Mult-stage printing and dyeing wastewater decolorizing treatment process

A technology for printing and dyeing wastewater and treatment process, which is applied in multi-stage water treatment, textile industry wastewater treatment, water/sewage multi-stage treatment, etc. The effect of filtration and treatment is not ideal, so as to achieve the effect of easy replacement, time saving, easy replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

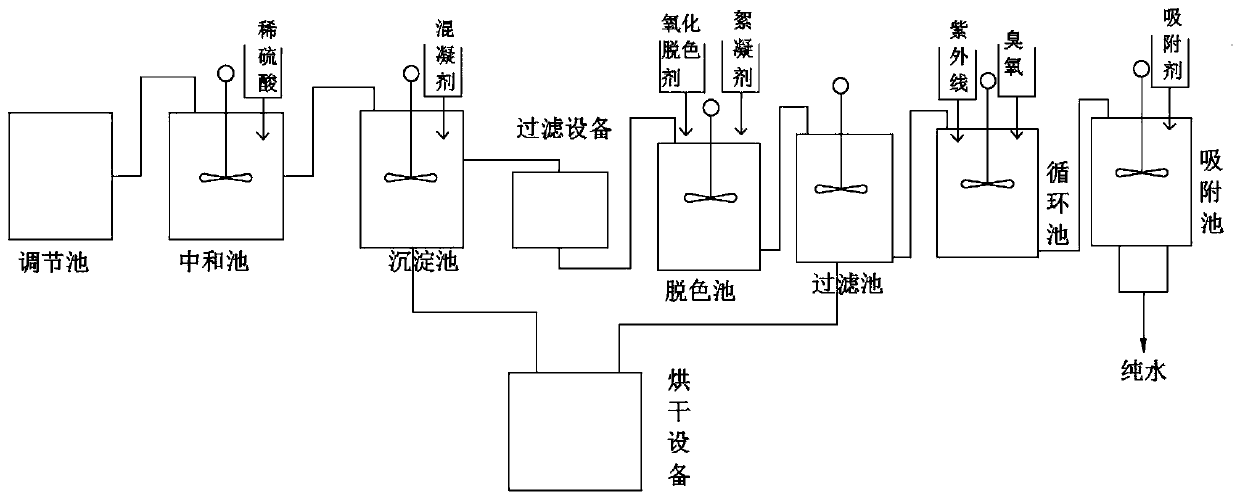

[0043] A multistage printing and dyeing wastewater decolorization treatment process, comprising the following steps:

[0044] S1: The pH value of the printing and dyeing wastewater before treatment is 10, the BOD is 1840, the SS suspended matter is 420, and the chroma is 1000. Discharge the printing and dyeing wastewater into the regulating tank to adjust the flow of the wastewater;

[0045] S2: Pass the wastewater in the adjustment tank into the neutralization tank, and neutralize the printing and dyeing wastewater with dilute sulfuric acid until the pH is 8.0;

[0046] S3: Pass the wastewater in the neutralization tank into the sedimentation tank, add coagulant to the sedimentation tank, the input volume ratio of coagulant to wastewater is 0.5:1000, stir the water tank at a speed of 80r / min for 30min, and let it settle 2h, and transport the sediment to the drying equipment;

[0047] S4: Pass the waste liquid in the upper layer of the sedimentation tank into the filter equip...

Embodiment 2

[0054] A multistage printing and dyeing wastewater decolorization treatment process, comprising the following steps:

[0055] S1: The pH value of the printing and dyeing wastewater before treatment is 10, the BOD is 1840, the SS suspended matter is 420, and the chroma is 1000. Discharge the printing and dyeing wastewater into the regulating tank to adjust the flow of the wastewater;

[0056] S2: Pass the wastewater in the adjustment tank into the neutralization tank, and neutralize the printing and dyeing wastewater with dilute sulfuric acid until the pH is 6.5;

[0057] S3: Pass the wastewater in the neutralization tank into the sedimentation tank, add coagulant to the sedimentation tank, the input volume ratio of coagulant to wastewater is 3:1000, stir the water tank at a speed of 30-80r / min for 10min, statically Place the sediment for 0.5h, and transport the sediment to the drying equipment;

[0058] S4: Pass the waste liquid in the upper layer of the sedimentation tank in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com