Special film-coated steel belt for armored cable

A technology for armored cables and steel tapes, which is applied in the field of special film-coated steel tapes for armored cables, can solve problems such as affecting the welding effect of steel tapes and tower top launchers, and achieve good moisture resistance, increased peel strength, and increased adhesion. relay effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

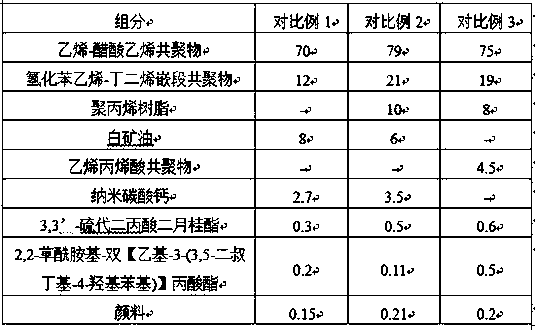

[0023] Embodiments 1 to 4: A special coated steel tape for armored cables, comprising a steel tape layer and a plastic film layer, the plastic film layer is attached to one or both of the upper and lower surfaces of the steel tape layer, and its characteristics It is: the plastic film layer includes the following parts by weight:

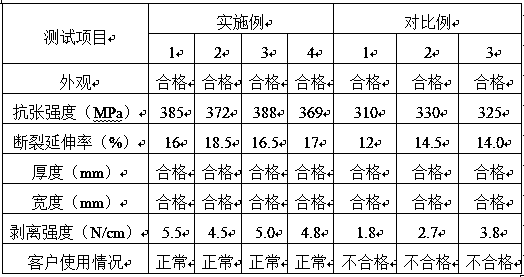

[0024] Table 1

[0025]

[0026] The content ratio of ethylene to acrylic acid in the ethylene acrylic acid copolymer is 100:5~7, the polypropylene resin is homopolypropylene, copolymer polypropylene or ethylene propylene copolymer polypropylene, and the weight part of the pigment is 0.13 ~0.21 parts, the pigment is phthalocyanine.

[0027] The plastic film layer of the special coated steel tape for the armored cable is made by the following steps:

[0028] S1. Weigh 65~80 parts of ethylene-vinyl acetate copolymer, 10~25 parts of hydrogenated styrene-butadiene block copolymer, 5~12 parts of polypropylene resin, 3~10 parts of white mineral oil, ethylene acr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com