High-brightness 90 DEG C soft polyvinyl chloride sheath cable material and preparation method thereof

A soft polyvinyl chloride and polyvinyl chloride resin technology, which is applied in the field of high-brightness 90°C soft polyvinyl chloride sheathed cable material and its preparation field, can solve the problems affecting the appearance quality, feel and inferiority of the finished cable, and achieves black brightness and The effect of remarkable fineness, improved mechanical properties, and obvious mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

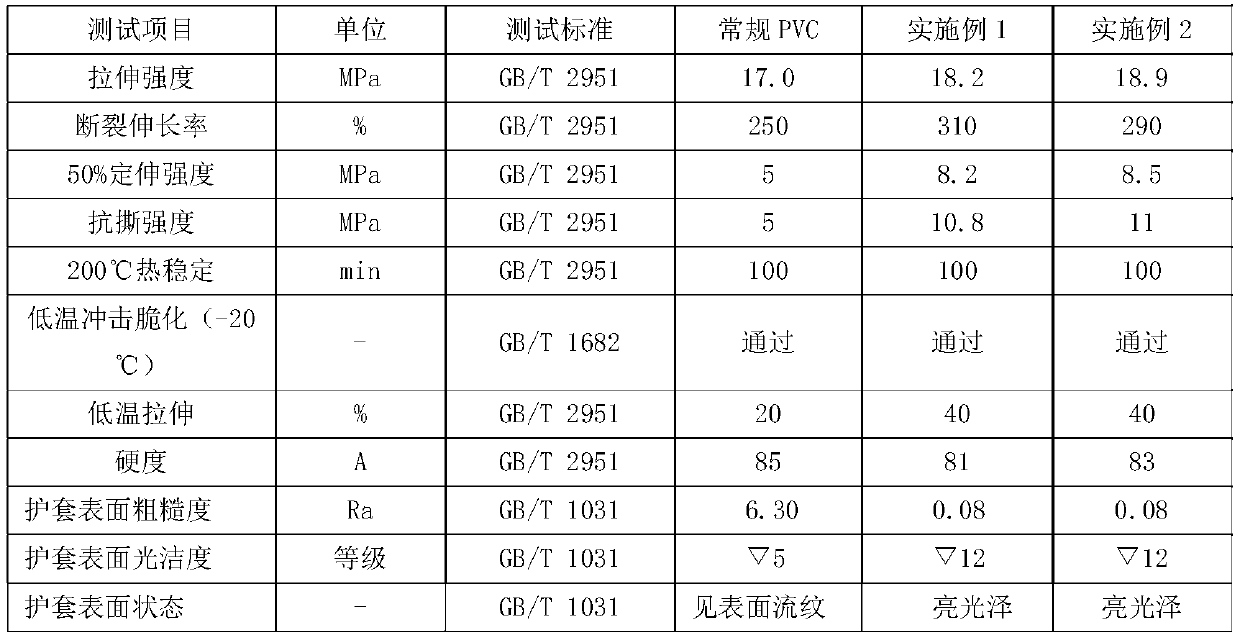

Examples

Embodiment Construction

[0040] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

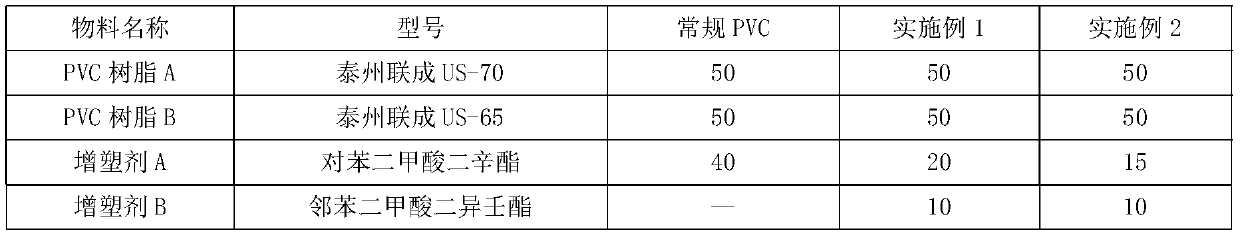

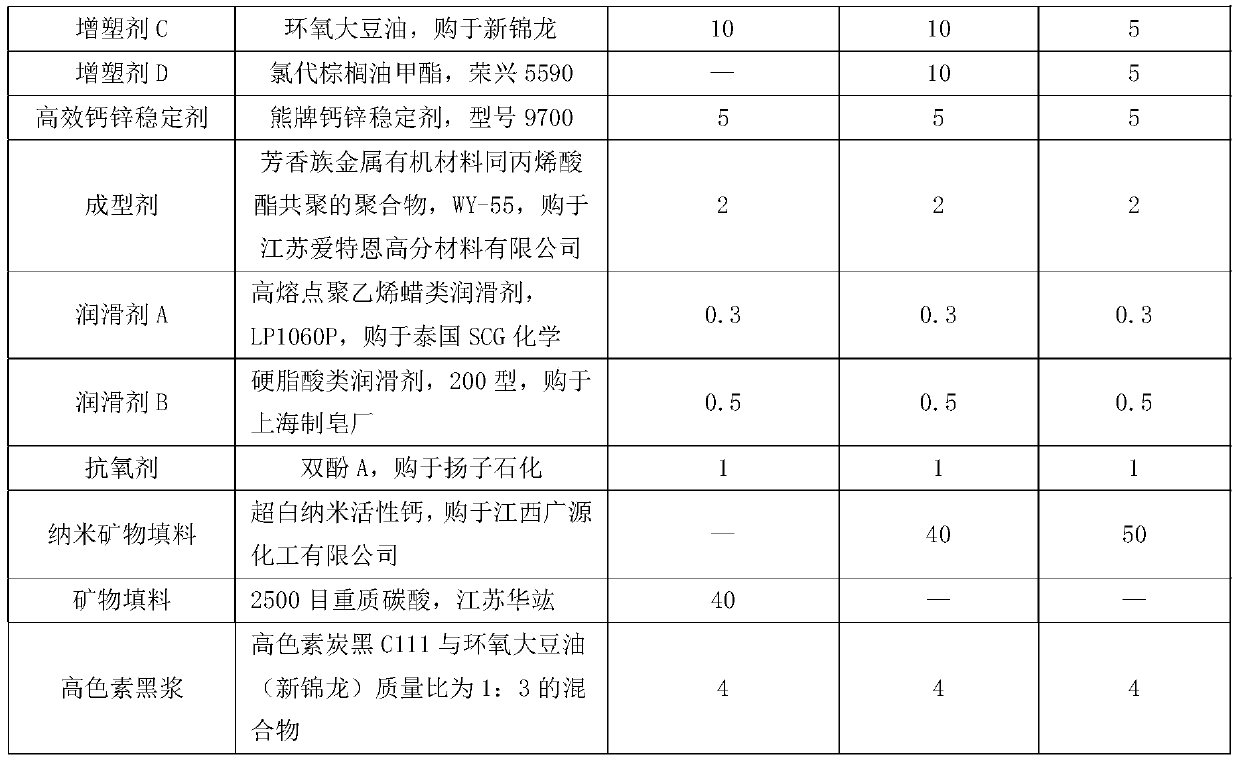

[0041] Table 1 The raw material composition table of each embodiment

[0042]

[0043]

[0044] Preparation method: the high-brightness 90°C soft polyvinyl chloride sheath material of the above-mentioned embodiment 1 and embodiment 2 were prepared according to the following method, including the following steps:

[0045] (a) PVC resin A, PVC resin B, forming agent, plasticizer B, plasticizer C, plasticizer D, lubricant A, lubricant B, antioxidant, high-efficiency calcium-zinc stabilizer , mineral fillers, and high-pigment black pulp are added to a high-speed mixer, and mixed for 6 minutes at 550 rpm and 90°C to 100°C. After the current of the high-speed mixer is stable, the materials are discharged into the cold mixing tank to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com