Low-height and high-reliability high-voltage wire for fuel gas and fabrication method of high-voltage wire

A high-voltage wire, low-height technology, applied in the direction of cable/conductor manufacturing, conductors, electrical components, etc., can solve problems such as the inability to design joint heat dissipation structures, high compression ratio of gas engines, and easy-aging internal resistors, etc., to reduce the height Piezoelectric flashover phenomenon, high-efficiency processing and production, and improved heat transfer and dissipation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

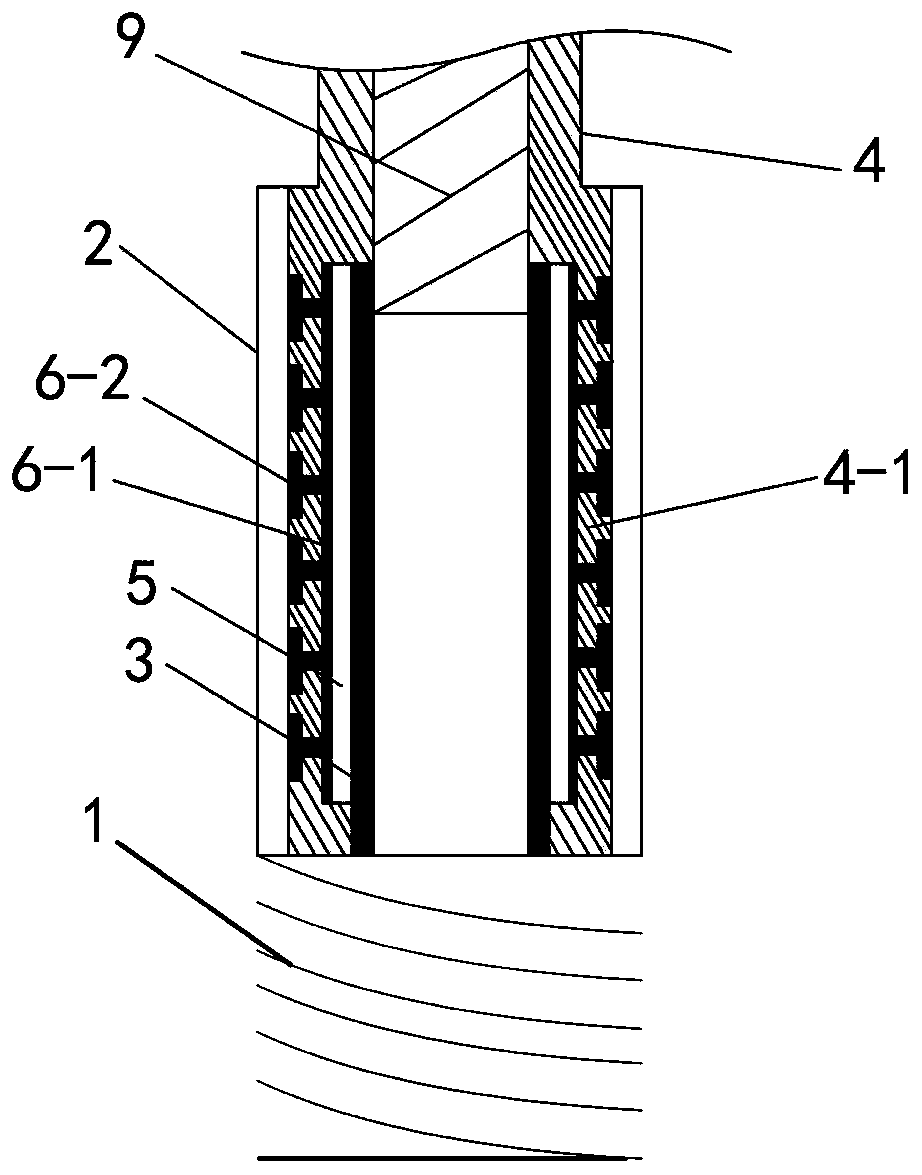

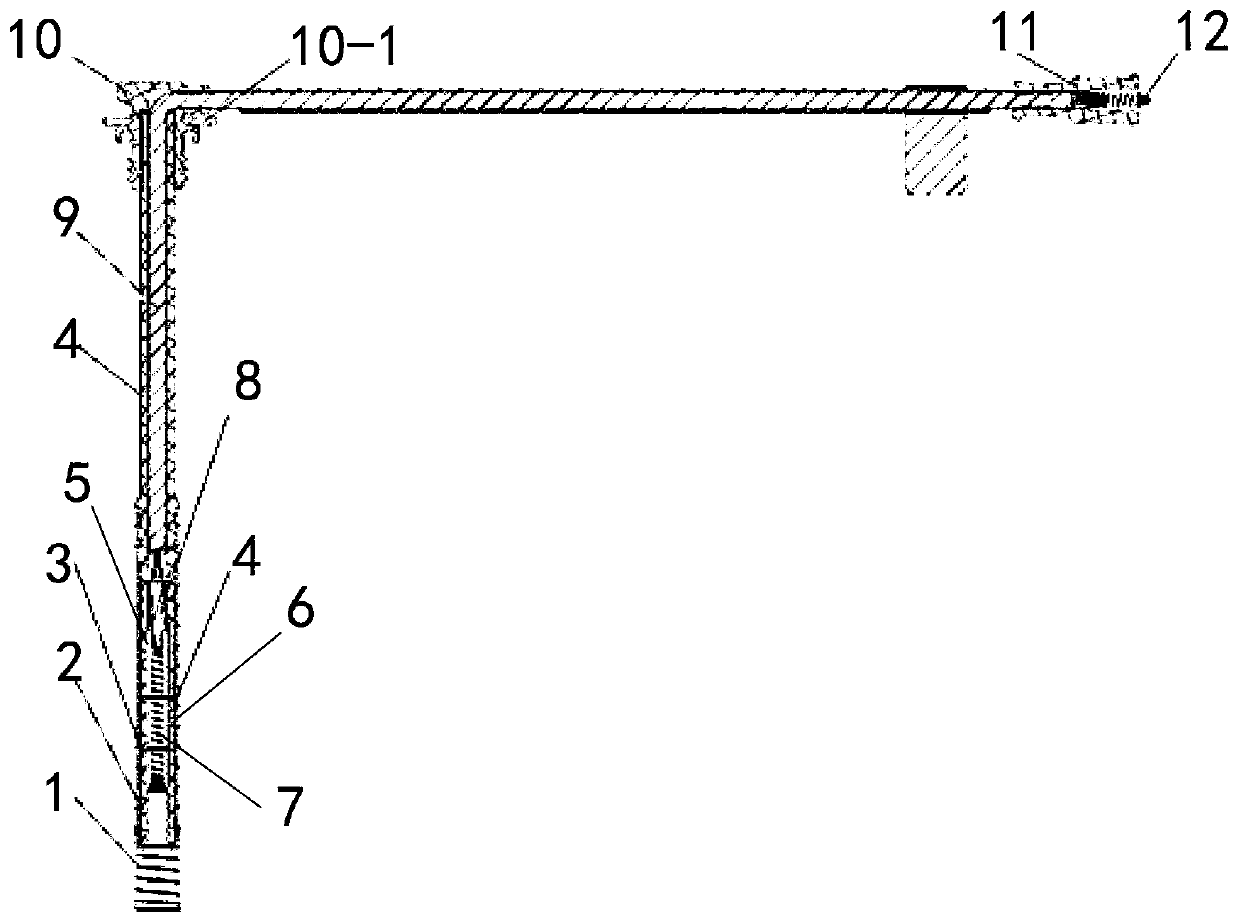

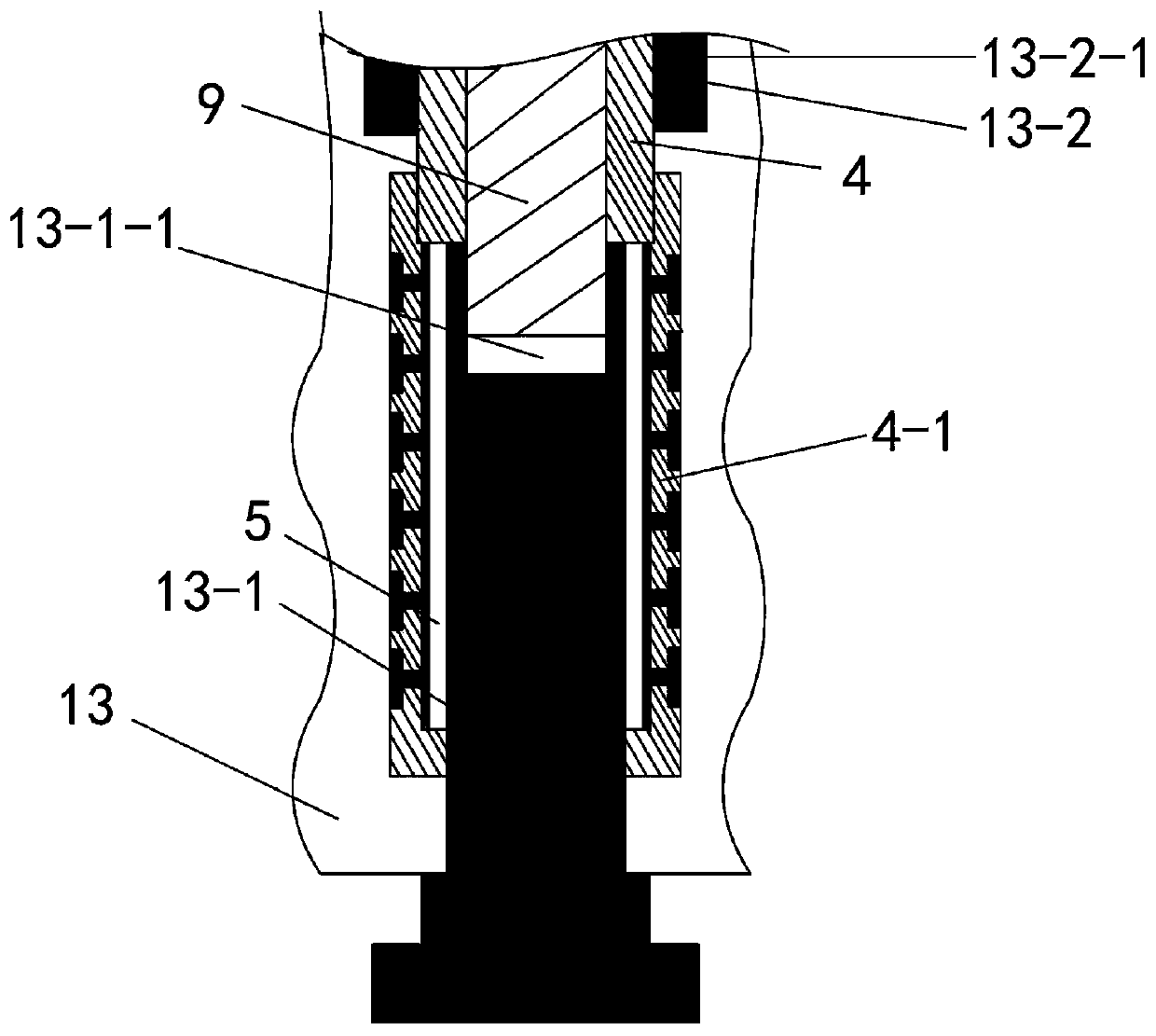

[0028] Such as Figure 1~3 As shown, a low-height, high-reliability high-voltage wire for gas, including a wire body 9, an insulating sheath 4, and a spark plug connecting sleeve. 1. High temperature resistant silicone sleeve 6, insulating layer 4-1 and heat dissipation hard sleeve 2; said compression silicone sleeve 3 is detachably distributed in said heat conduction hard tube 5, of course, this embodiment also uses high temperature resistant silicone material; The high-temperature-resistant silicone sleeve 6 includes a bottom sleeve 6-1 and a "T"-shaped heat conduction bump 6-2; the thickness of the bottom sleeve 6-1 is between 0.5 and 1.5mm; the bottom sleeve 6 -1 is distributed with several "T" shaped heat conduction bumps 6-2; the tops of the "T" shape heat conduction bumps 6-2 are distributed along the axial direction of the bottom sleeve 6-1. The bottom sleeve 6-1 is set on the outside of the heat-conducting hard tube 5; the insulating layer 4-1 is covered on the high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com