Energy-saving environment-protecting material sucking and drying all-in-one machine

An energy-saving and environmentally-friendly integrated machine technology, applied in the field of injection molding, can solve the problems of high investment and production costs, easy blockage of feeding equipment, and large space occupation, and achieve fast drying speed, remarkable energy-saving effect of equipment, and slow fan speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

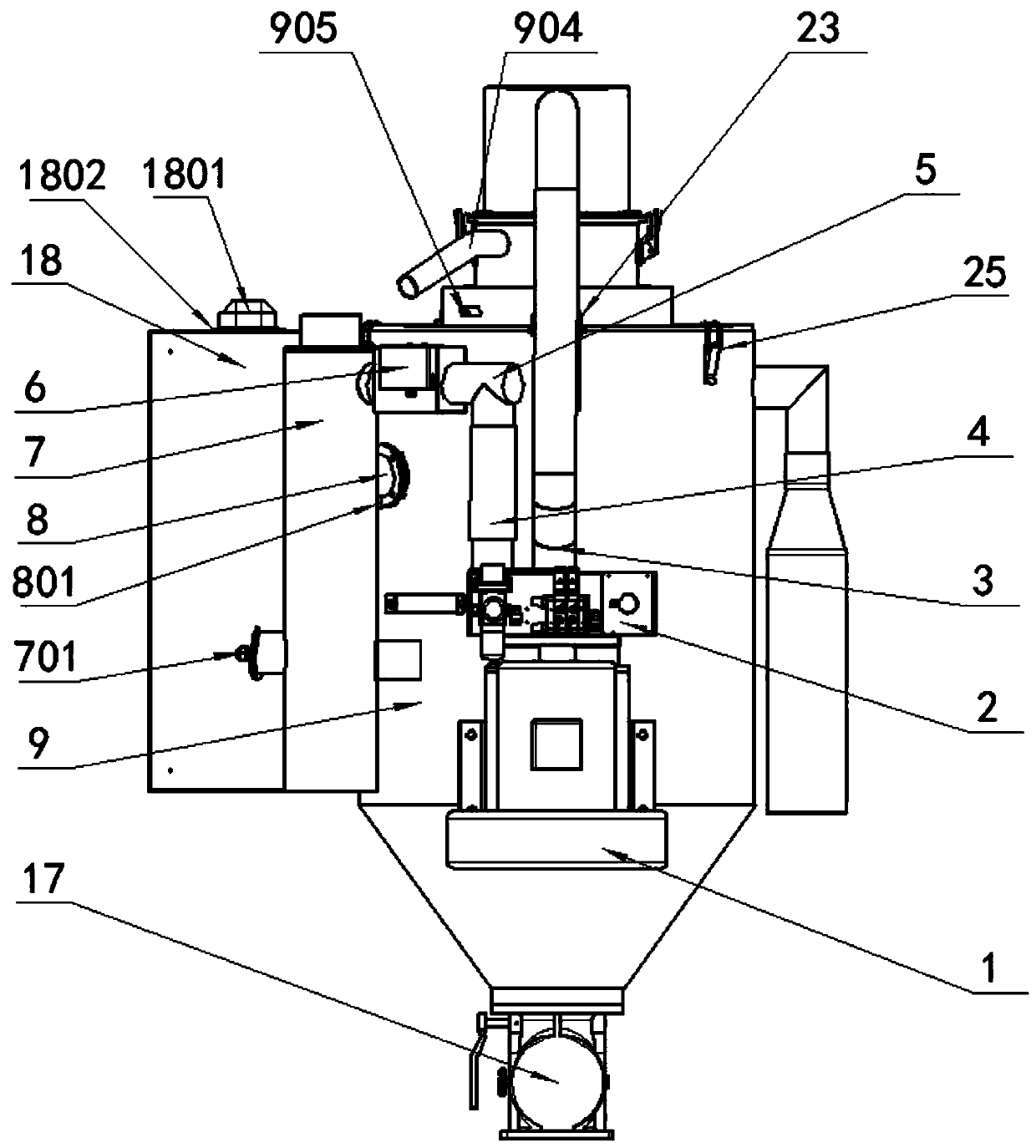

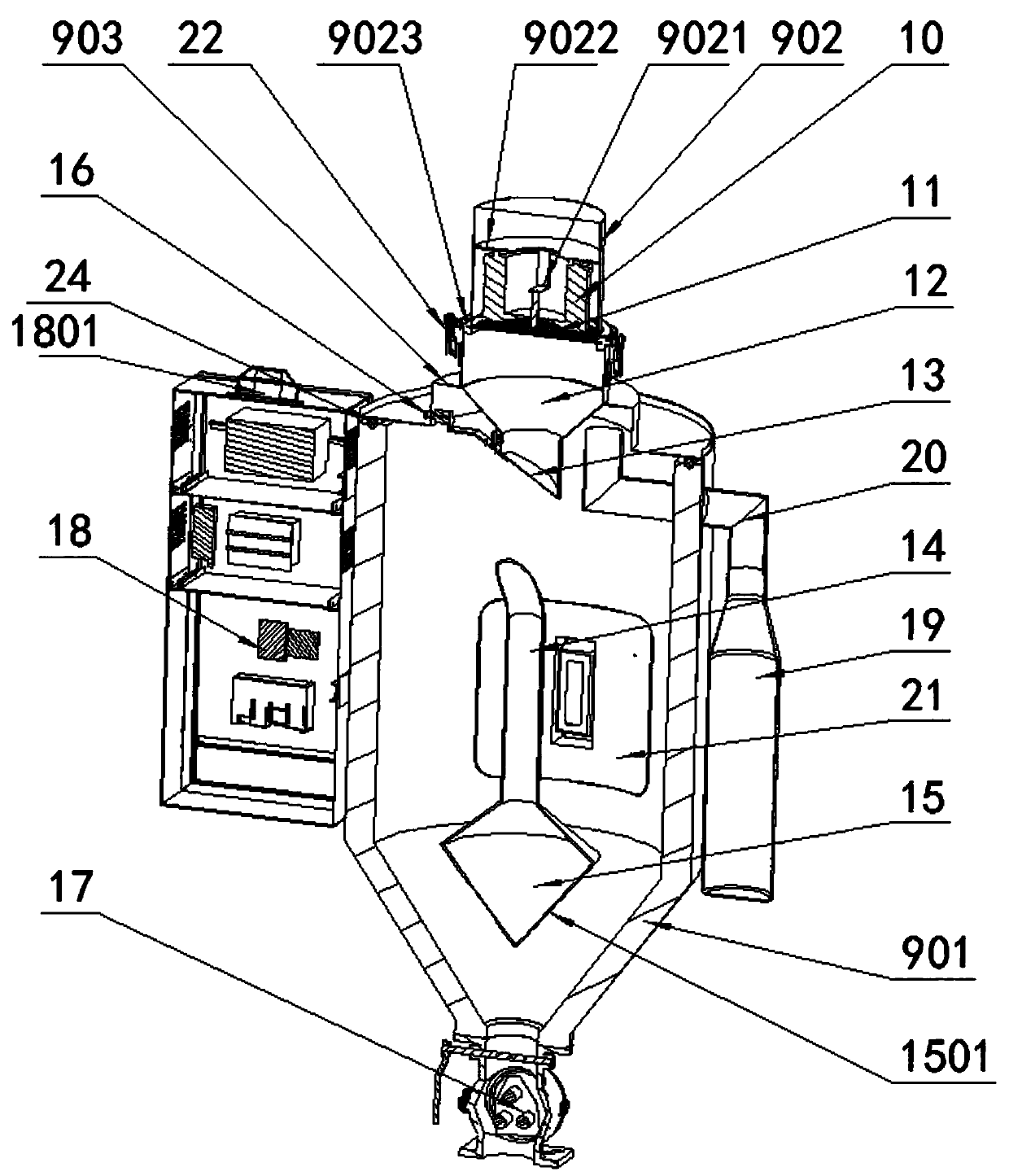

[0055] 4. See Figure 1 to Figure 4 , an energy-saving and environmentally friendly suction and dry material integrated machine, comprising a barrel main body (9), a fan (1), a pulse switching exhaust mechanism (2), a heater (7), a feeding device (17), and a barrel main body The electrical control system (18) installed on the outer side and components such as connecting pipe fittings are formed. The barrel main body (9) is divided into four parts: the main body shell (901), the hopper top cover (902), the material hopper (12), and the barrel upper cover (903). The main body shell (901) has a double-layer stainless steel structure. A fan (1) is fixedly connected to the lower part of the cylindrical side wall, and the two vents on the top of the fan (1) are connected with a pulsating switching exhaust device (2), and the upper end surface of the pulsating switching exhaust device (2) is respectively connected with a The first air duct (3) and the second air duct (4), the upper ...

Embodiment 2

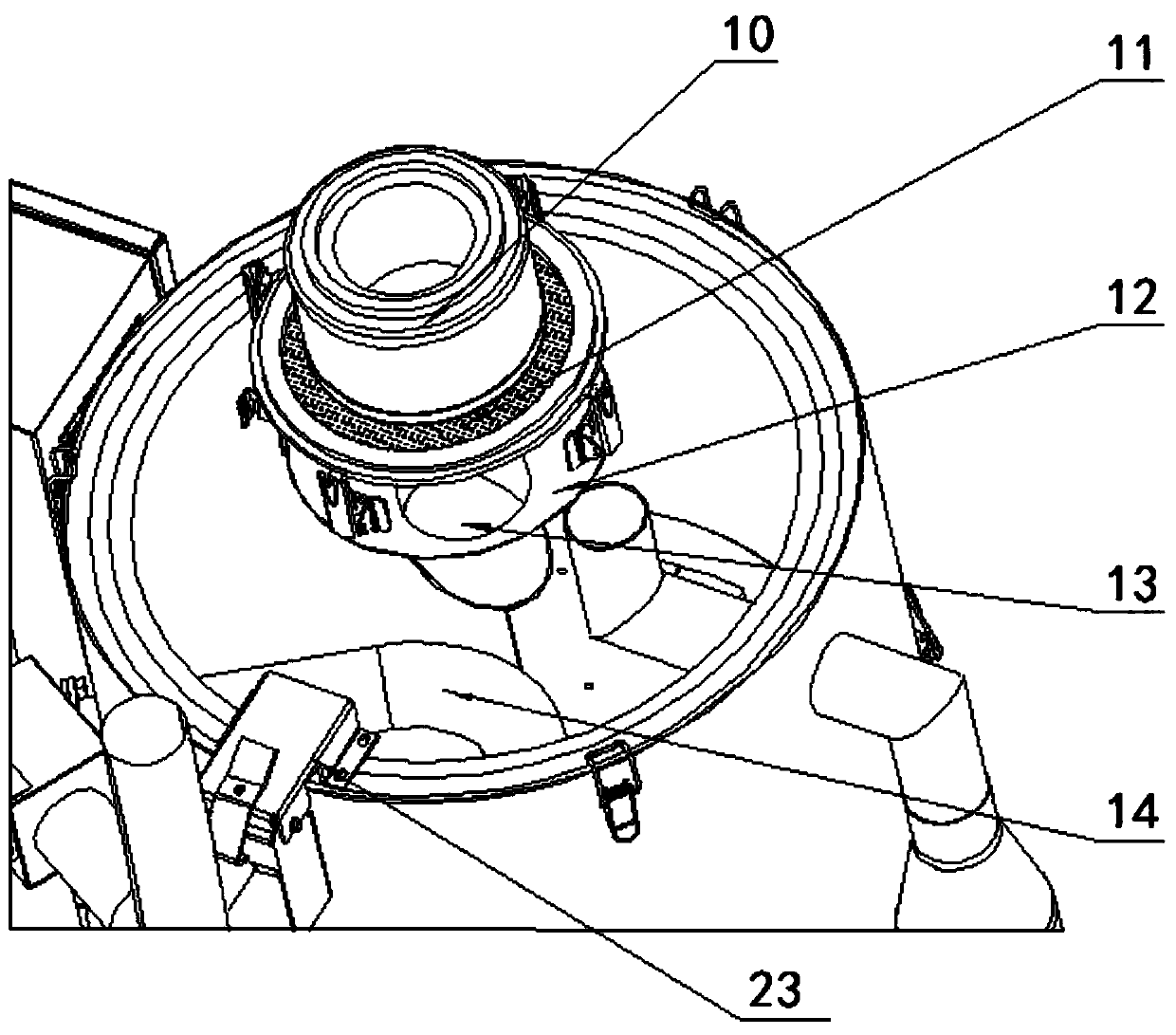

[0057] see image 3 and 4 , the hopper top cover (902) is connected with the material hopper (12) through the top cover buckle (22), and the mating surface is sealed by a coarse filter sealing ring (9023) fixed with a stainless steel coarse filter (11), and the hopper top cover (902) is horizontally welded with a ring plate (9022) close to the upper inner wall, and the ring plate (9022) is welded with a fine filter holder (9021) for fixing the filter paper fine filter screen (10), and the ring plate (9022 ) lower end surface is sealed with a filter paper fine filter screen (10) with a cylindrical structure through the fine filter fixing frame (9021), so that the material will not flow from the top cover of the hopper under the action of the stainless steel coarse filter screen 11 and the filter paper fine screen screen 10. flow out. At the same time, the main body shell (901) is fixedly connected with the barrel upper cover (903) through the upper cover buckle (25), and the ...

Embodiment 3

[0059] see figure 1 and 3 A return air temperature and humidity detection sensor (905) and a material level detection switch (16) are arranged on the cylindrical side wall of the barrel upper cover (903) close to the feed pipe (904), and the lower end of the material hopper (12) is attached to the inclined surface There is a material baffle (13), and the material baffle (13) is connected to the output end of the material level detection switch (16). (14) Through the main body casing (901) and communicate with the fourth air pipe (8), and the lower end surface of the fifth air pipe (14) communicates with a heat dissipation conical pipe (15), on the heat dissipation tapered pipe (15) There are a plurality of conical tube microholes (1501) penetrating through the side surface wall of the heat dissipation conical tube (15), so that the material level detection switch 16 controls the material baffle plate 13 to control the material, so as to facilitate the discharge of the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com