Modified carbon fiber strain sensor device and preparation method thereof

A technology of fiber strain and sensing devices, which is applied in the field of sensing and self-sensing, can solve the problems of complex coupling response, unstable output signal, and difficulty in guaranteeing linear output, etc., achieve good dynamic response, inhibit initial creep, and inhibit preparation uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

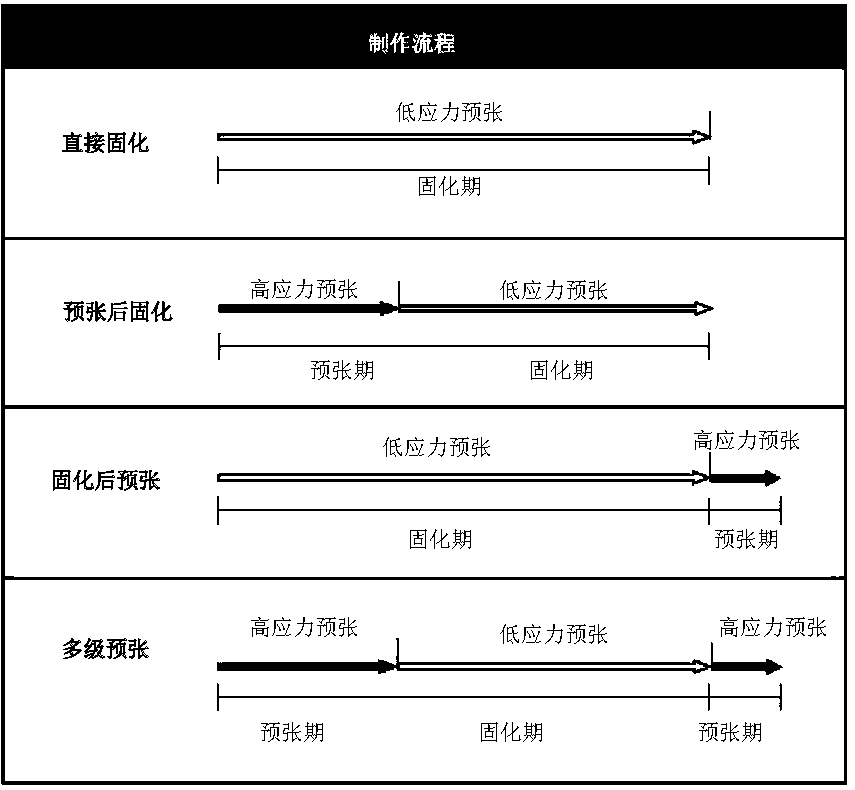

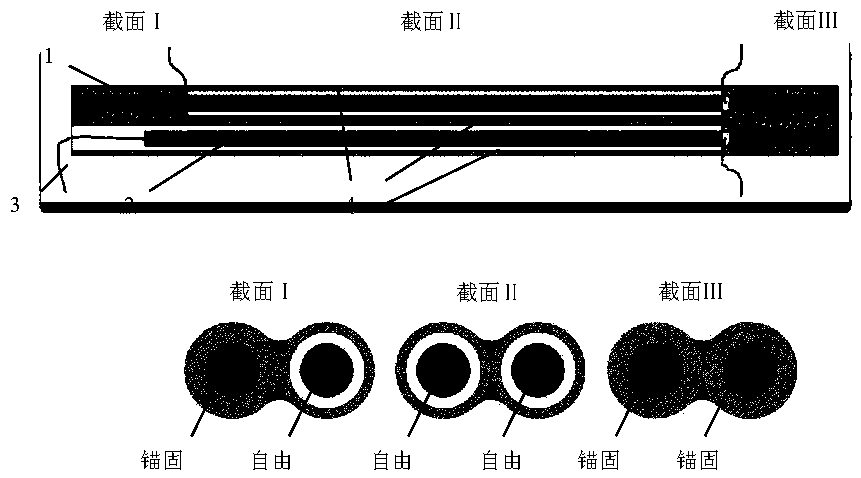

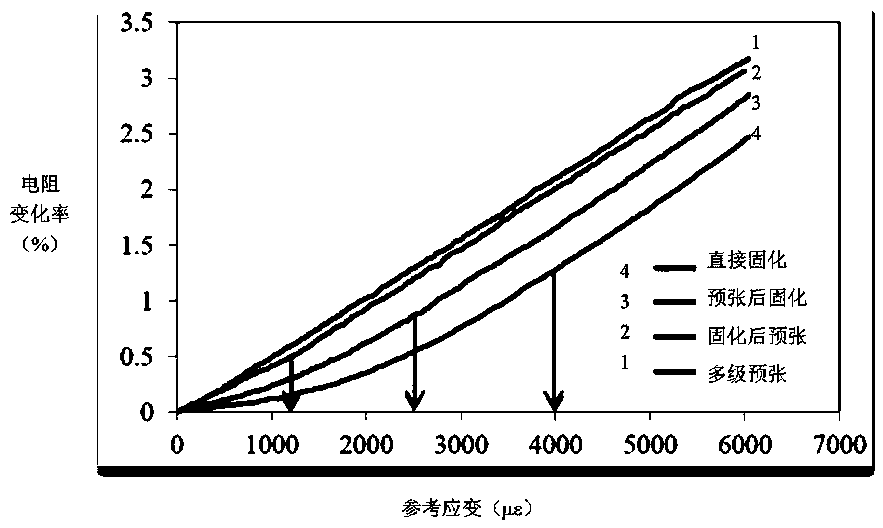

[0031] According to the production process in Figure 1, four long-gauge-length carbon fiber strain sensor devices with a gauge length of 500 mm were produced respectively. The improved long gauge carbon fiber strain sensor manufactured by the method of the invention. These 4 long-gauge carbon fiber strain sensors are installed on the same iron plate, and the output signals of these 4 sensors are respectively measured after the iron plate is stretched. The measurement results show that in the range of 1500με, the output signals of the four sensors all have good linearity, which proves that the four types of long gauge carbon fiber strain sensors all meet the linear output in the small strain range. This conclusion is consistent with the conclusion of the long gauge carbon fiber strain sensor manufactured by the original method (CN102494603A). The following will focus on the measurement results of the carbon fiber sensor manufactured by the four processes at high strain levels. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com