Treating agent for retarding fading of pure cotton fabrics and utilization method of treating agent

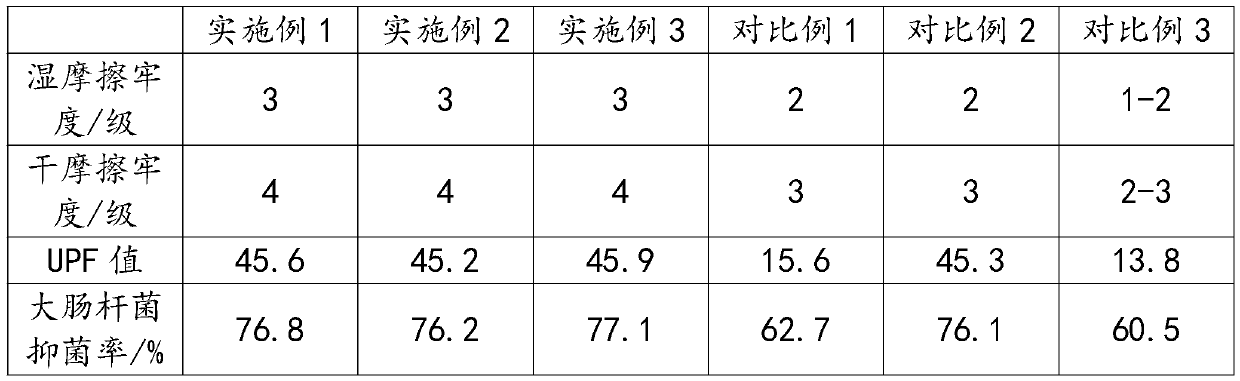

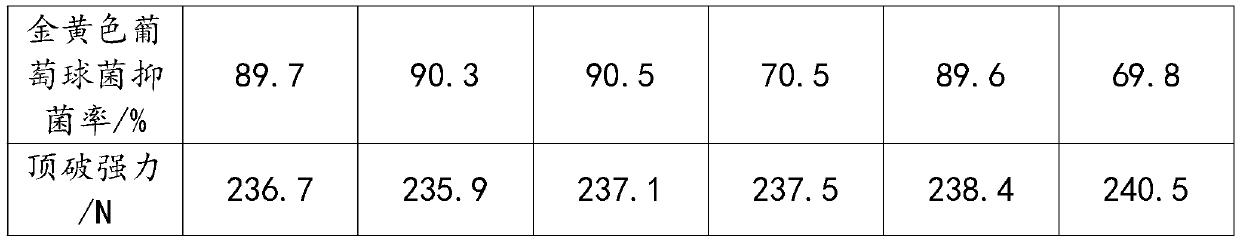

A pure cotton fabric and treatment agent technology, which is applied in fiber treatment, biochemical fiber treatment, plant fiber, etc., can solve the problems of complex composition of treatment agent, multiple side reactions, and affecting the treatment effect of pure cotton fabric, so as to improve the anti-ultraviolet performance , slow down color fading, improve the effect of color fastness to rubbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Treat pure cotton fabrics as follows:

[0050] Step 1: Soak the desized pure cotton fabric in warm water at 30°C for 2 hours;

[0051] The second step is to raise the temperature of the wet rubbing fastness improving emulsion to 70°C, immerse the pure cotton fabric soaked in warm water into the wet rubbing fastness improving emulsion, and perform one dipping and one rolling at a constant temperature of 70°C, and the liquid retention rate is 80% %, and dried in an oven at 85°C;

[0052] The third step, the antibacterial finishing agent is heated up to 40°C, the cotton fabric treated in step S2 is immersed in the antibacterial finishing agent, two dipping and two rolling, the excess rate is 70%, pre-baked in an oven at 80°C for 5min, and then Bake at 120°C for 3 minutes;

[0053] In the fourth step, the baked pure cotton fabric was repeatedly washed 6 times with tap water at room temperature, and dried at 60° C. to a constant weight.

Embodiment 2

[0055] Treat pure cotton fabrics as follows:

[0056] Step 1: Soak the desized pure cotton fabric in warm water at 30°C for 2 hours;

[0057] The second step is to raise the temperature of the wet rubbing fastness improving emulsion to 73°C, immerse the pure cotton fabric soaked in warm water into the wet rubbing fastness improving emulsion, and perform one dipping and one rolling at a constant temperature of 73°C, and the liquid retention rate is 85%. %, and dried in an oven at 85°C;

[0058] Step 3: Warm up the antibacterial finishing agent to 43°C, immerse the cotton fabric treated in step S2 in the antibacterial finishing agent, perform two dipping and two padding, with a pass rate of 75%, pre-bake in an oven at 80°C for 5 minutes, and then Bake at 120°C for 3 minutes;

[0059] In the fourth step, the baked pure cotton fabric was repeatedly washed 7 times with tap water at room temperature, and dried to a constant weight at 60°C.

Embodiment 3

[0061] Treat pure cotton fabrics as follows:

[0062] Step 1: Soak the desized pure cotton fabric in warm water at 30°C for 2 hours;

[0063] The second step is to raise the temperature of the wet rubbing fastness improving emulsion to 75°C, immerse the pure cotton fabric soaked in warm water into the wet rubbing fastness improving emulsion, and perform one dipping and one rolling at a constant temperature of 75°C, and the liquid retention rate is 90% %, and dried in an oven at 85°C;

[0064] The third step, the antibacterial finishing agent is heated up to 45°C, the cotton fabric treated in step S2 is immersed in the antibacterial finishing agent, two dipping and two rolling, the excess rate is 80%, pre-baked in an oven at 80°C for 5min, and then Bake at 120°C for 3 minutes;

[0065] In the fourth step, the baked pure cotton fabric is repeatedly washed 8 times with tap water at room temperature, and dried at 60° C. to a constant weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com