Mechanical arm system and method for machining complicated spherical curved face shell

A spherical curved surface, robotic arm technology, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve problems such as low precision, complexity, and large workload, and achieve high precision, strong initiative, and real-time performance. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

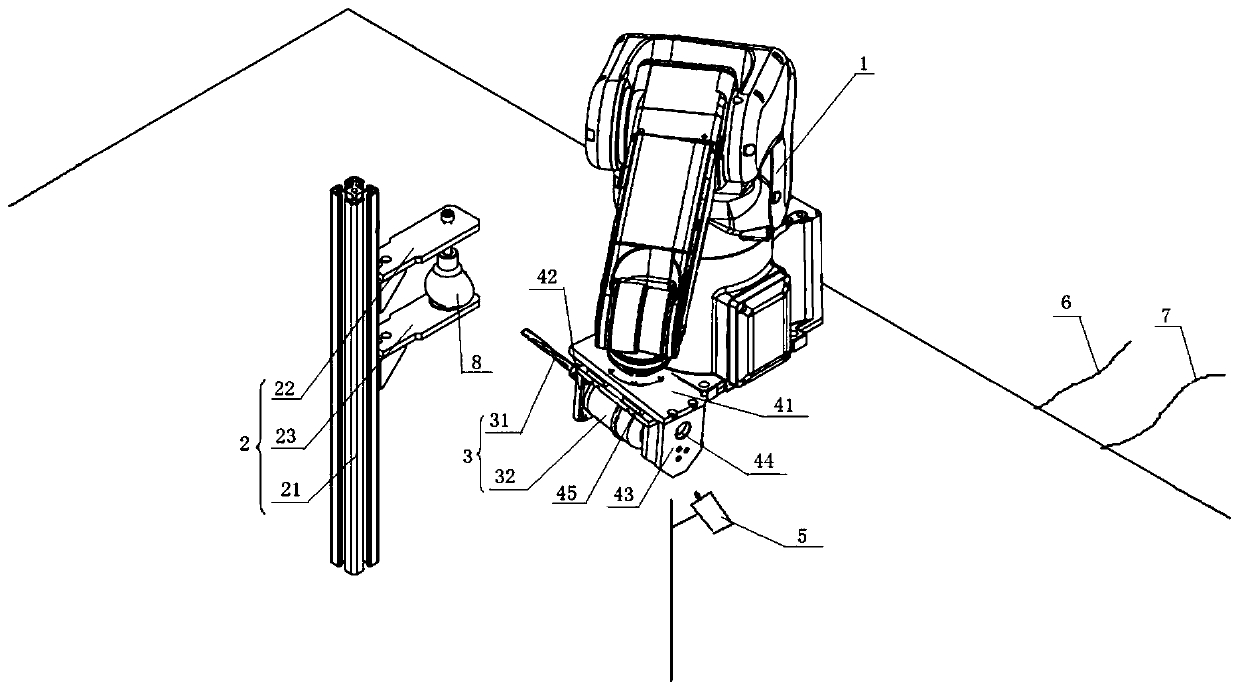

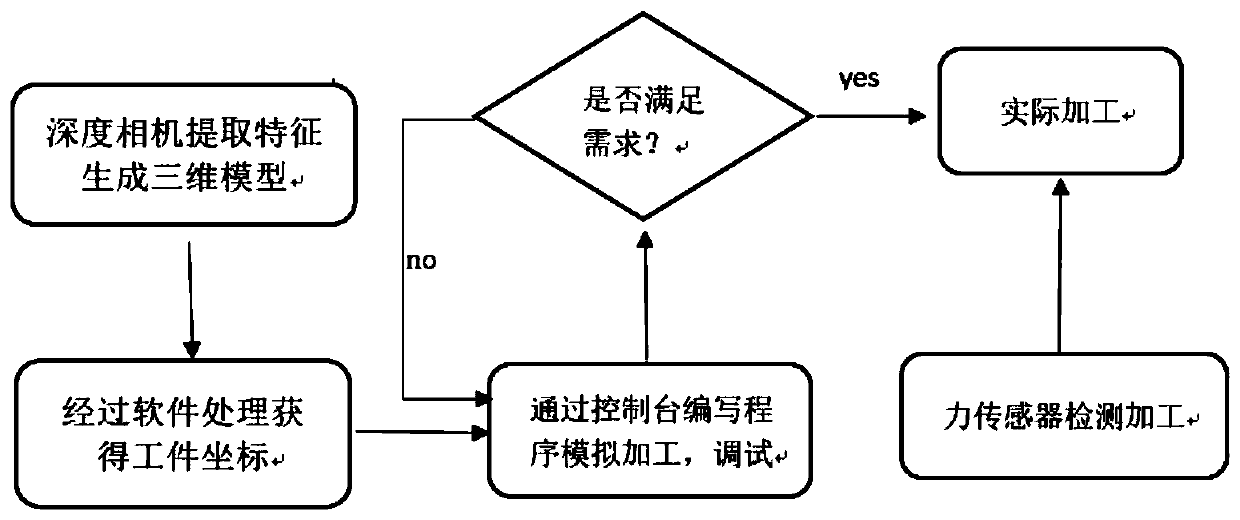

[0030] A robotic arm system for machining complex spherical curved shells, such as figure 1 As shown, it includes a mechanical arm 1, a working support 2, a processing device 3, a workpiece image acquisition device and a console, wherein: the working support 2 is arranged within the working range of the mechanical arm 1 for fixing the workpiece 8; the processing device 3 passes through the clamp body Connected to the end of the mechanical arm 1, the processing device 3 has a processing tool 31, and the clamp body is provided with a force sensor 44 for sensing the magnitude of the force between the processing tool 31 and the workpiece 8 in the process of processing; the workpiece image acquisition device is used to acquire The three-dimensional image of the workpiece 8, and obtain the coordinate information characteristics of the workpiece 8; the console is used to receive the coordinate information characteristic data and force sensor data of the workpiece 8, and control the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com