A method for increasing the working voltage of dielectric thin film devices under strong electric field

A thin film device, working voltage technology, applied in the direction of fixed capacitor dielectrics, thin film/thick film capacitors, capacitors, etc., can solve the problems of inability to obtain large-area thin films and cannot be used in practical applications, and achieves suppression of thin film leakage current increase, The effect of suppressing leakage current and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The steps of this embodiment are as follows:

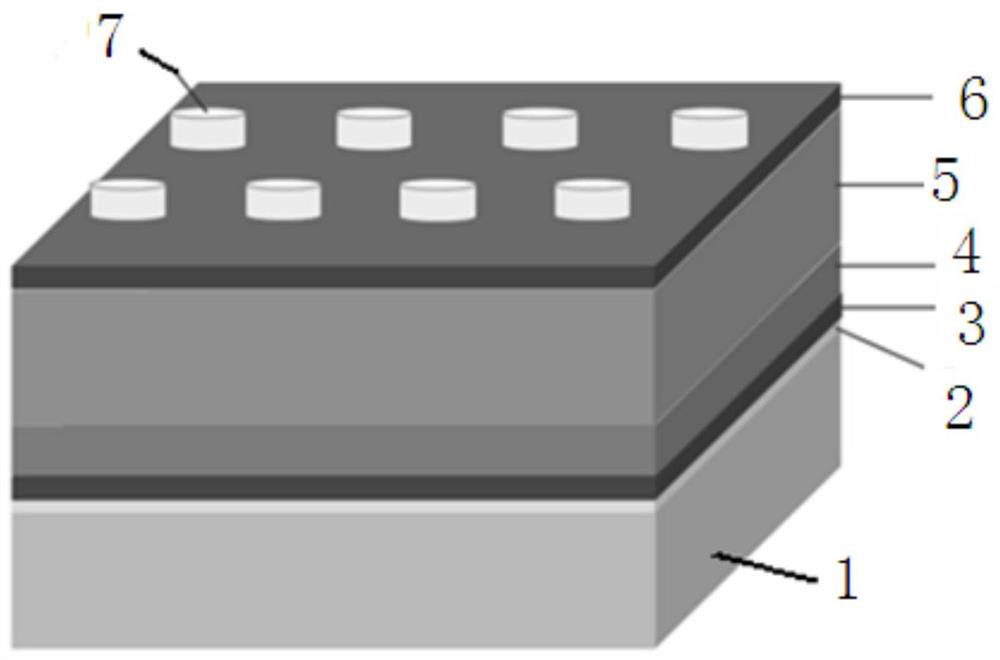

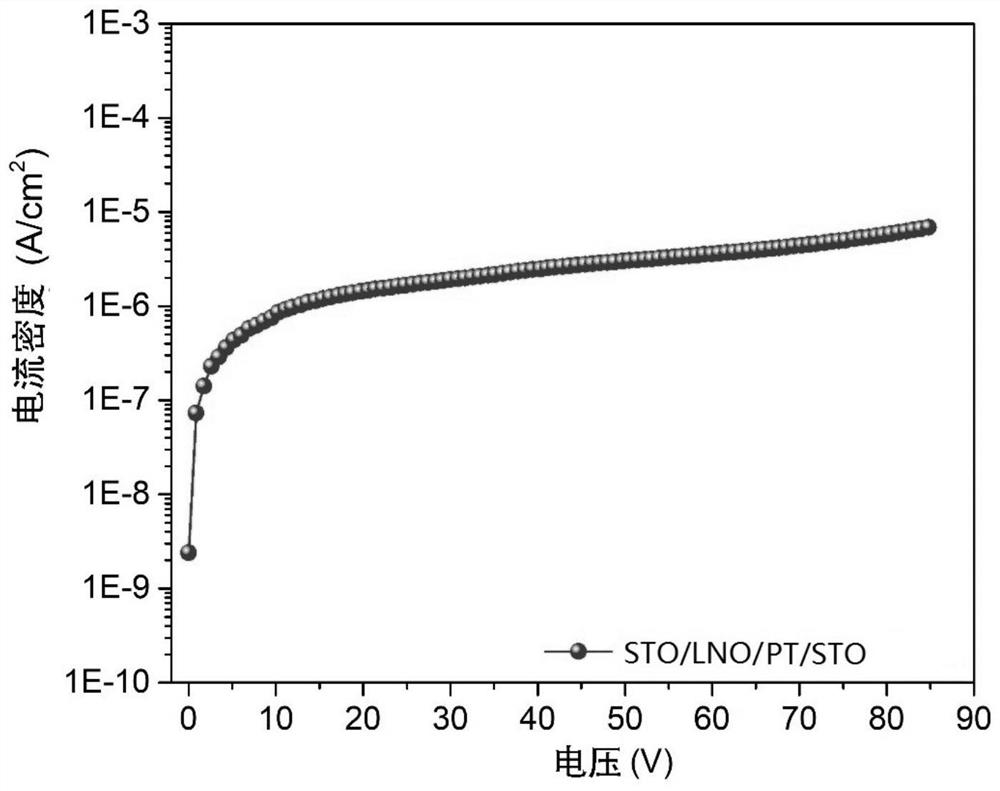

[0032] (1) On the Si substrate prepared with the first metal electrode Pt electrode, the first SrTiO with a thickness of 30 nm was sequentially prepared by radio frequency sputtering method (JGP-560C10 ultra-high vacuum multifunctional magnetron sputtering equipment) 3 layer, LaNiO with a thickness of 60nm 3 Transition layer, PbTiO with a thickness of 550nm 3 thin film, second SrTiO with a thickness of 30 nm 3 layer; preparation of the first SrTiO 3 The process parameters of the layer are: air pressure 2Pa, power 40W, substrate temperature 550°C, sputtering time 15min, Ar:O 2 =40:10 (volume ratio); prepare LaNiO 3 The process parameters of the transition layer are: air pressure 2Pa, power 40W, substrate temperature 550°C, sputtering time 30min, Ar:O 2=40:10 (volume ratio); prepare PbTiO 3 The process parameters of the film are: air pressure 2Pa, power 50W, substrate temperature 550°C, sputtering time 180min, Ar:O 2 =...

Embodiment 2

[0043] The steps of this embodiment are as follows:

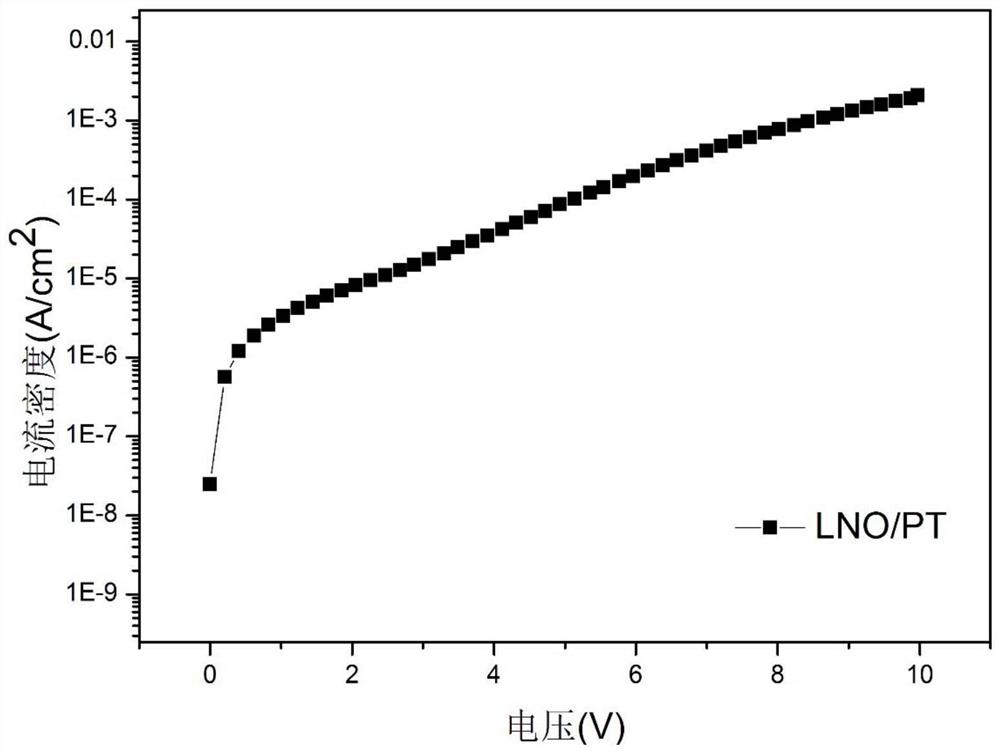

[0044] (1) On the Si substrate prepared with the first metal electrode Pt electrode, the first SrTiO with a thickness of 10 nm was sequentially prepared by radio frequency sputtering method (JGP-560C10 ultra-high vacuum multifunctional magnetron sputtering equipment) 3 layer, LaNiO with a thickness of 60nm 3 Transition layer, Pb with a thickness of 800nm 0.52 Zr 0.48 TiO 3 Thin film, second SrTiO with a thickness of 10 nm 3 layer; preparation of the first SrTiO 3 The process parameters of the layer are: air pressure 2Pa, power 40W, substrate temperature 550°C, sputtering time 6min, Ar:O 2 =40:10 (volume ratio); prepare LaNiO 3 The process parameters of the transition layer are: air pressure 2Pa, power 40W, substrate temperature 550°C, sputtering time 30min, Ar:O 2 =40:10 (volume ratio); prepare Pb 0.52 Zr 0.48 TiO 3 The process parameters of the film are: air pressure 2Pa, power 50W, substrate temperature 500°C, s...

Embodiment 3

[0055] The steps of this embodiment are as follows:

[0056] (1) On the Si substrate prepared with the first metal electrode Pt electrode, the first CaZrO with a thickness of 10 nm was sequentially prepared by radio frequency sputtering (JGP-560C10 ultra-high vacuum multifunctional magnetron sputtering equipment) 3 layer, LaNiO with a thickness of 30nm 3 Transition layer, BaTiO with a thickness of 800nm 3 Thin film, second CaZrO with a thickness of 10 nm 3 layer; preparation of the first CaZrO 3 The process parameters of the layer are: air pressure 2Pa, power 70W, substrate temperature 550°C, sputtering time 10min, Ar:O 2 =40:10 (volume ratio); prepare LaNiO 3 The process parameters of the transition layer are: air pressure 2Pa, power 50W, substrate temperature 550°C, sputtering time 10min, Ar:O 2 =40:10 (volume ratio); prepare BaTiO 3 The process parameters of the film are: air pressure 2Pa, power 50W, substrate temperature 500°C, sputtering time 300min, Ar:O 2 =40:10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com