Method for controlling viscosity of iron oxide yellow with amino acid crystal form control agent

A technology of crystal form control agent and iron oxide yellow, which is applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., can solve the problems of effect damage, damage to the shape of iron oxide yellow pigment particles, unfavorable production, etc., and reduce the aspect ratio , reduce viscosity, reduce the effect of bifurcation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

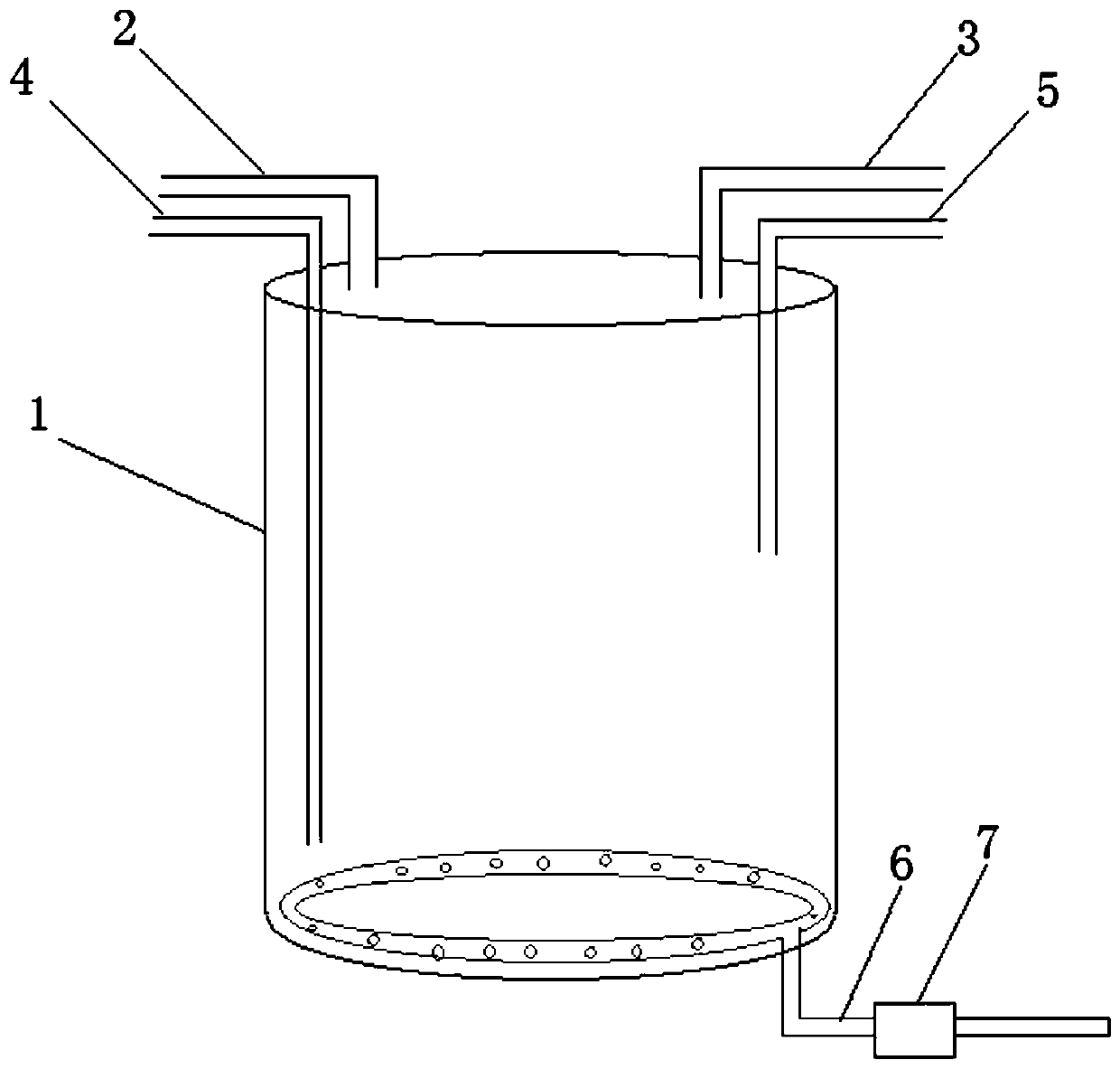

Image

Examples

Embodiment 1

[0028] The preparation method of iron oxide yellow, the method comprises the steps:

[0029] 1) Seed crystal production:

[0030] A. Raw material configuration: 50m 3 Add ferrous sulfate solution with a concentration of 1.5mol / L into the stainless steel reaction barrel, and then add a volume of 7m 3 Sodium hydroxide solution with a concentration of 2.5mol / L, while controlling the reaction temperature at 25-35°C;

[0031] B: Air volume control: Control the total reaction time to 14-17h, and pass air to the bottom of the reaction solution in the first 5-7 hours, and the air volume is controlled at 230m 3 / h, after 7-10h, the air volume is controlled at 460m 3 / h; The final material of the reaction is stored separately as a seed crystal;

[0032] 2) Add amino acid crystal form control agent to oxidize:

[0033] A: Put the prepared seed crystals into the reaction tank, then add a certain amount of water to dilute, control the ferrous content between 1.34mol / L and 1.52mol / L, a...

Embodiment 2

[0040] The preparation method of iron oxide yellow, the method comprises the steps:

[0041] 1) Seed crystal production:

[0042] A. Raw material configuration: 50m 3 Add ferrous sulfate solution with a concentration of 1.5mol / L into the stainless steel reaction barrel, and then add a volume of 7m 3Sodium hydroxide solution with a concentration of 2.5mol / L, while controlling the reaction temperature at 25-35°C;

[0043] B: Air volume control: Control the total reaction time to 14-17h, and pass air to the bottom of the reaction solution in the first 5-7 hours, and the air volume is controlled at 230m 3 / h, after 7-10h, the air volume is controlled at 460m 3 / h. The final material of the reaction is stored separately as a seed crystal;

[0044] 2) Add amino acid crystal form control agent to oxidize:

[0045] A: Put the prepared seed crystals into the reaction tank, then add a certain amount of water to dilute, control the ferrous content between 1.34mol / L and 1.52mol / L, a...

Embodiment 3

[0051] The preparation method of iron oxide yellow, the method comprises the steps:

[0052] 1) Seed crystal production:

[0053] A. Raw material configuration: 50m 3 Add ferrous sulfate solution with a concentration of 1.5mol / L into the stainless steel reaction barrel, and then add a volume of 7m 3 Sodium hydroxide solution with a concentration of 2.5mol / L, while controlling the reaction temperature at 25-35°C;

[0054] B: Air volume control: Control the total reaction time to 14-17h, and pass air to the bottom of the reaction solution in the first 5-7 hours, and the air volume is controlled at 230m 3 / h, after 7-10h, the air volume is controlled at 460m 3 / h. The final material of the reaction is stored separately as a seed crystal;

[0055] 2) Add amino acid crystal form control agent to oxidize:

[0056] A: Put the prepared seed crystals into the reaction tank, then add a certain amount of water to dilute, control the ferrous content between 1.34mol / L and 1.52mol / L, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com