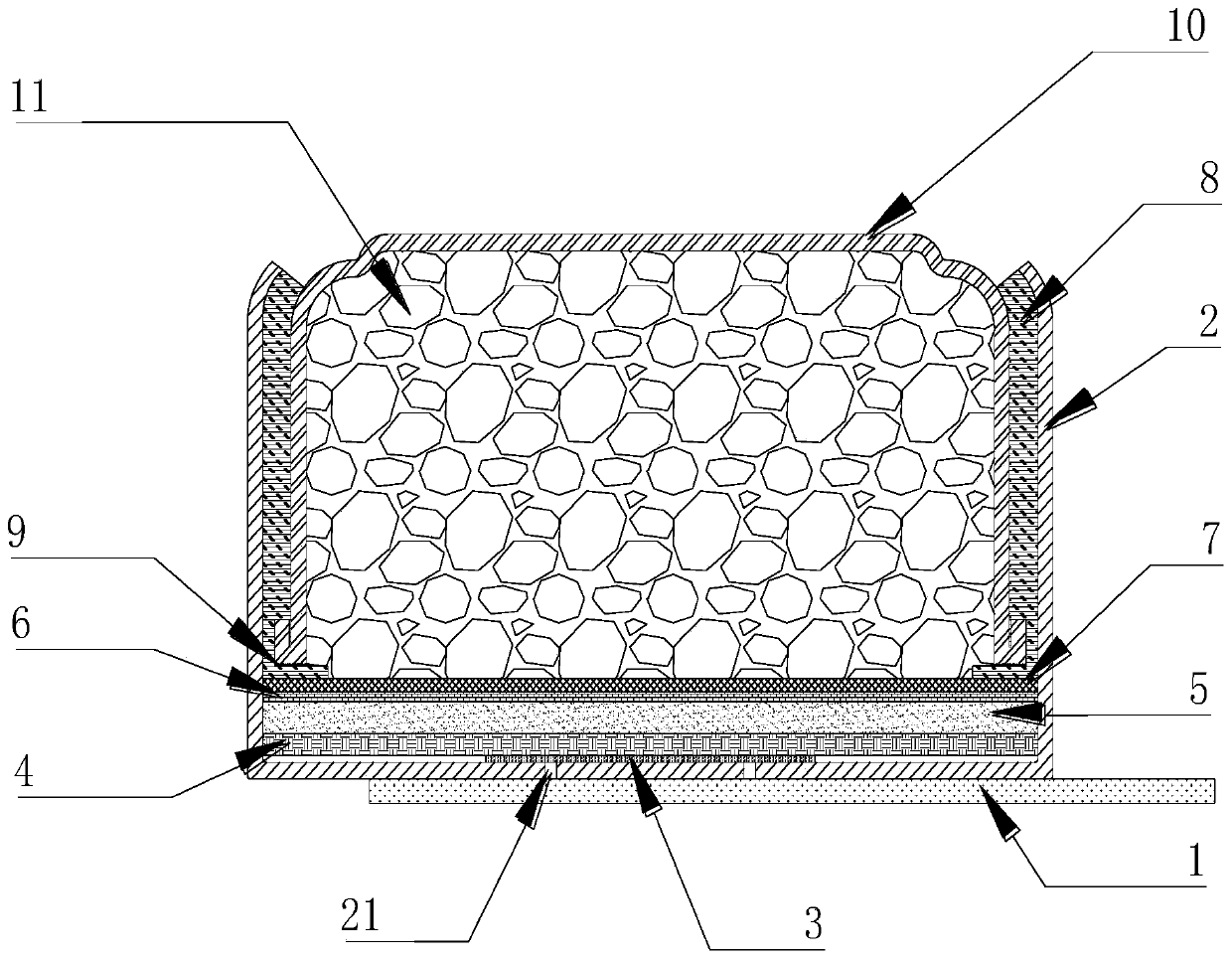

[0036] S2. Preparation of the positive electrode plate: the polytetrafluoroethylene gas permeable membrane, the positive electrode powder of the catalytic layer, the conductive nickel mesh, and the diaphragm paper are stacked on a rolling machine and rolled to obtain the positive electrode plate;

[0037] S3. the preparation of negative electrode material, comprises:

[0038] S3a. Preparation of negative electrode zinc powder: Weigh 160 parts of zinc powder, 3 parts of polyacrylic acid, and 1 part of sodium polyacrylate,...

Embodiment 2

[0053] The preparation method of above-mentioned zinc-air button battery comprises the following steps:

[0054] S1. Preparation of positive electrode powder for catalytic layer: Weigh 30 parts of activated carbon, 13 parts of graphite, 35 parts of activated manganese dioxide, and 23 parts of polytetrafluoroethylene, and add them to a stirring container in sequence. Stir evenly under the condition of 60% RH to obtain the catalyst layer cathode powder;

[0055] S2. Preparation of the positive electrode plate: the polytetrafluoroethylene gas permeable membrane, the positive electrode powder of the catalytic layer, the conductive nickel mesh, and the diaphragm paper are stacked on a rolling machine and rolled to obtain the positive electrode plate;

[0056] S3. the preparation of negative electrode material, comprises:

[0057] S3a. Preparation of negative electrode zinc powder: Weigh 160 parts of zinc powder, 3 parts of carboxymethyl cellulose, and 1 part of sodium polyacrylate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com