A kind of high-strength fabric film compound and preparation method thereof

A high-strength, composite technology, applied in the direction of fabric surface trimming, chemical instruments and methods, heating/cooling fabrics, etc., can solve the problems of composite hardness, tensile strength and elongation decrease, cost increase, unfavorable production, etc. Achieve the effect of excellent peeling fastness, reduce production cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

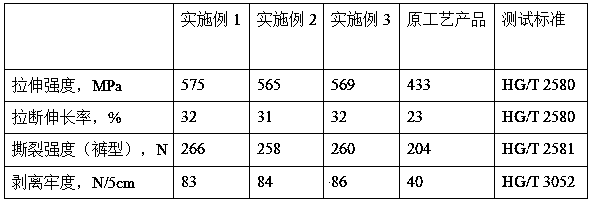

Embodiment 1

[0027] The high-strength fabric-film composite is prepared according to the following formula ratio, requirements of each component and process method.

[0028] Nylon fabrics in which ultra-high molecular weight polyethylene fibers account for 3% of the nylon fiber mass;

[0029] Low-melting point TPU film layer: low-melting point TPU mask layer and low-melting point TPU bottom film layer are polyester thermoplastic polyurethane elastomers, and the molecular weight of the soft polybutyl adipate used in its synthesis is 500~700, and the hydroxyl value is 105~110 mg KOH / g, the proportion of soft segment is 50~60wt%, the Shore hardness is 60A~75A, the weight average molecular weight is 80,000~90,000, the molecular weight distribution is 2.0~2.5, and the melting range is 120~130℃.

[0030] PU adhesive, comprising the following components by weight:

[0031] Polyurethane PU glue: 100 parts

[0032] Closed water-based curing agent: 10 parts

[0033] Butanone solvent: 10 parts

...

Embodiment 2

[0043] The high-strength fabric-film composite is prepared according to the following formula ratio, requirements of each component and process method.

[0044] Nylon fabrics in which UHMWPE fibers account for 4% of the nylon fiber mass

[0045]Low-melting point TPU film layer: low-melting point TPU mask layer and low-melting point TPU bottom film layer are polyester thermoplastic polyurethane elastomers, and the molecular weight of the soft polybutyl adipate used in its synthesis is 500~700, and the hydroxyl value is 105~110 mg KOH / g, the proportion of soft segment is 50~60wt%, the Shore hardness is 60A~75A, the weight average molecular weight is 80,000~90,000, the molecular weight distribution is 2.0~2.5, and the melting range is 120~130℃.

[0046] PU adhesive, comprising the following components by weight:

[0047] Polyurethane PU glue: 100 parts

[0048] Closed water-based curing agent: 10 parts

[0049] Butanone solvent: 10 parts

[0050] The blocked water-based curin...

Embodiment 3

[0059] The high-strength fabric-film composite is prepared according to the following formula ratio, requirements of each component and process method.

[0060] Nylon fabrics in which ultra-high molecular weight polyethylene fibers account for 5% of the nylon fiber mass

[0061] Low-melting point TPU film layer: low-melting point TPU mask layer and low-melting point TPU bottom film layer are polyester thermoplastic polyurethane elastomers, and the molecular weight of the soft polybutyl adipate used in its synthesis is 500~700, and the hydroxyl value is 105~110 mg KOH / g, the proportion of soft segment is 50~60wt%, the Shore hardness is 60A~75A, the weight average molecular weight is 80,000~90,000, the molecular weight distribution is 2.0~2.5, and the melting range is 120~130℃.

[0062] PU adhesive, comprising the following components by weight:

[0063] Polyurethane PU glue: 100 parts

[0064] Closed water-based curing agent: 10 parts

[0065] Butanone solvent: 10 parts

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com