Preparation method of fireproof non-toxic automotive interior organic silicon leather

A technology of automotive interior and silicone, which is applied in the field of preparation of fire-resistant and non-toxic silicone leather for automotive interior, to achieve long service life, good environmental performance, and meet performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

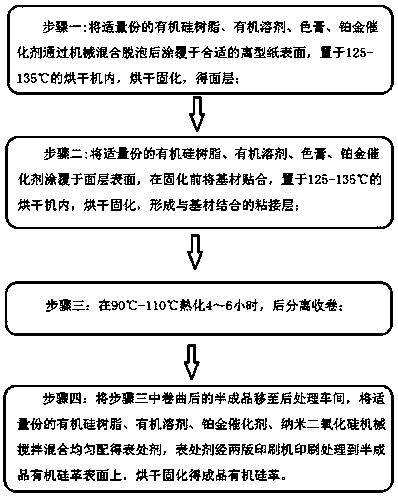

[0022] see figure 1 , the present embodiment provides a kind of non-toxic, fireproof, the preparation method of the organic silicon leather of low VOC automobile interior decoration, and it comprises the following steps:

[0023] Step 1: Apply 80 parts of silicone resin, 20 parts of organic solvent, 7 parts of color paste, and 0.3 parts of platinum catalyst to the surface of a suitable release paper after mechanical mixing and degassing, place in a dryer at 130 ° C, and dry Dry and solidify to obtain the surface layer;

[0024] Step 2: Coat 80 parts of silicone resin, 10 parts of organic solvent, 5 parts of color paste, and 0.3 parts of platinum catalyst on the surface of the surface layer, attach the substrates before curing, and place them in a dryer at 130 ° C. Drying and curing to form an adhesive layer combined with the substrate;

[0025] Step 3: aging at 90°C for 6 hours, then separating and winding;

[0026] Step 4: Move the semi-finished product crimped in Step 3 t...

Embodiment 2

[0028] see figure 1 , the present embodiment provides a kind of non-toxic, fireproof, the preparation method of the organic silicon leather of low VOC automobile interior decoration, and it comprises the following steps:

[0029] Step 1: Apply 80 parts of silicone resin, 30 parts of organic solvent, 7 parts of color paste, and 0.5 parts of platinum catalyst to the surface of a suitable release paper after mechanical mixing and degassing, place in a dryer at 135 ° C, and dry Dry and solidify to obtain the surface layer;

[0030] Step 2: Coat 80 parts of silicone resin, 15 parts of organic solvent, 5 parts of color paste, and 0.3 part of platinum catalyst on the surface of the surface layer, attach the substrates before curing, and place them in a dryer at 135 ° C. Drying and curing to form an adhesive layer combined with the substrate;

[0031] Step 3: aging at 100°C for 5 hours, then separating and winding;

[0032] Step 4: Move the semi-finished product curled in Step 3 to...

Embodiment 3

[0034] see figure 1 , the present embodiment provides a kind of non-toxic, fireproof, the preparation method of the organic silicon leather of low VOC automobile interior decoration, and it comprises the following steps:

[0035] Step 1: 50 parts of silicone resin, 15 parts of organic solvent, 6 parts of color paste, and 0.3 parts of platinum catalyst are degassed by mechanical mixing and then coated on the surface of a suitable release paper, placed in a dryer at 135 ° C, and dried Dry and solidify to obtain the surface layer;

[0036] Step 2: Coat 50 parts of silicone resin, 11 parts of organic solvent, 5 parts of color paste, and 0.2 parts of platinum catalyst on the surface of the surface layer. Before curing, the substrates are bonded together and placed in a dryer at 135 ° C. Drying and curing to form an adhesive layer combined with the substrate;

[0037] Step 3: aging at 95°C for 4.5 hours, then separating and winding;

[0038] Step 4: Move the semi-finished product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com