Anode catalyst for direct borohydride fuel cell, anode material, preparation method of anode material, and fuel cell

A fuel cell and borohydride technology, applied in fuel cells, nanotechnology for materials and surface science, molten electrolyte fuel cells, etc., can solve the problems of catalyst catalytic efficiency and low fuel utilization efficiency, and achieve suitable large-scale Preparation, easily repeatable, performance-improving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] According to another aspect of the present invention, there is also provided a method for preparing an anode catalyst for direct borohydride fuel cells as described above, comprising the following steps: mixing boric acid, ammonium salt, potassium sodium tartrate, tricobalt tetroxide and stannous sulfate , add water and stir to obtain A solution; mix an alkali solution with a pH value of 12 to 13 and sodium borohydride to obtain a B solution; mix A and B solutions, and place them in a water bath until the reaction ends when no bubbles are generated. The solid powder was obtained by filtration, and the solid powder was washed and dried to obtain an anode catalyst for direct borohydride fuel cells. The preparation method of the direct borohydride fuel cell anode catalyst of the present invention adopts a simple chemical reduction method to obtain the direct borohydride fuel cell anode catalyst, the process is simple, low in cost, easy to repeat, suitable for large-scale pr...

Embodiment 1

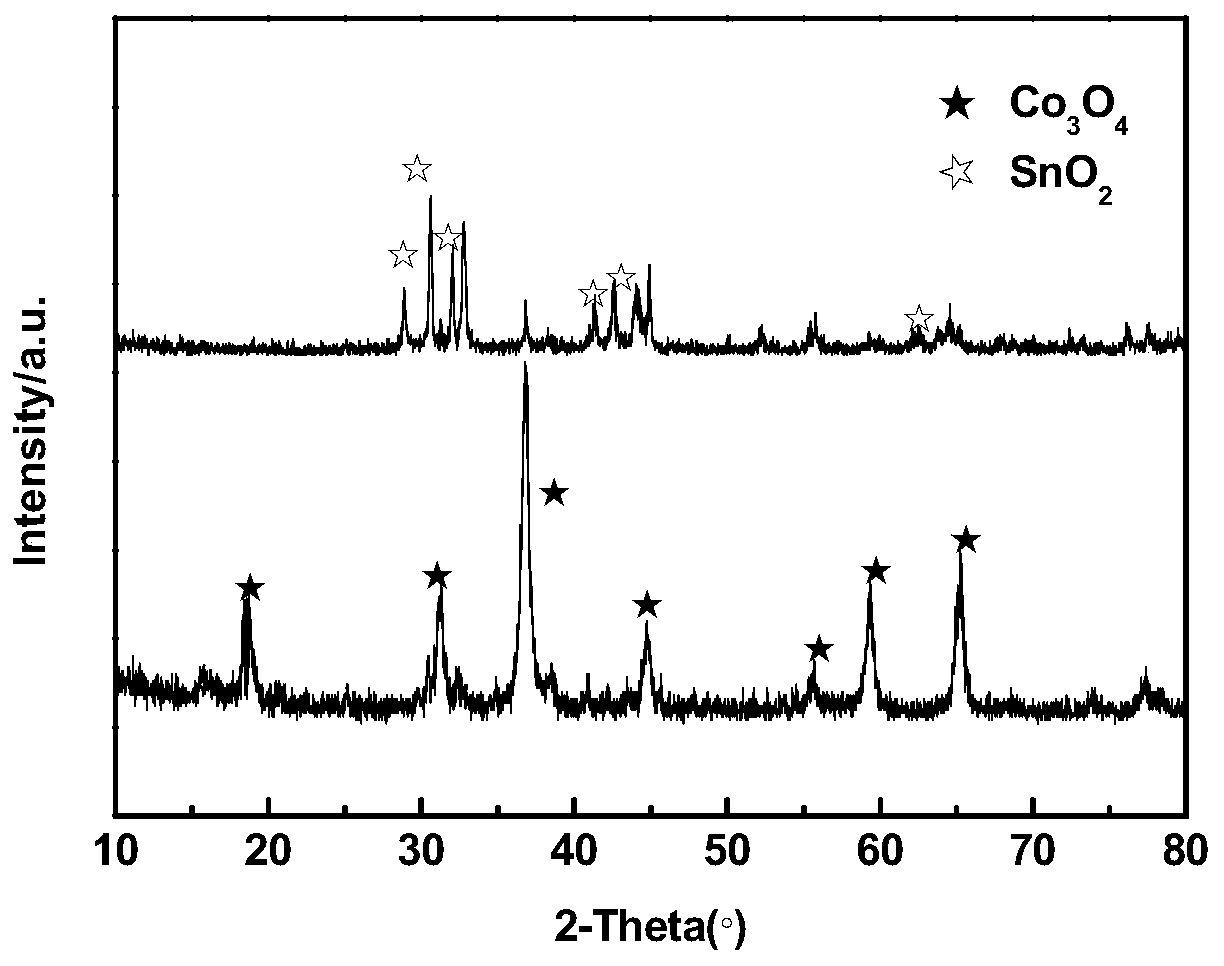

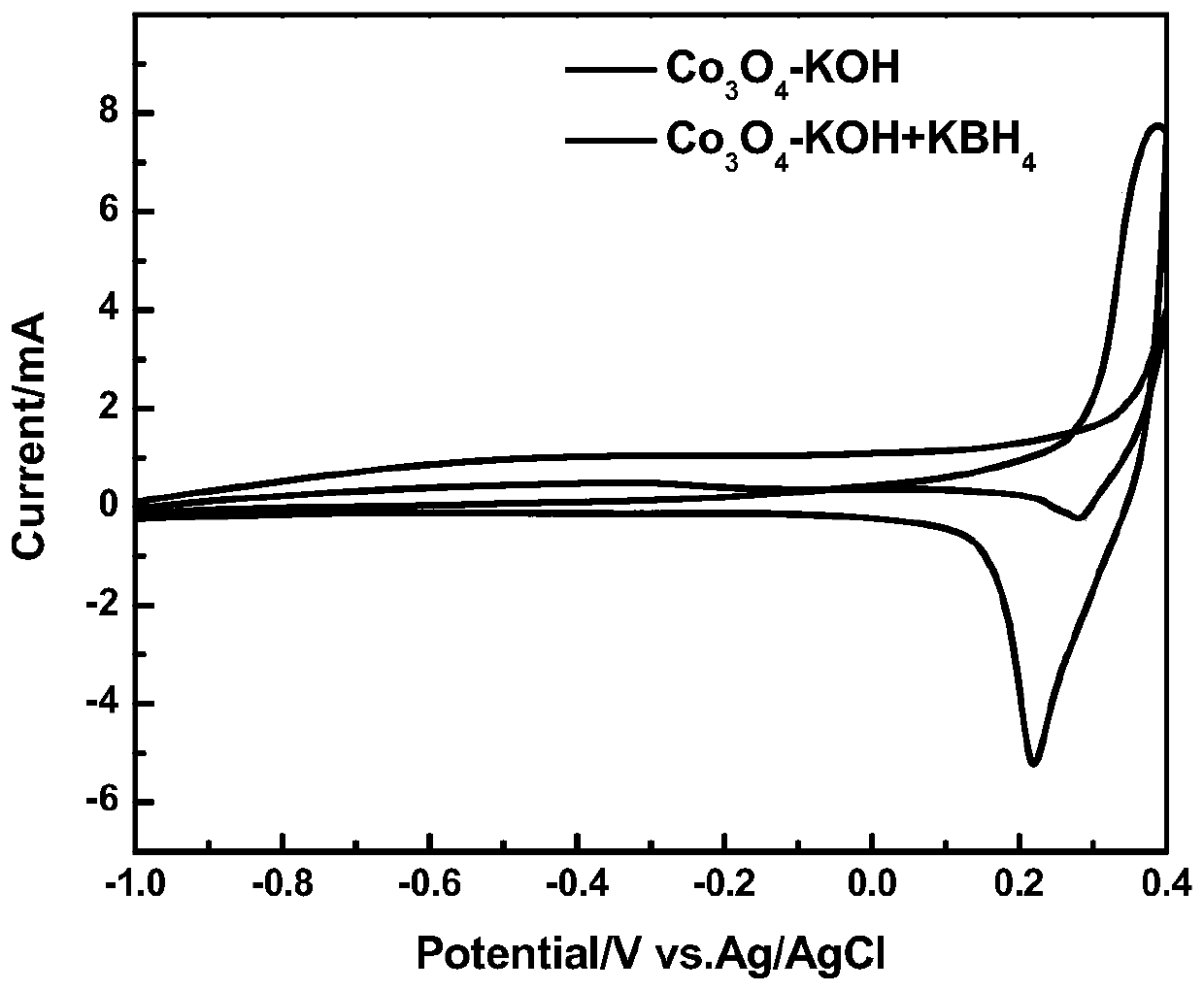

[0049] The anode catalyst for the direct borohydride fuel cell of the present embodiment: Co 3 o 4 / SnO 2 , spherical Co 3 o 4 Attached to lamellar SnO 2 On the surface, lamellar SnO 2 Intertwined to form a 3D structure; Co 3 o 4 The particle size is between 30nm and 40nm, SnO 2 The sheet thickness is 10nm.

[0050] The preparation method of the anode catalyst for the above-mentioned direct borohydride fuel cell is:

[0051] Weigh 40mg of borax, 400mg of ammonium chloride, 1.22mg of potassium sodium tartrate, 2.1mg of tricobalt tetroxide, 1.6mg of stannous sulfate and mix them evenly into a beaker, then measure 20mL of distilled water and add to stir to form A solution;

[0052] Weigh 1.66mg of sodium hydroxide, add 40mL of distilled water and stir, adjust the pH value to 12-13 with dilute hydrochloric acid, measure 20mL of sodium hydroxide solution, add 1.79mg of sodium borohydride and stir to form B solution;

[0053] Mix and stir solution A and solution B, put the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com