Welding waveform control method for gas metal arc welding of nickel-based alloy

A technology of melting electrode gas and nickel-based alloys, applied in welding equipment, welding accessories, manufacturing tools, etc., can solve the problems of difficult droplet transfer, poor welding effect, incomplete droplet transfer, etc., to achieve all-position welding, The effect of high deposition efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

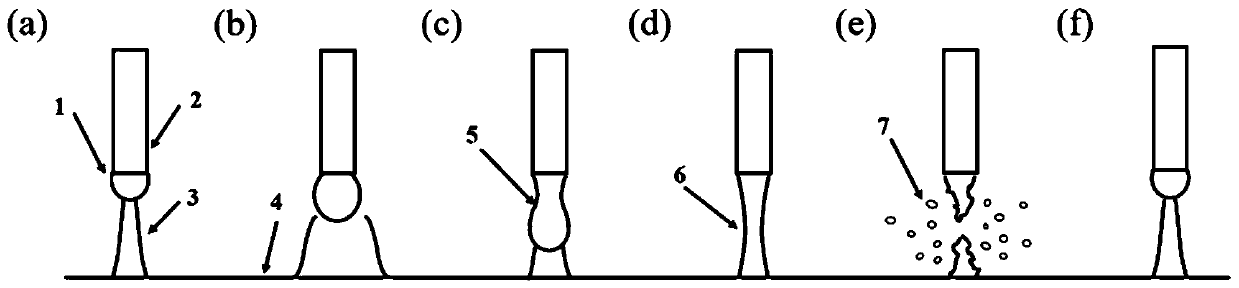

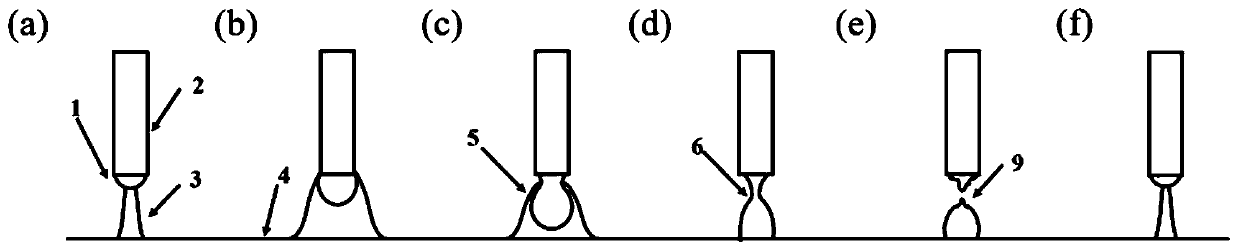

[0048] In the S-P-GMAW welding method, welding current control is the core technology to suppress spatter. like Figure 4 As shown, the present invention provides a preferred embodiment of a welding waveform control method for gas metal arc welding of nickel-based alloys. The specific control period corresponds to the welding process.

[0049] Figure 4 Stage A is the base value stage (corresponding to image 3 -a): Set the welding voltage to 20V, the welding current to 35A, and the duration t 1 Set it to 8ms to maintain stable combustion of arc 3;

[0050] Figure 4 Middle B stage is the early stage of pulse stage (corresponding to image 3 -b): Set welding voltage to 43V, welding current to 480A, duration t 2 Set it to 0.9ms, so that the welding wire 2 melts rapidly, and the droplet 1 grows rapidly;

[0051] Figure 4 Middle C stage is the late stage of pulse stage (corresponding to image 3 -c): Set welding voltage to 44V, welding current to 520A, duration t 3 Se...

Embodiment 2

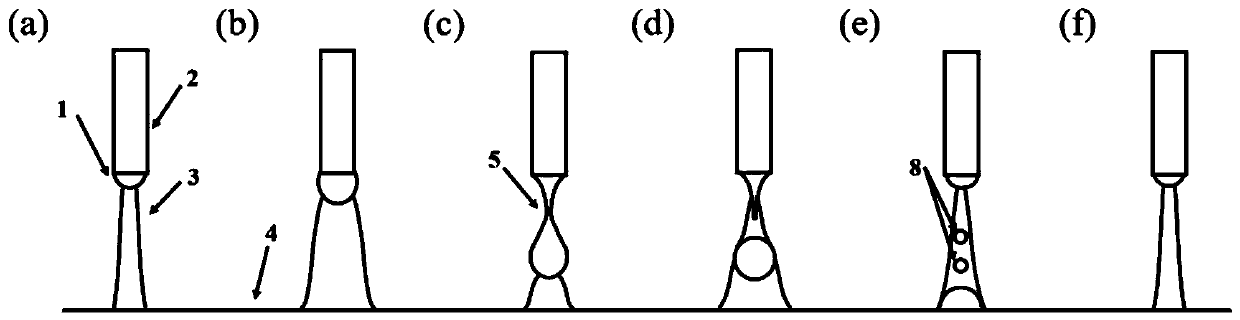

[0057] like Figure 5 As shown, another preferred embodiment of the method for controlling the welding waveform of a nickel-based alloy gas shielded metal arc welding provided by the present invention. The specific control period corresponds to the welding process.

[0058] Figure 5 Stage A is the base value stage (corresponding to image 3 -a): Set welding voltage to 21V, welding current to 40A, duration t 1 Set it to 7.5ms to maintain stable combustion of arc 3;

[0059] Figure 5 Middle B stage is the early stage of pulse stage (corresponding to image 3 -b): Set welding voltage to 41V, welding current to 460A, duration t 2 Set it to 1.0ms, so that the welding wire 2 melts rapidly, and the droplet 1 grows rapidly;

[0060] Figure 5 Middle C stage is the late stage of pulse stage (corresponding to image 3 -c): Set welding voltage to 46V, welding current to 540A, duration t 3 Set to 1.3ms, so that the droplet is elongated and necked;

[0061] Figure 5 The midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com