A kind of slag cleaning device for numerical control machine tool

A CNC machine tool and slag cleaning technology, which is used in metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc. It can solve the problems that iron filings cannot be cleaned, the tool has no cooling structure, and it is not easy to clean, and the waiting time is reached. less, reduce work intensity, increase the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

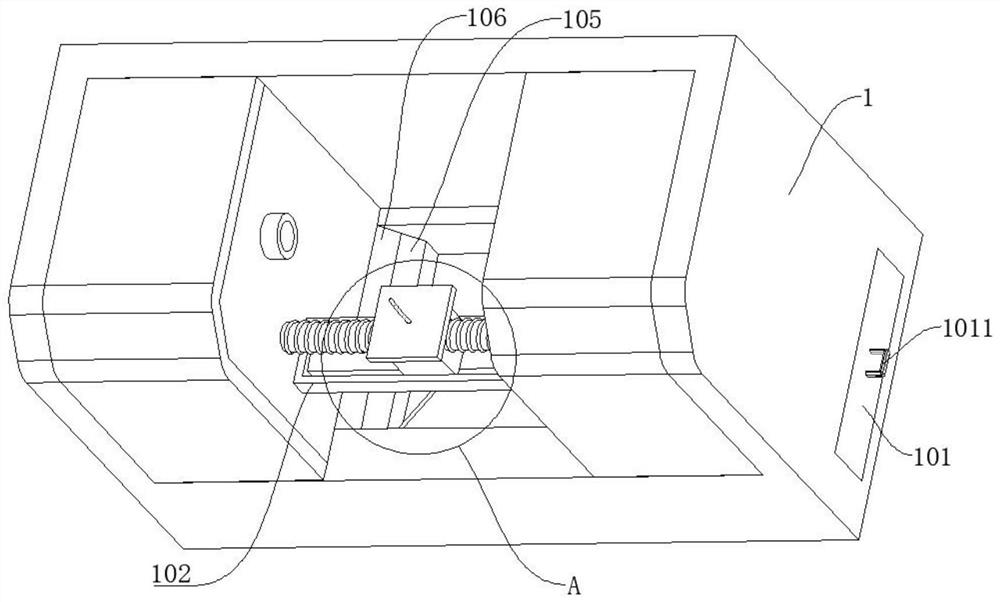

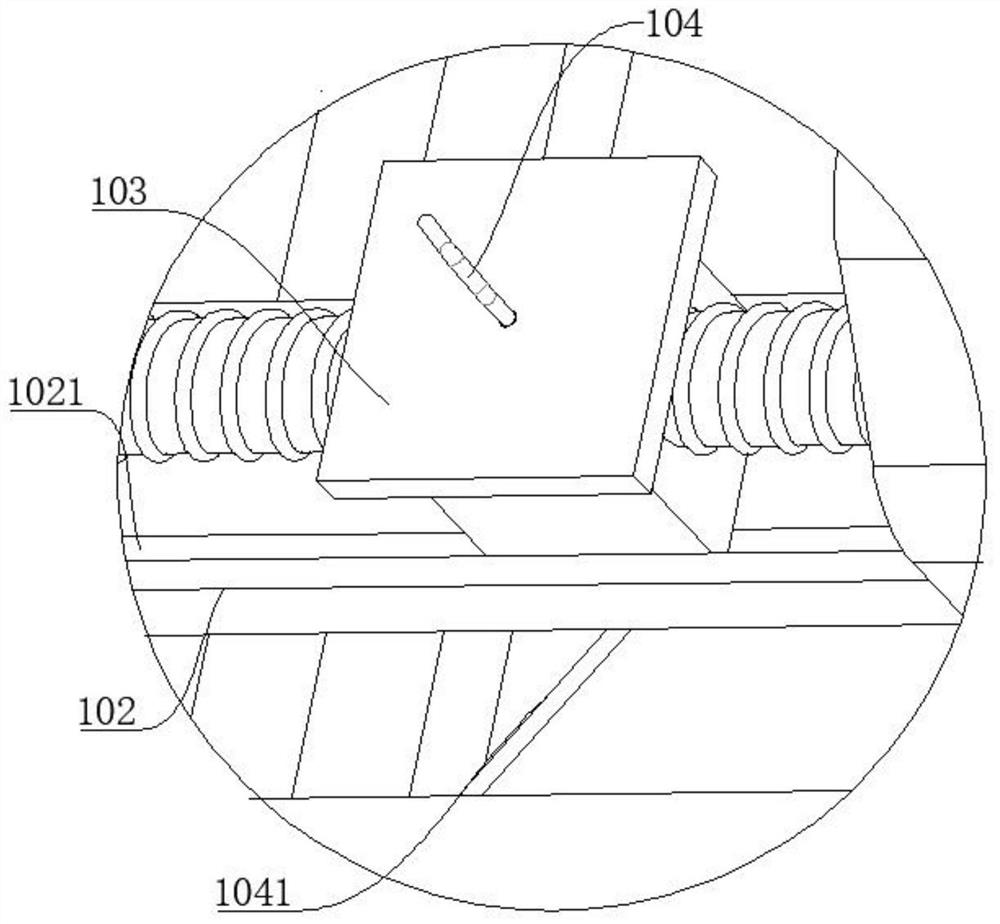

[0035] refer to Figure 1-10, a slag removal device for a numerically controlled machine tool, comprising a machine tool part 1, a sliding support bar 102 is fixedly connected to the machine tool, a tool holder 103 is fixedly connected to the sliding support bar 102, and a stepping motor 2, a collection box 101 is also included. The box 101 is movably connected to the machine tool 1, and the end of the machine tool 1 away from the collection box 101 is slidably connected to a first push plate 106, the stepping motor 2 is fixedly connected to the machine tool 1, and the output end of the stepping motor 2 is fixedly connected to a Screw mandrel 201, the first connecting block 202, the second connecting block 2021 are threadedly connected on the screw mandrel 201, the screw thread direction on the first connecting block 202 and the second connecting block 2021 is opposite, and the first connecting block 202 is connected with the first connecting block 202 in rotation. A telescopi...

Embodiment 2

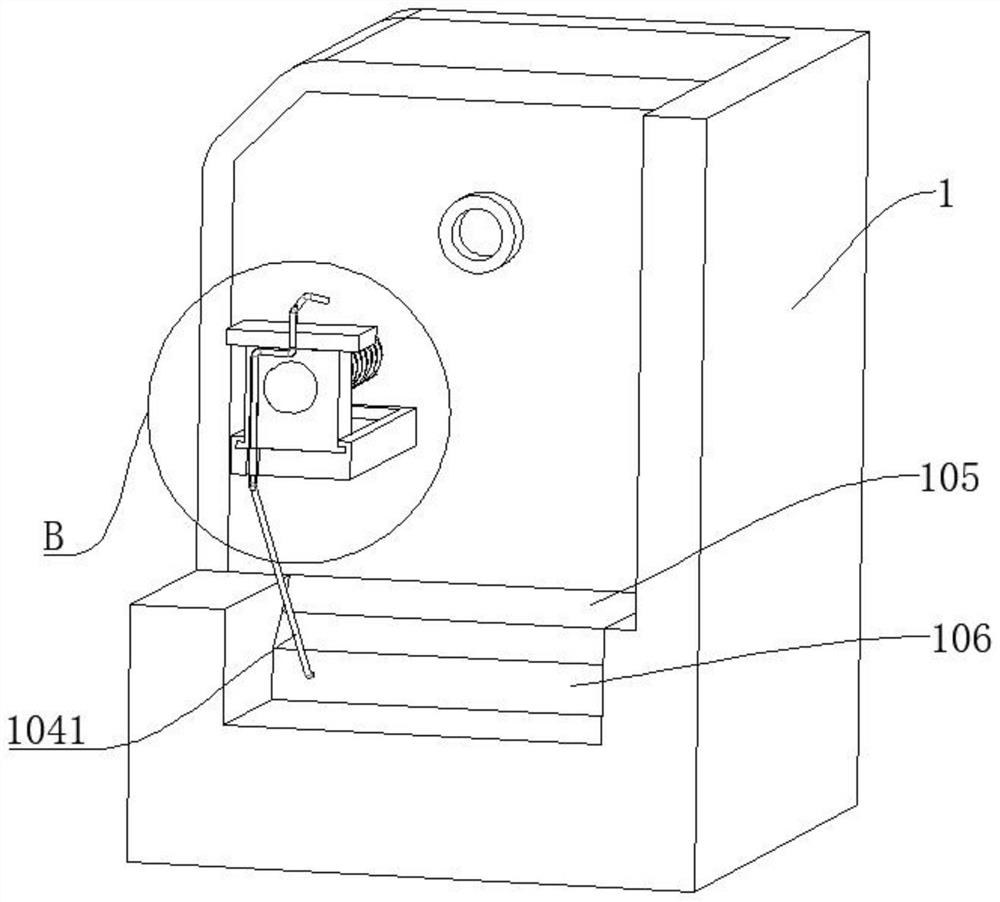

[0045] refer to Figure 1-10 , is basically the same as Embodiment 1, furthermore, it also includes a second push plate 105, the second push plate 105 is slidably connected to the machine tool 1, and the first push plate 106 is slidably connected to the first push plate 105 below the second push plate 105. The side of the push plate 106 close to the second push plate 105 is fixedly connected with a block;

[0046] The end of the second push plate 105 close to the collection box 101 is inclined;

[0047] By the second push plate 105, the waste chips can be pushed farther, and the slope on the second push plate 105 can make the waste chips roll down to the front of the first push plate 106 when the second push plate 105 is not moving. , so that the effect of cleaning debris is better.

Embodiment 3

[0049] refer to Figure 1-10 , is basically the same as Embodiment 1, the difference is that the first piston cylinder 3 includes a first piston cylinder 301, a third piston cylinder 303, the third piston cylinder 303 is slidably connected in the first piston cylinder 301, and the first piston cylinder One end of the barrel 301 away from the third piston barrel 303 is fixedly connected to the machine tool 1, and the end of the third piston barrel 303 away from the first piston barrel 301 is fixedly connected to the first push plate 106. Gas port 3001 matches.

[0050] When the first push plate 106 pushes the waste, the first push plate 106 will pull the third piston barrel 303 to slide in the first piston barrel 301, and then the space in the first piston barrel part 3 will increase, and the outside air will pass through the machine tool parts. 1. The first air inlet 3001 enters into the first piston cylinder 3, and the gas at the working place of the cutter can enter the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com