Preparation method of nitrogen-doped three-dimensional porous carbon loaded with nano cobalt and application thereof in lithium sulfur batteries

A three-dimensional porous, nano-cobalt technology, applied in battery electrodes, nanotechnology, nanotechnology, etc., can solve the problems of lack of mesoporous, macroporous structure, low yield, unfavorable high energy density and high performance lithium-sulfur battery, etc. The effect of increasing the number of mesopores and increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

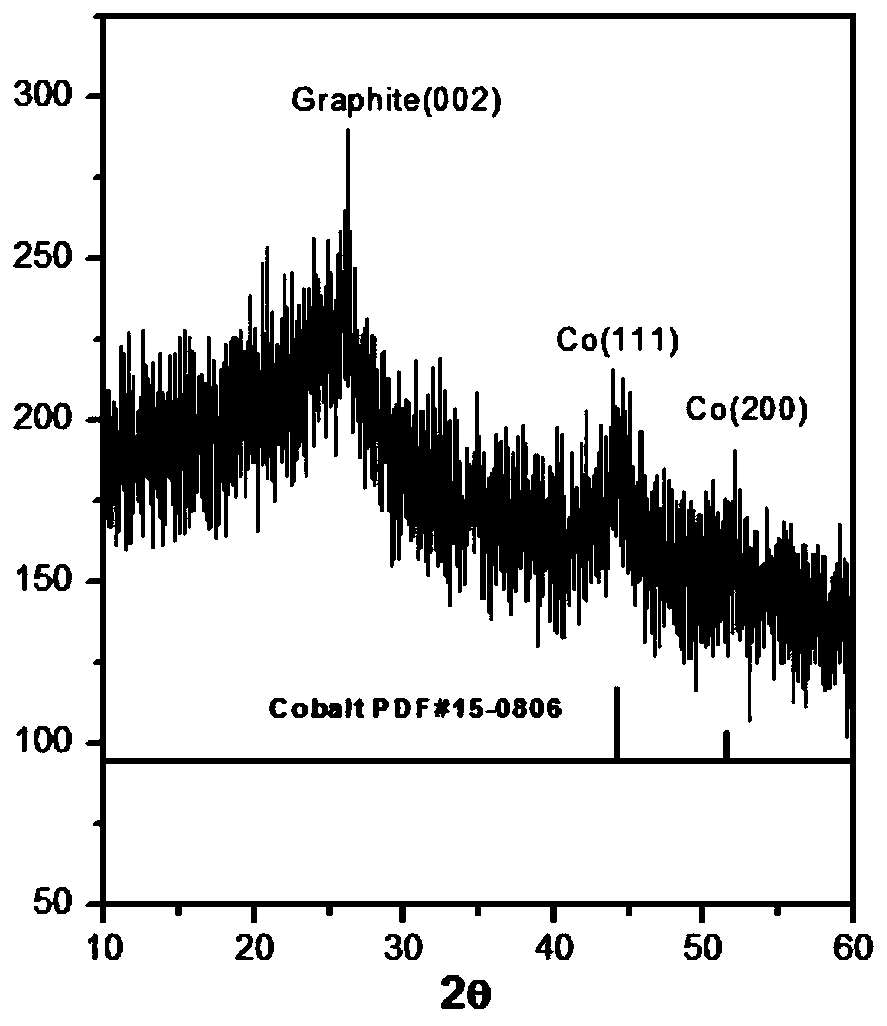

[0025] The present invention proposes a preparation method of nitrogen-doped three-dimensional porous carbon supported by nano-cobalt, comprising the following steps:

[0026] (1) adding inorganic nanospheres to methanol for ultrasonic dispersion, then adding cobalt salt and stirring to dissolve, then adding 2-methylimidazole methanol solution to obtain a precursor solution;

[0027] Preferably, the concentration of inorganic nanospheres in the precursor solution is 5-50 g / L; the concentration of cobalt salt in the precursor solution is 0.01-0.1 mol / L; the cobalt salt and 2-methylimidazole The molar ratio of 1: (0.5 ~ 10) to form the ZIF67 precursor. The number of mesopores and macropores is controlled by controlling the amount of cobalt salt and inorganic nanospheres added, and the wall thickness of the three-dimensional porous carbon in the product is controlled by controlling the ratio of cobalt salt and inorganic nanospheres.

[0028] Preferably, the inorganic nanospheres...

Embodiment 1

[0041] This embodiment provides a method for preparing nano-cobalt-supported nitrogen-doped three-dimensional porous carbon, comprising the following steps:

[0042] (1) Add 15ml tetraethyl orthosilicate to a mixed solvent composed of 10ml ammonia water, 200ml ethanol, and 100ml water under magnetic stirring, stir at 30°C for 2h, filter, wash and dry the resulting product to obtain a particle size of 300nm Silica nanosphere powder left and right.

[0043] (2) get the 3.0g white SiO obtained in step (1) 2 The nanosphere powder was ultrasonically dispersed in 100ml methanol for 2h, and then 0.8g Co(NO 3 ) 2 Stir to dissolve, then add 100ml of methanol solution containing 1.0g of 2-methylimidazole to obtain a precursor solution.

[0044] (3) The precursor solution was stirred and reacted at 30°C for 1 hour, and then stirred and evaporated to dryness at 80°C to obtain gray-purple precursor powder;

[0045] (4) Place the gray-purple precursor powder in a tube furnace under high...

Embodiment 2

[0054] This embodiment provides a method for preparing nano-cobalt-supported nitrogen-doped three-dimensional porous carbon, comprising the following steps:

[0055] (1) Add 15ml of tetraethyl orthosilicate to a mixed solvent consisting of 5ml of ammonia water, 200ml of ethanol, and 20ml of water under magnetic stirring, stir at 30°C for 2 hours, filter, wash and dry the resulting product to obtain a particle size of 100nm Silica nanosphere powder left and right.

[0056] (2) get the SiO of 3.0g that step (1) obtains 2 The nanosphere powder was ultrasonically dispersed in 100ml methanol for 2h, and then 0.8g Co(NO 3 ) 2 Stir to dissolve, and then add 100 ml of methanol solution containing 1.0 g of 2-methylimidazole to obtain a precursor reaction solution.

[0057] (3) The precursor reaction solution obtained in step (2) was stirred and reacted at 40°C for 0.5h, and then stirred and evaporated to dryness at 90°C to obtain gray-purple precursor powder;

[0058] (4) Place the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com