Capsule type underwater toilet blowdown device

A technology of underwater toilet and sewage discharge device, which is applied in the direction of water supply device, engine room flushing device, and sewage discharge, etc. It can solve the problems that the sewage discharge device of underwater toilet cannot deodorize, the sewage discharge pressure cannot be adjusted, and the generation of howling and air bubbles can achieve sewage discharge. Good effect, improved reliability and service life, stable pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

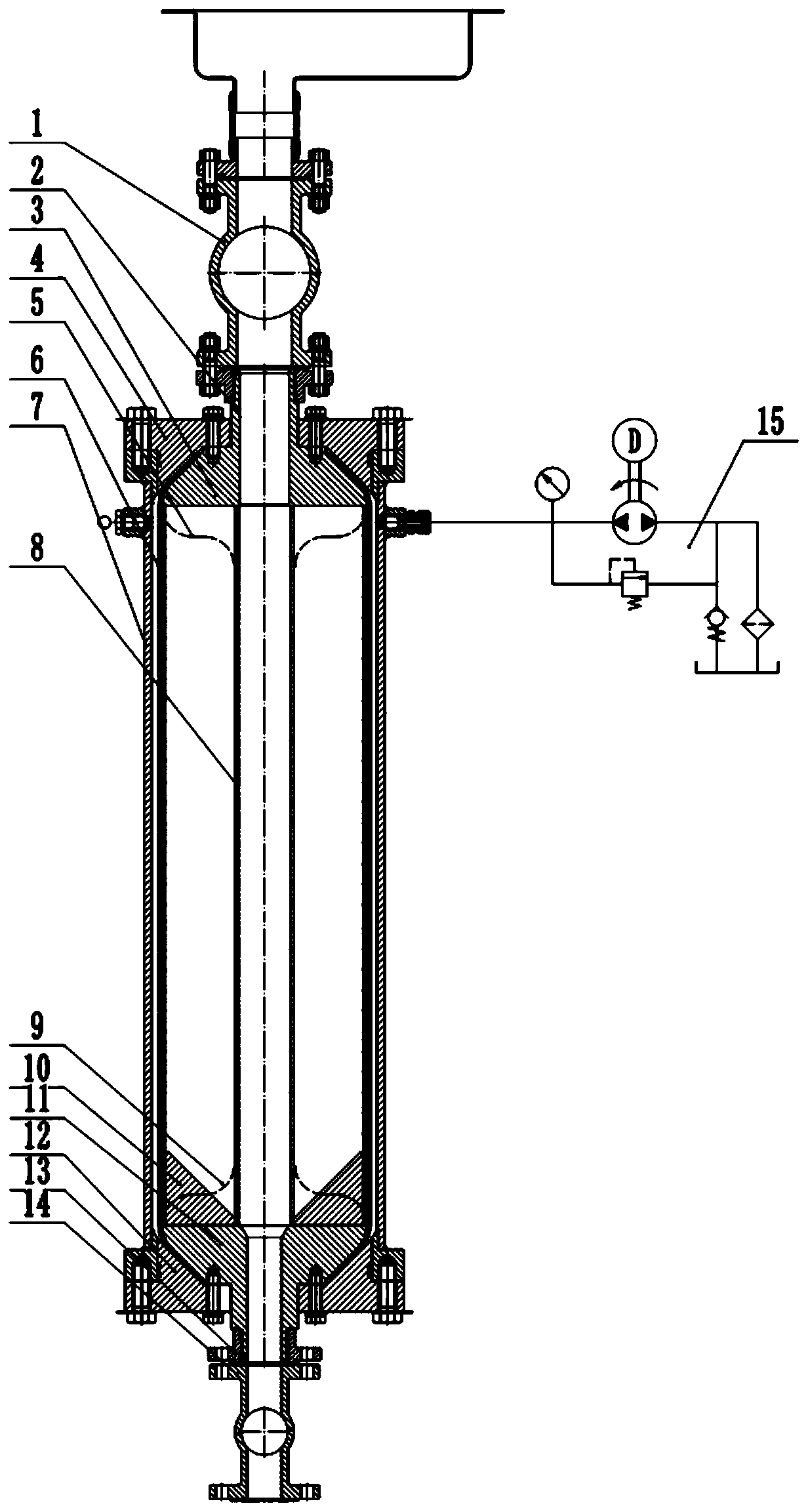

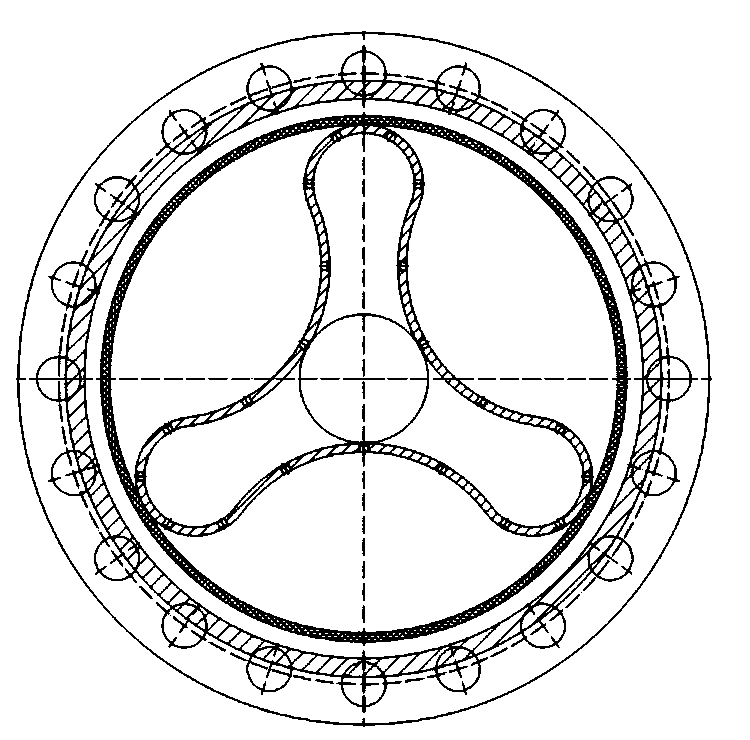

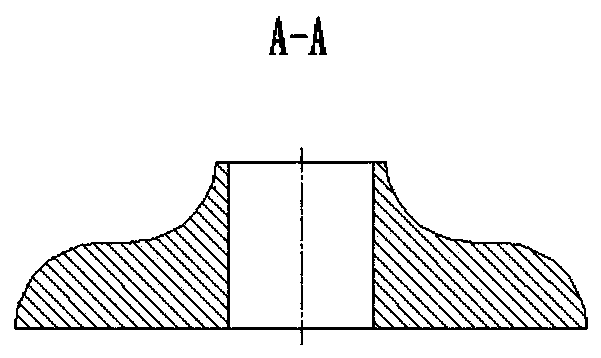

[0022] Such as figure 1 , 2 As shown, the present embodiment provides a capsule type underwater toilet sewage discharge device, including a sewage inlet pipeline, a storage container 7, a capsule 6, a screen bushing 8, a sewage drainage pipeline and a pumping station 15, and the inner cavity of the storage container is provided There is a capsule 6, the two ends of the capsule 6 are respectively sealed and pressed on the two ends of the storage container through the inlet gland 3 and the outlet gland 11, and the inlet gland 3 and the outlet gland 11 are respectively connected to the sewage pipe and the sewage The pipeline is connected, and a screen bushing 8 is provided in the capsule, and its two ends are respectively connected with the inlet gland 3 and the outlet gland 11. The pump station 15 is provided with a pipeline and the storage container 7 is connected. The pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com