Electromagnetic heating type oxygen generation method and oxygen generator

An oxygen generator and heating technology, applied in the direction of oxygen preparation, chemical instruments and methods, oxygen/ozone/oxide/hydroxide, etc., can solve the problem that the oxygen generator cannot be reused, the metal fuel is expensive, and the process cannot Control and other issues, to achieve the effect of prolonging storage time, reducing production time and cost, and reducing use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

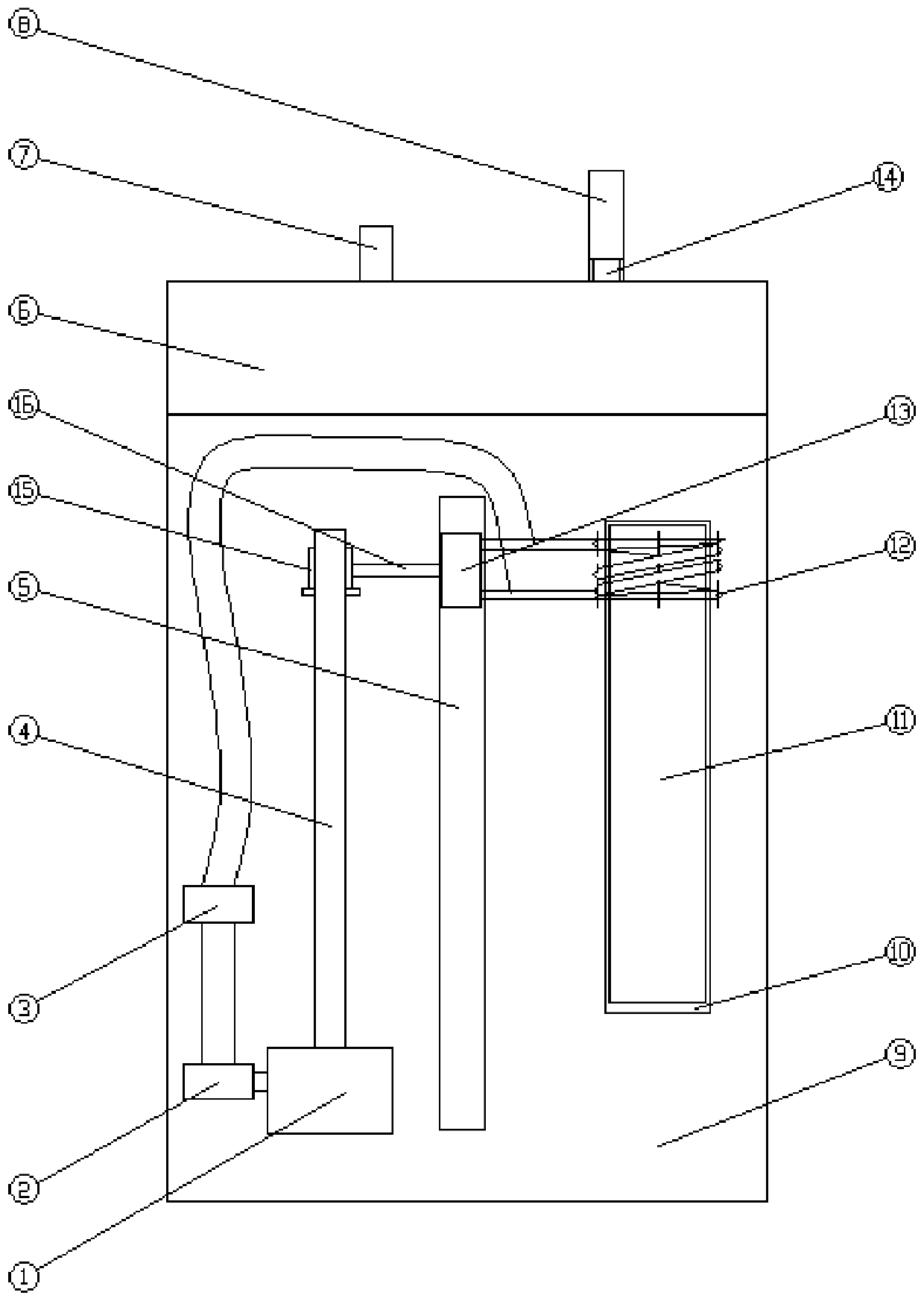

[0047] An electromagnetic heating type oxygen production method, the main method is as follows: take the following weight percentages: 75%-90% of chlorate or perchlorate, 0-8% of catalyst, 0-8% of chlorine inhibitor, 0% of adhesive -8%, 6-8% metal powder mixed and pressed into oxygen candle or tablet (hereinafter referred to as "oxygen candle"), put the oxygen candle into a container, heat it with an electromagnetic heater, and use transmission equipment to control Its heating position makes it decompose to release oxygen, which is discharged from the air outlet.

[0048] The catalyst is one or a mixture of nickel oxide, copper oxide, iron oxide, triiron tetroxide, tricobalt tetroxide, dicobalt trioxide and manganese dioxide.

[0049] The binder is silicon dioxide or mica powder or kaolin.

[0050] Described chlorine inhibitor is barium peroxide or sodium peroxide and other peroxides or superoxides.

[0051] The oxygen candle can be a single oxygen candle, or a tablet or a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com