Food waste and kitchen garbage pretreatment method

A technology of kitchen waste and kitchen waste, applied in the field of waste treatment, can solve the problems of affecting resource utilization, complex components, high maintenance cost, etc., and achieve the effect of saving one-time input cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

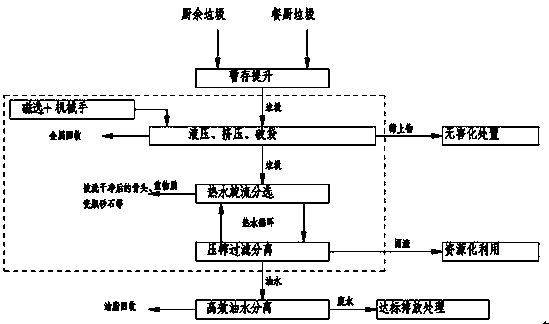

[0024] Such as figure 1 As shown, the present invention provides a pretreatment method for food waste, which can temporarily store and lift food waste and food waste at the same time; perform hydraulic pressure, extrusion, and bag breaking in sequence along the logistics direction, and can crush mineral water bottles , beverage bottles, various easy-to-pull irrigation, etc., and crush porcelain, glass bottles, and vegetable dregs in organic waste, etc., and effectively separate the sieve from the sieve through the sieve holes. After this step of treatment, Metals, plastics, lunch boxes, wooden chopsticks and other sieves can be effectively separated, while the undersieves enter the hot water cyclone sorting system; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com