Anti-corrosion waterborne coating and preparation method and application thereof

A technology of water-based coatings and anti-corrosion coatings, applied in the field of coatings, can solve the problems of poor anti-corrosion performance and timeliness, and achieve the effect of improving timeliness, good anti-corrosion performance, and coating environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a kind of its preparation method of anticorrosion water-based coating, comprises the following steps:

[0031] S1. Synthesis of modified polyaniline;

[0032] Mix the aniline and the modifying agent containing the modifying group and then mix it with the oxidizing agent, and then let it stand for reaction. The specific operation is as follows:

[0033] Mixing aniline and a modifying agent containing a modifying group with a hydrochloric acid solution to form a first mixed solution;

[0034] Oxidant is mixed with hydrochloric acid solution to form the second mixed solution;

[0035] Then add the second mixed solution to the first mixed solution, stir and mix for 25-35S, and then stand for 20-30h;

[0036] Then wash the solid matter formed by the reaction, and freeze-dry to form the modified polyaniline.

[0037] The above operation method can ensure that the prepared modified polyaniline has excellent water solubility, and then ensu...

Embodiment 1

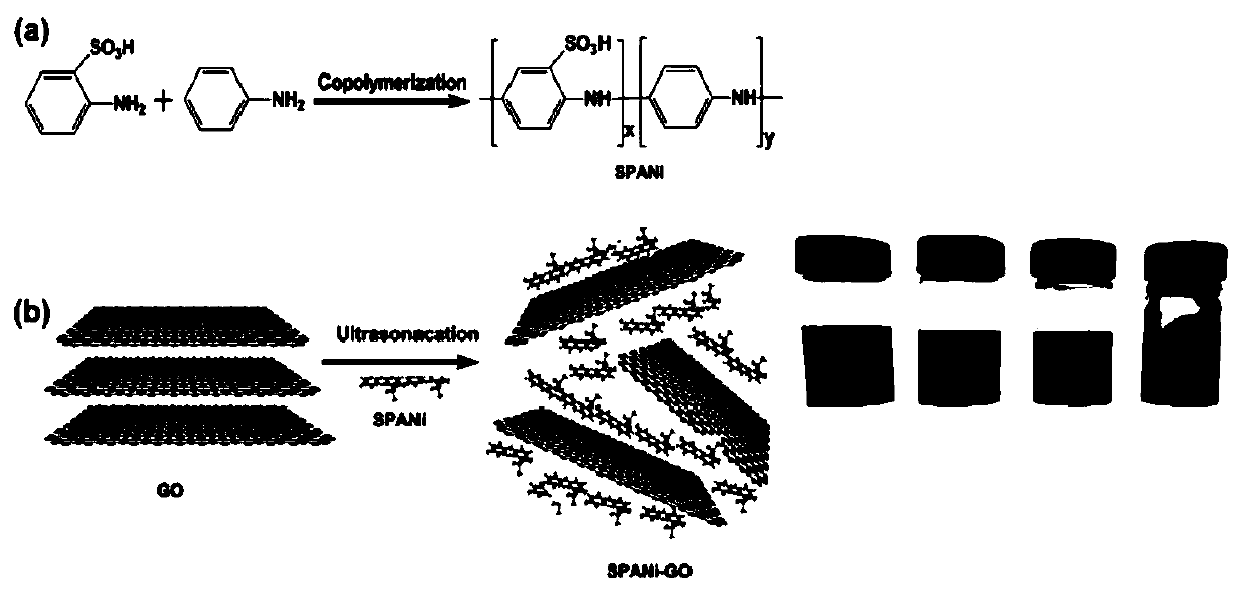

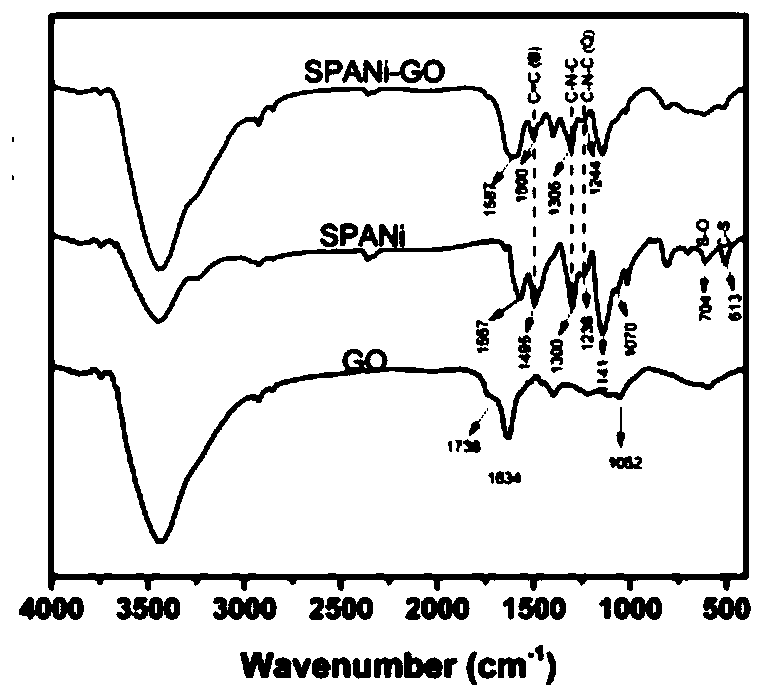

[0069] The present embodiment provides a kind of anticorrosion water-based paint (numbering is SPGO-0.3%), and its raw material comprises modified polyaniline-graphene oxide composite material and water-based epoxy resin, and the quality of modified polyaniline-graphene composite material accounts for water-based 0.9% of epoxy resin mass. Among them, the modified polyaniline-graphene oxide composite material is a sulfonated polyaniline-graphene oxide composite material, and the number of layers of graphene oxide in the modified polyaniline-graphene oxide composite material is less than 5 layers, mostly 2- 3 floors.

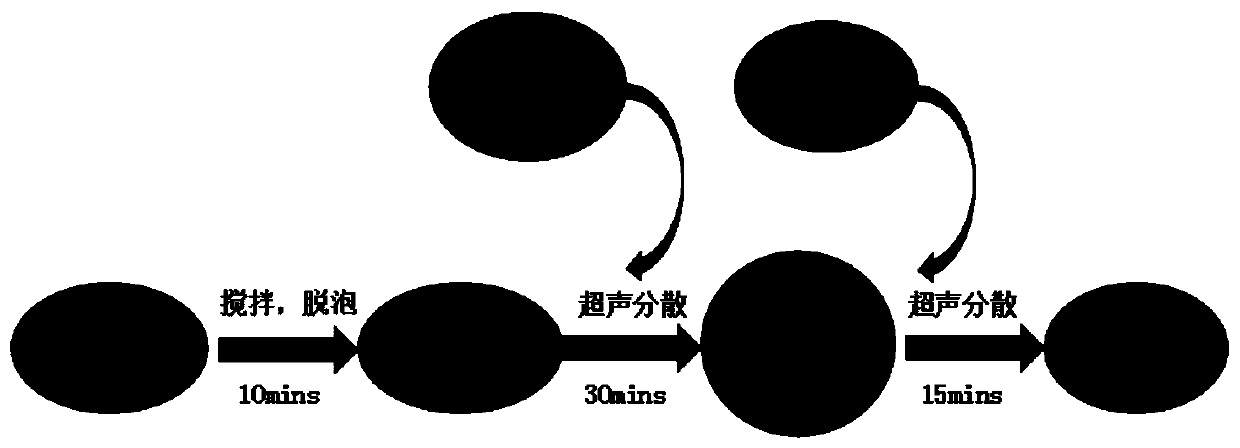

[0070] see figure 1 and figure 2 , present embodiment also provides a kind of its preparation method of anticorrosion water-based paint, comprises the following steps:

[0071] S1, synthesis of sulfonated polyaniline;

[0072] Dissolve 0.93g of aniline Ani (10mmol) and 1.73g of 2-aminobenzenesulfonic acid ASA (10mmol) in an Erlenmeyer flask containing 100ml o...

Embodiment 2- Embodiment 4

[0085] Embodiment 2-embodiment 4 provides a kind of anticorrosion water-based coating and the raw material and the preparation method of the anticorrosion water-based coating that embodiment 1 provides are all the same, the difference is that the quality of modified polyaniline-graphene composite material accounts for the different quality of water-based epoxy resin ,Specifically:

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com