Grouped drilling and pile implanting construction method

A construction method and technology for planting piles, applied in drilling equipment and methods, drill pipes, drill pipes, etc., can solve problems such as reducing the technical performance of implanted piles, affecting the construction efficiency of piles, and affecting the quality of prefabricated piles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

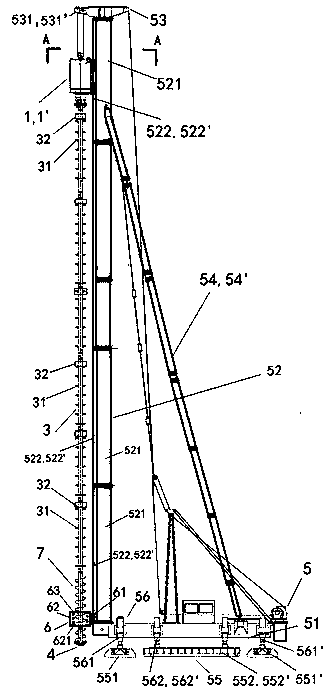

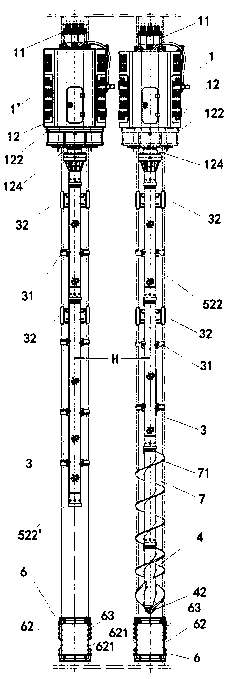

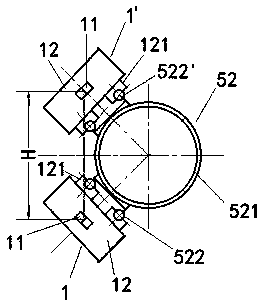

[0022] Such as Figure 1-6 As shown, a group drilling and pile planting system includes two groups of power head assemblies 1, 1', a multi-section drill pipe 3 with stirring blades 31 and arc surface protection blocks 32, a helical screw with helical blades 71 Drill pipe 7, drilling tool 4 with cutting wing 42, two support frames, walking pile frame 5 and the control system including drilling rig control system, pile frame control system and grouting control system, each group of power head assembly 1 includes lifting Pulley 11, frame 12 and grouting pipeline with back guide block 121, vertical motor and reduction box 122, reduction box 122 has hollow output shaft 124; The socket 323; the walking pile frame 5 includes a main engine chassis 51 with at least two groups of hoisting mechanisms, a jacking mechanism 56 with front and rear jacking cylinders 561,561' and left and right jacking cylinders 562,562', and two horizontal walks 551,551' and two longitudinal The walking mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com