Shifter panelmaterialfor preventing light penetration interference and preparation method of panel

A shifter and panel technology, which is applied in the field of shifter panel materials and panel preparation, can solve the problems of increasing the number of molding molds, affecting the functionality and aesthetics of the shifter panel, and the difficulty in ensuring the uniformity of light transmission. Achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

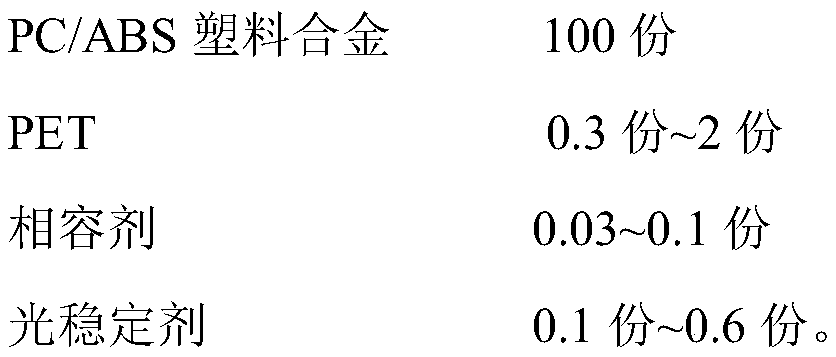

[0033] Embodiment 1 of a shifter panel material for preventing light penetration and interference according to the present invention is composed of the following components by weight:

[0034]

[0035] Among them, the PC / ABS plastic alloy adopts the material grade PC / ABS-2500 produced by Shanghai Huahe;

[0036] The material grade of PET produced by Mitsui Chemicals is J055, which is an amorphous product;

[0037] The compatibilizer adopts the product model SAG-002 produced by Jiayirong;

[0038] The light stabilizer is a product of BASF's model Tinuvin 5060.

[0039] The method for preparing a shifter panel using the above panel material includes the following steps:

[0040] (1) Dry PC / ABS plastic alloy at 90°C for 6hr, and PET at 120°C for 6hr;

[0041] (2) Add the dried PC / ABS plastic alloy, PET, light stabilizer and compatibilizer to the twin-screw extruder in proportion to blend, extrude and granulate, and the working temperature of the twin-screw extruder is 250°C...

Embodiment 2

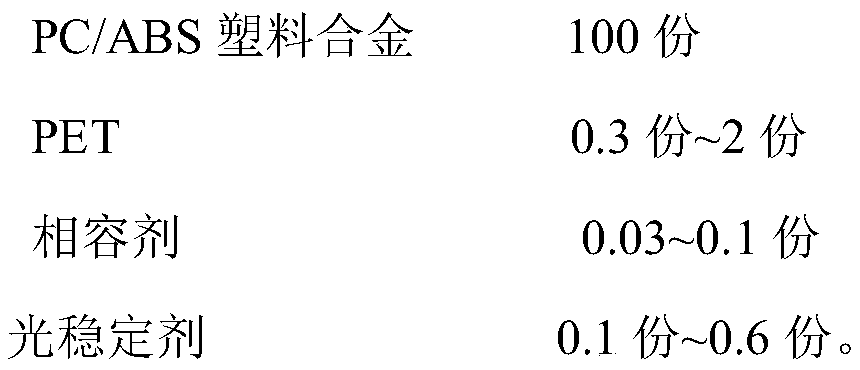

[0048] Embodiment 2 of a shifter panel material for preventing light penetration and interference of the present invention is composed of the following components by weight, and the material type of this embodiment is the same as that of Embodiment 1.

[0049]

[0050] The method for preparing a shifter panel using the above panel material includes the following steps:

[0051] (1) Dry PC / ABS plastic alloy at 95°C for 6hr, and PET at 120°C for 6hr;

[0052] (2) Add the dried PC / ABS plastic alloy, PET, light stabilizer and compatibilizer to the twin-screw extruder in proportion to blend, extrude and granulate, and the working temperature of the twin-screw extruder is 250°C ;

[0053] (3) The raw material particles prepared in step (2) are subjected to one injection molding in an injection molding machine to form a panel injection molded part, and in the injection molding machine, the working temperature of the injection mold is 230° C.;

[0054] (4) The outer surface of th...

Embodiment 3

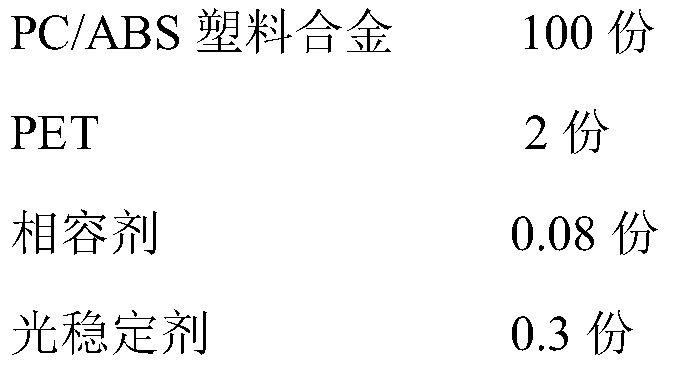

[0058] Embodiment 3 of a shifter panel material for preventing light penetration and interference according to the present invention is composed of the following components in parts by weight, and the material type of this embodiment is the same as that of Embodiment 1.

[0059]

[0060]

[0061] The method for preparing a shifter panel using the above panel material includes the following steps:

[0062] (1) Dry PC / ABS plastic alloy at 100°C for 6hr, and PET at 120°C for 6hr;

[0063](2) Add the dried PC / ABS plastic alloy, PET, light stabilizer and compatibilizer to the twin-screw extruder in proportion to blend, extrude and granulate, and the working temperature of the twin-screw extruder is 250°C ;

[0064] (3) The raw material particles prepared in step (2) are subjected to one injection molding in an injection molding machine to form a panel injection molded part, and in the injection molding machine, the working temperature of the injection mold is 230° C.;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com