Structured packing suitable for mosaic rotating packed bed and application thereof

A technology of rotating packed bed and structured packing, applied in chemical/physical/physical-chemical fixed reactors, chemical/physical/physical-chemical processes, chemical instruments and methods, etc., can solve the problem of increasing liquid dispersion atomization and residence time, The enhancement effect of gas phase mass transfer coefficient is not obvious, etc., to achieve the effect of strengthening the gas film control process, uniform distribution of gas and liquid channels, and light packing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

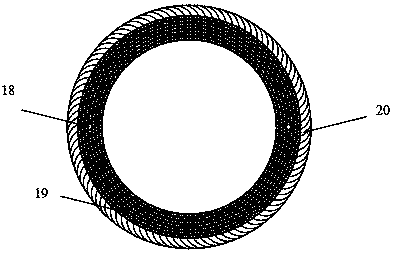

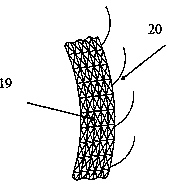

[0034] Such as Figure 1~6 As shown, a structured packing suitable for a mosaic rotating packed bed is composed of a regular wire mesh structure 19 and a fin structure 20; .

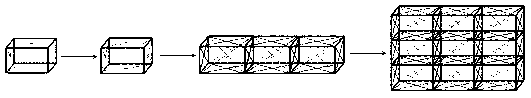

[0035] The three-dimensional configuration of the regular screen structure is as follows: a plurality of layers of rings tangent to the wire mesh are arranged in the radial direction, each layer of wire mesh is a ring surrounded by several cubes, and the cubes face diagonal lines, body The diagonals are connected to each other to form a triangle in three-dimensional space, which makes full use of the stability of the triangle, and the regular gas-liquid circulation channel improves the utilization rate of the packing; in order to ensure a uniform gas-liquid circulation channel, the adjacent wire mesh Layers are staggered by 15-45 degrees, increasing the chances of the liquid colliding with the packing.

[0036] The three-dimensional configuration of the fin structure is as follows: arcs formed by wire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Arc length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com