Preparation method of oleanolic acid slow-releasednano-microcapsule

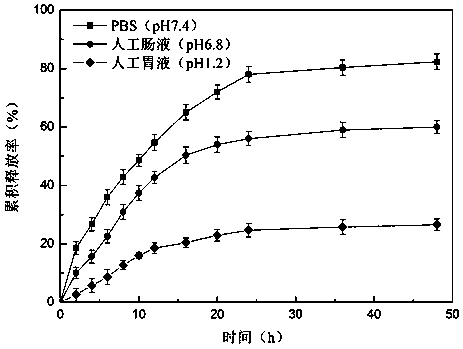

A technology of nano-microcapsules and oleanolic acid, which is applied in the direction of nano-capsules, capsule delivery, medical preparations of non-active ingredients, etc., and can solve problems such as low bioavailability, poor intestinal permeability, and poor water solubility , to achieve the effect of strong practicability, simple preparation method and high efficiency of controlled release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of oleanolic acid slow-release nano-microcapsules, comprising the following steps:

[0028] (1) Prepare the amphiphilic polymer wall material of sustained-release nano-microcapsules, the 1000Da chitosan oligosaccharide with a weight part of 19.630-21.442, the deoxycholic acid with a weight percentage of 58.890-64.325 and a weight percentage of 15%-20% The 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) and N-hydroxysuccinimide (NHS) were dispersed in organic solvents, and chitosan and The mass ratio of deoxycholic acid is 1:3 to 1:5. After fully reacting with magnetic stirring, it is dialyzed in distilled water (1000Da dialysis bag), and freeze-dried to obtain the amphiphile of slow-release nano-microcapsules of deoxycholic acid modified chitosan oligosaccharides. permanent polymer wall material.

[0029] (2) Dissolve oleanolic acid with a weight part of 14.233-21.480 in an organic solvent to prepare a dispersion of oleanolic acid...

Embodiment 2

[0032] A preparation method of oleanolic acid slow-release nano-microcapsules, comprising the following steps:

[0033] (1) Prepare the amphiphilic polymer wall material of sustained-release nano-microcapsules, and the carboxymethyl chitosan of 80.839-83.641 parts by weight and the 1-(3-dimethylamino group of 15%-20% by weight Propyl)-3-ethylcarbodiimide hydrochloride (EDC) and N-hydroxysuccinimide (NHS) were respectively dispersed in organic solvents, and after fully reacting with magnetic stirring, placed in distilled water for dialysis (1000Da dialysis bag ), freeze-dried to obtain the amphiphilic polymer wall material of the sustained-release nano-microcapsules of deoxycholic acid-modified chitosan oligosaccharides.

[0034] (2) Dissolve oleanolic acid in parts by weight of 16.359-19.161 in an organic solvent to prepare a dispersion of oleanolic acid with a volume mass concentration of 1-2 mg / mL, and disperse it in the volume mass mass prepared in step (1). In the wall ma...

Embodiment 3

[0037] A preparation method of oleanolic acid slow-release nano-microcapsules, comprising the following steps:

[0038](1) Prepare the amphiphilic polymer wall material of the slow-release nano-microcapsules, the 3000Da chitosan oligosaccharide with the weight part of 18.614-20.210, the deoxycholic acid with the weight part of 55.842-60.629 and the weight percentage of 15%-20% The 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) and N-hydroxysuccinimide (NHS) were dispersed in organic solvents, and chitosan and The mass ratio of deoxycholic acid is 1:3 to 1:5. After fully reacting with magnetic stirring, it is dialyzed in distilled water (1000Da dialysis bag), and freeze-dried to obtain the amphiphile of slow-release nano-microcapsules of deoxycholic acid modified chitosan oligosaccharides. permanent polymer wall material.

[0039] (2) Dissolve oleanolic acid in parts by weight of 19.161 - 24.544 in an organic solvent to prepare a dispersion of oleanolic acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com