Combined treatment method and system for food waste, excrement, illegal cooking oil and kitchen waste

A technology for catering waste and kitchen waste, which is applied in the direction of fuel oil system, chemical instruments and methods, filtration treatment, etc., can solve the problems such as difficult to control the stench, and the large area occupied by aerobic composting, so as to save labor, improve profitability, The effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

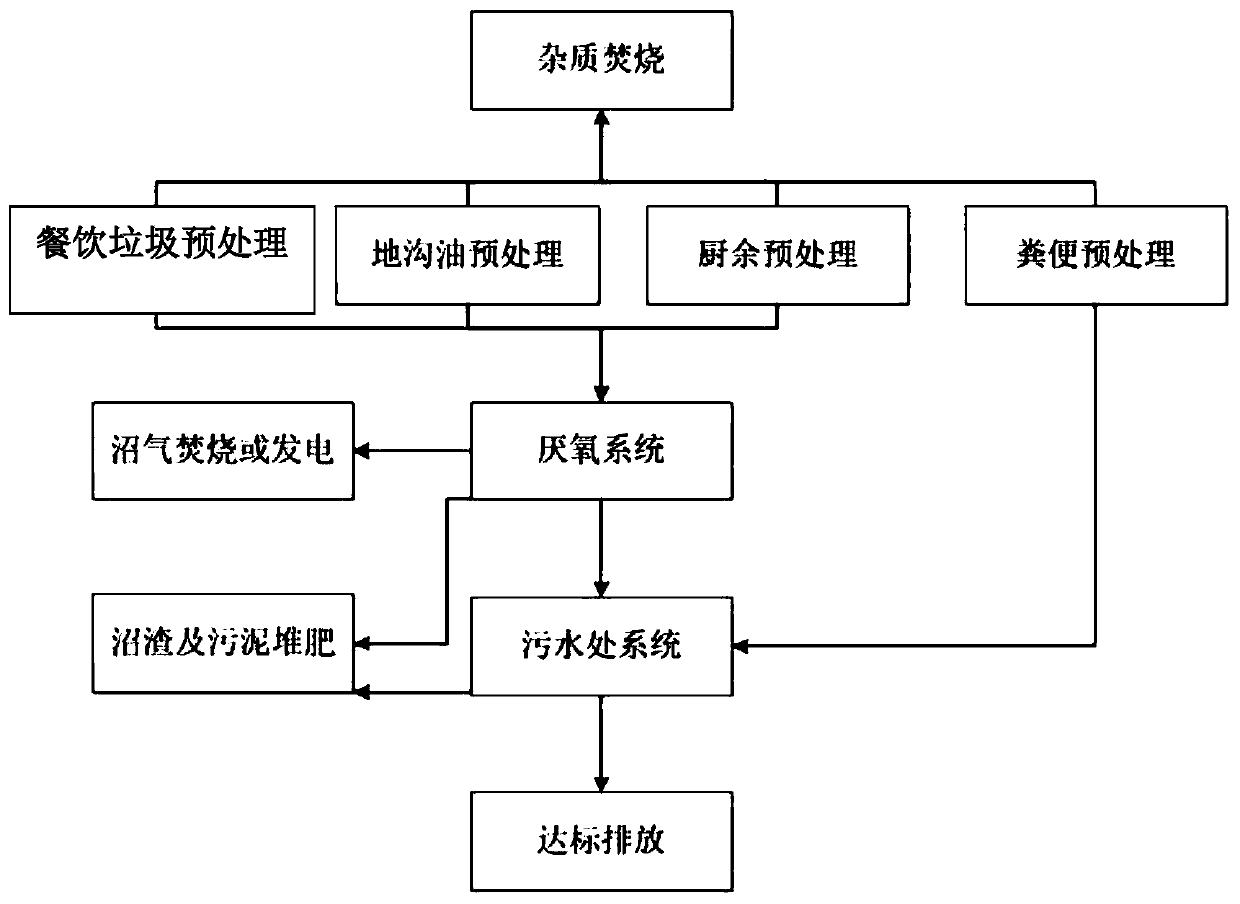

[0041] use as figure 1 The process shown is combined treatment of catering waste, feces, waste oil and kitchen waste, as follows:

[0042] 1. Pre-treat catering waste, gutter oil and kitchen waste, separate out inorganic debris, crush and make pulp, and separate oil, organic solids and concentrated water;

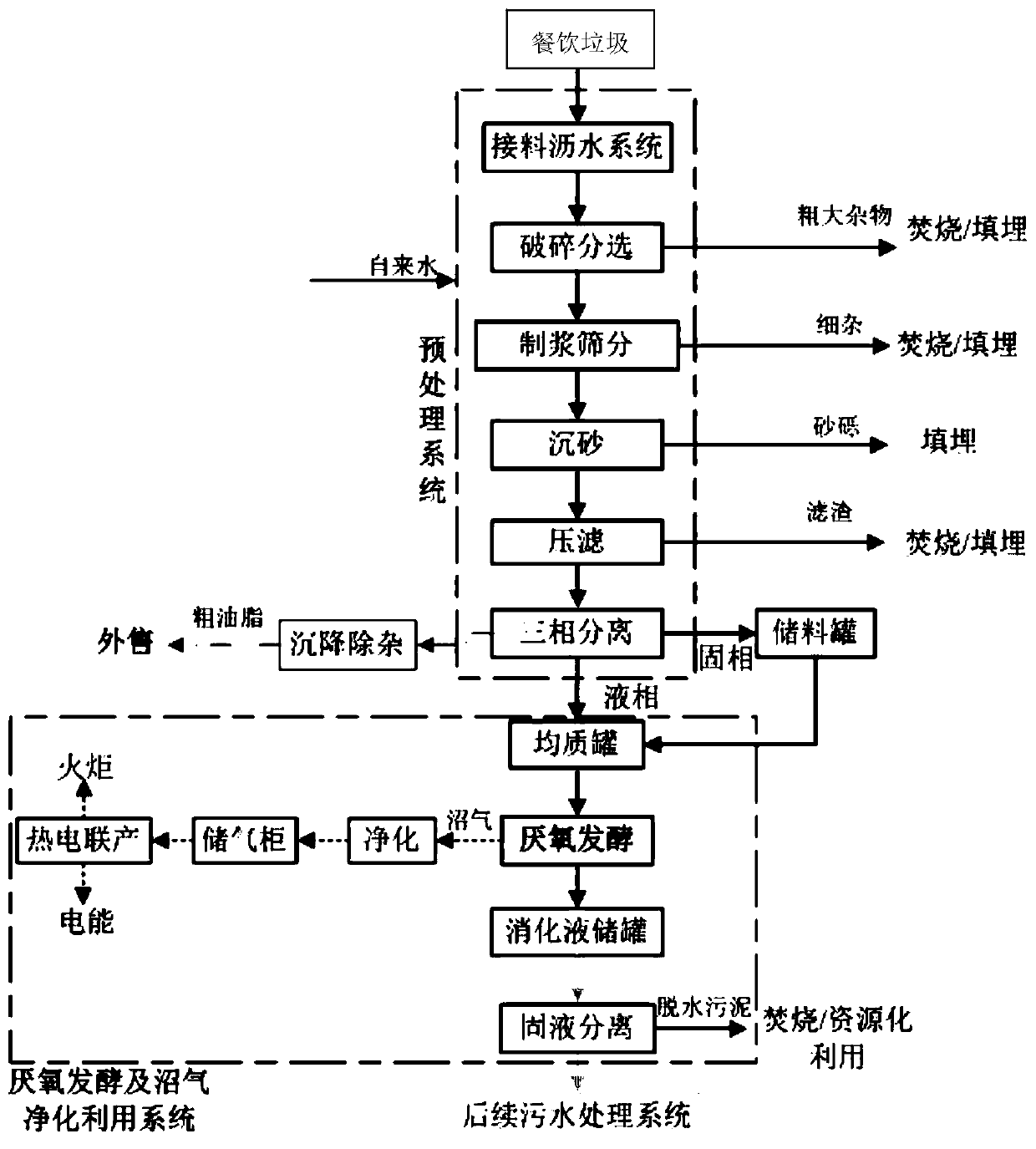

[0043] Such as figure 2 As shown, the pretreatment steps of food waste include sorting out organic solids and liquids from inorganic impurities, sending them into wet thermal hydrolysis and three-phase separation to obtain crude oil, organic solids and concentrated kitchen water;

[0044] The pretreatment of waste oil includes the use of basket filter frames to remove solids with a particle size of at least 8mm;

[0045] The pretreatment steps of the kitchen waste include removing iron and substances larger than 150 mm, and obtaining broken materials, which are organic solids.

[0046] 2. Anaerobic fermentation of organic solids and concentrated water to generate biogas...

Embodiment 2

[0058] Embodiment 2. A system for combined treatment of catering waste, feces, waste oil and kitchen waste

[0059] A combined treatment system for catering waste, feces, gutter oil and kitchen waste includes a pretreatment system, anaerobic fermentation system, solid-liquid separation system, sewage treatment system and deodorization system.

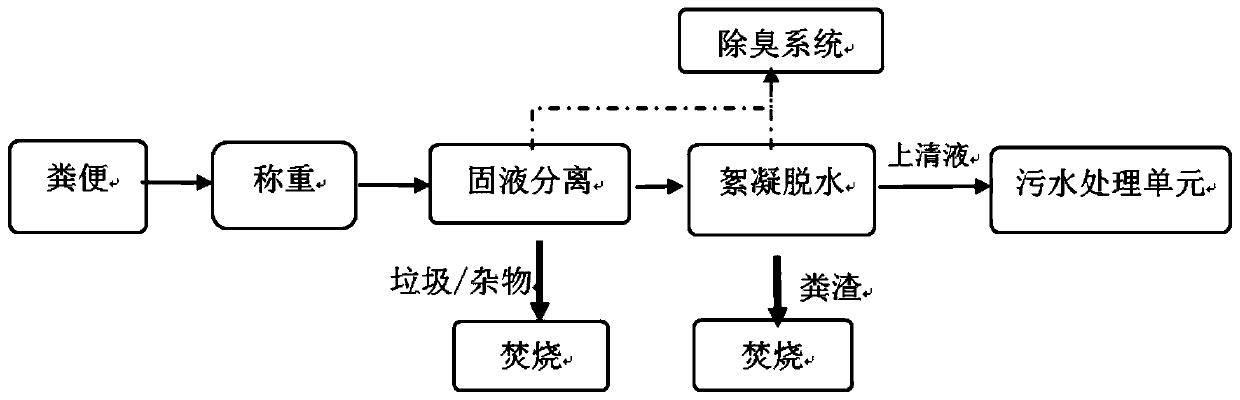

[0060] The pretreatment system is used to separate inorganic debris from food waste, waste oil and kitchen waste, and then crush and pulp, and to separate oil, organic solids and concentrated water; the anaerobic fermentation system is used to separate organic solids and concentrated water Perform anaerobic fermentation to generate biogas, and obtain biogas residue, biogas slurry and odor; solid-liquid separation system is used for solid-liquid separation of feces and biogas residue to obtain garbage, sundries and sewage; sewage treatment system is used for biogas slurry , Sewage is purified; the deodorization system is used to treat th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com