Microwave dielectric ceramic and preparation method thereof

A microwave dielectric ceramic and ceramic technology, applied in the field of microwave dielectric ceramics, can solve the problems of large equipment loss and high energy consumption, and achieve the effects of low cost, low sintering temperature and suitable for large-scale industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a method for preparing microwave dielectric ceramics described in the above technical solution, comprising the following steps:

[0044] a) CaCO 3 、Sm 2 o 3 、TiO 2 and Al 2 o 3 After mixing, the first grinding treatment is carried out, and then pre-sintering is carried out to obtain pre-sintered material; then the obtained pre-sintered material is subjected to second grinding treatment to obtain powder;

[0045] b) adding a binder to the powder obtained in step a) for granulation and molding to obtain a ceramic green body; and then sintering the obtained ceramic green body to obtain a microwave dielectric ceramic.

[0046] In the present invention, CaCO 3 、Sm 2 o 3 、TiO 2 and Al 2 o 3 After mixing, the first grinding treatment is carried out, and then pre-sintering is carried out to obtain pre-sintered material; then the obtained pre-sintered material is subjected to second grinding treatment to obtain powder. The present ...

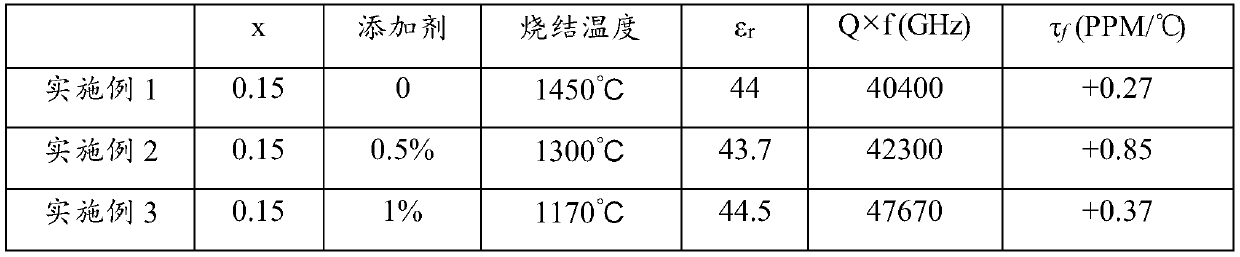

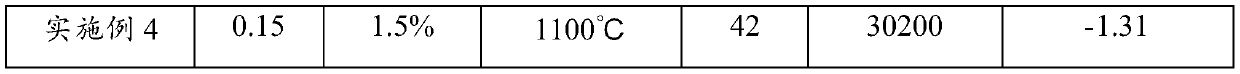

Embodiment 1

[0076] (1) Weigh 29.95g CaCO according to x=0.15 3 , 108.95g Sm 2 o 3 , 59.75g TiO 2 and 1.35g Al 2 o 3 The above raw materials, zirconium balls, and deionized water are wet-milled with a planetary mill for 4 hours at a mass ratio of 1:3:2, dried at 120°C, and pre-fired at 1050°C (in the atmosphere) for 3 hours. The heating rate was 3°C / min, and then cooled with the furnace to obtain calcined material; the calcined material, zirconium balls, and deionized water were ball-milled with a planetary mill for 4 hours at a mass ratio of 1:3:2, and then heated at 120 After drying at ℃, microwave dielectric ceramic powder is obtained.

[0077] (2) In the microwave dielectric ceramic powder that step (1) obtains, add the binder of powder material quality 20%, granulate and grind 1h, cross 80 mesh sieves, then the powder that obtains is pressed (pressure is 100MPa) into A thin cylindrical green body with a thickness of 6mm and a diameter of 13mm is finally sintered into porcelain a...

Embodiment 2

[0083] (1) Weigh 29.95g CaCO according to x=0.15 3 , 108.95g Sm 2 o 3 , 59.75g TiO 2 and 1.35g Al 2 o 3 ; The above raw materials, zirconium balls, and deionized water are wet-milled with a planetary mill for 4 hours at a mass ratio of 1:3:2, dried at 120°C, and pre-fired at 1050°C (in the atmosphere) for 3 hours , the heating rate is 3°C / min, and then cooled with the furnace to obtain calcined material; the calcined material is mixed with additives to obtain a mixture of calcined material and additives, wherein the amount of additives is 0.5% of the mass of calcined material ; The mixture of pre-fired material and additives, zirconium balls, and deionized water are wet-milled with a planetary mill for 4 hours at a mass ratio of 1:3:2, and dried at 120°C to obtain microwave dielectric ceramic powder .

[0084] (2) In the microwave dielectric ceramic powder that step (1) obtains, add the binder of powder material quality 20%, granulate and grind 1h, cross 80 mesh sieves, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com